- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 19 Author: Site Editor Publish Time: 2022-12-15 Origin: Site

If you're an entrepreneur, inventor or business owner looking for the best manufacturing process for a new idea or product line, you've probably heard of products made from rotational molding. But how much do you really know about the Roll rotomolding machine?

Why is it important to be aware of product thickness variations during the production of rotomolding machines?

What are the product features of rotomolding machine?

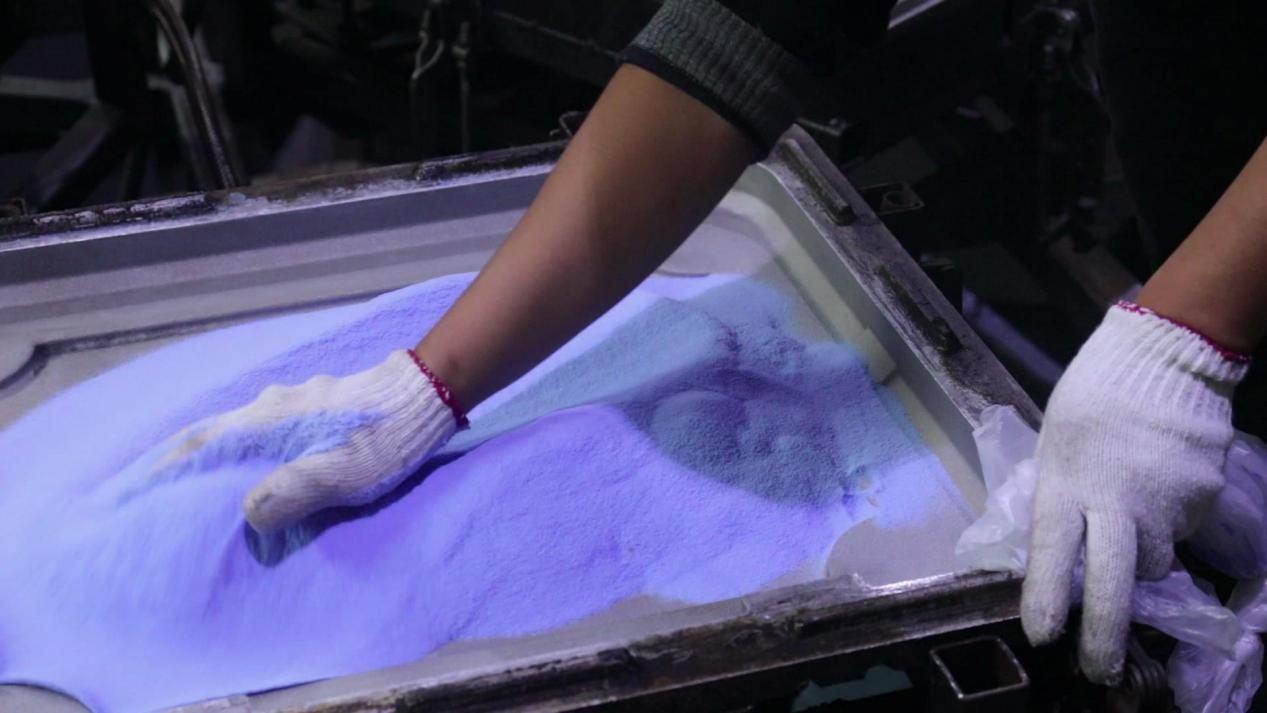

What materials are used in the production of rotomolding machines?

Variations in product thickness have a direct impact on the way rotomolded parts are dimensioned. Because wall sections can change and in many cases cannot be accurately predicted before the part is manufactured, the part must be dimensioned based on external features. If internal dimensions are required, the upper tolerance for wall thickness variation must be considered. Designers accustomed to specifying injection molded parts with controlled surfaces inside and outside the part will find this difficult to deal with. However, extrusion blow molding and double-plate thermoforming have the same limitations, while rotational molding actually maintains more uniform wall thickness than either of these competing processes.

The advantage of the rotomolding machine is that the wall thickness can be changed after the mold is made, however, it is best to keep the nominal wall thickness in mind when designing the part. The part is formed against the outer surface of the part (the inner surface of the mold) without a core, and wall thicknesses can be easily changed. Similar changes in other processes would mean extensive mold modifications. However, it should be remembered that thicker parts tend to shrink more than thinner parts and therefore may cause fit problems. In addition, thicker parts will require longer oven and cooling cycles.

All materials used in rotomolding machines need to be sufficiently resistant to oxidation, highly thermally stable and ductile. Today, the process relies heavily on polyethylene because it is readily available and easy to mold. You will need high-density polyethylene in your manufacturing process. It supports the complex design of great products, especially those used in food manufacturing.

In addition, the process involves the use of linear low-density polyethylene. This material provides high impact resistance in tanks, toys, containers and other outdoor recreational equipment. In addition, you may want to use polypropylene because of its high melting point and stress resistance.

In addition, static dissipative polyethylene is also most effective in electrical applications to protect against potentially dangerous electrical charges. Another important element is cross-linked polyethylene, which adds considerable strength to the molding process. However, these items may contain other components such as PVC plastisols, nylon and acetal. Rotational molding machines used in the manufacturing process include mold spindles, ovens and cooling chambers.

Over 15 years experience, Hangzhou Snowball I/E Co.,Ltd. two factories focus on manufacture various kind of rotomolding machines like shuttle, carrousel, rock and roll machine, as well as rotational moulds and products.