- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-3500TL

SNOWBALL

8477.4010.00

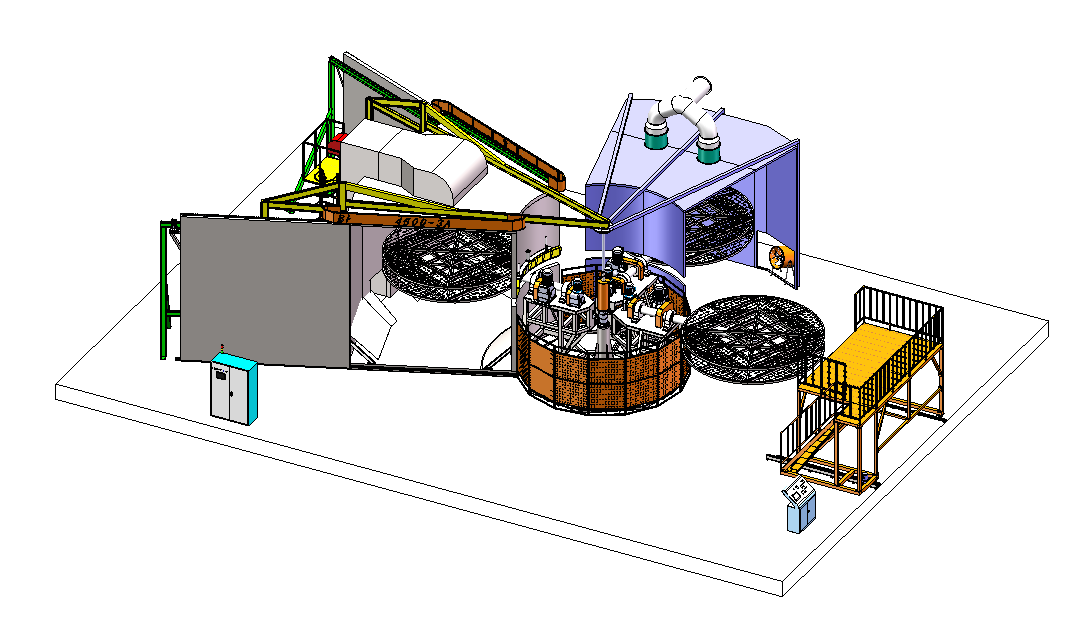

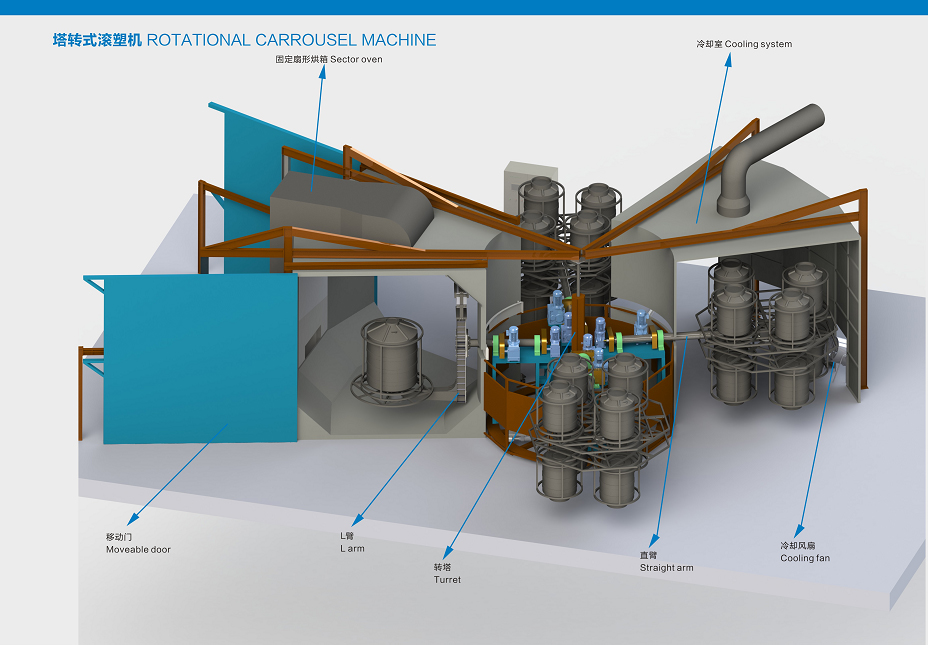

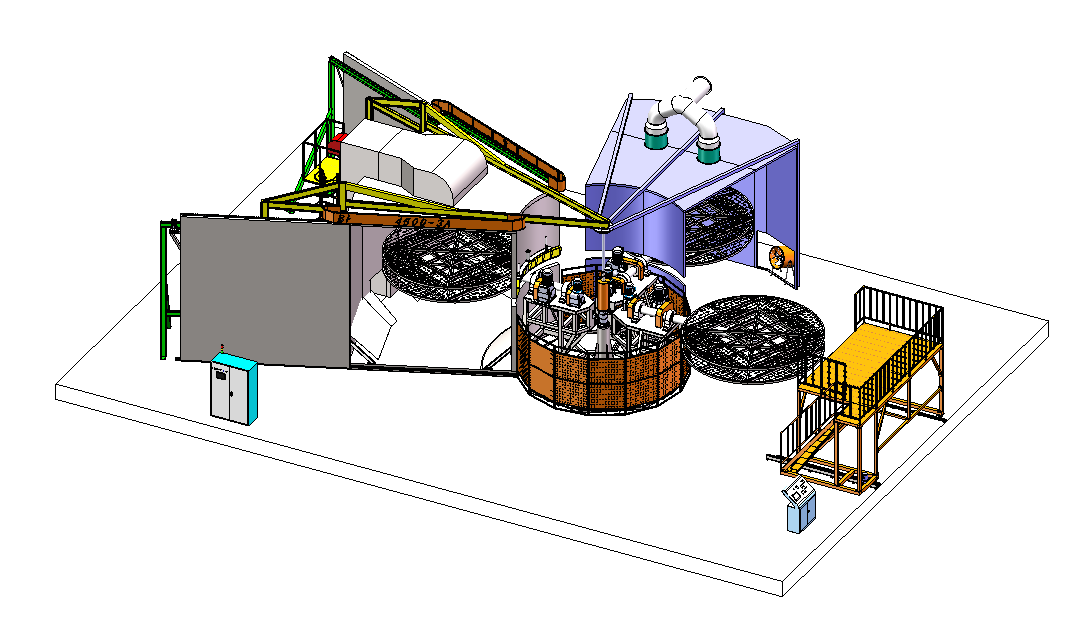

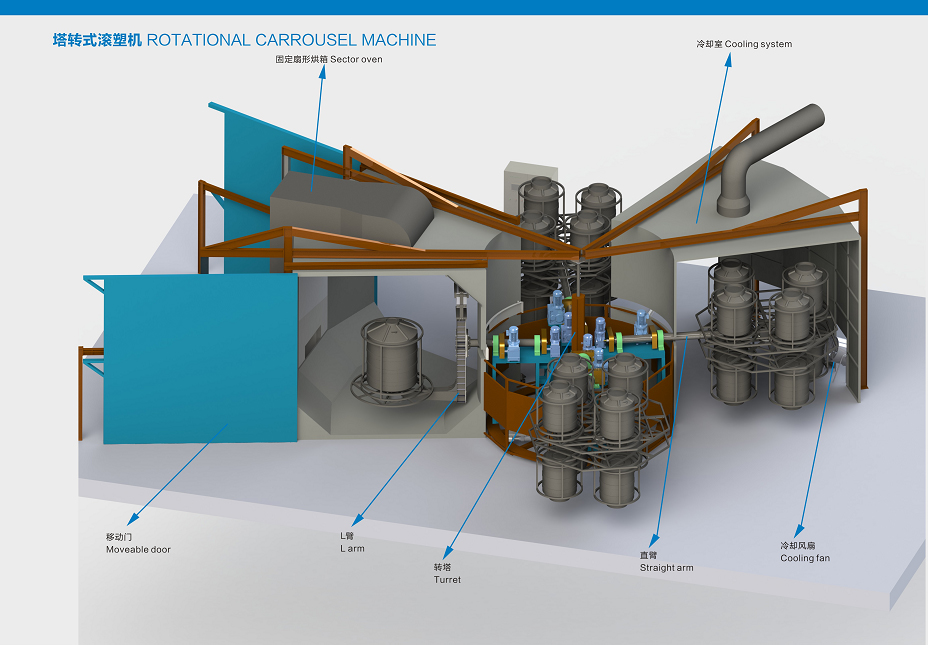

This carrousel machine is suitable for making relatively large products with different sizes but similar output. It can bear three or four arms and has three to four stations (heating, cooling, loading).It has two doors.The oven is fixed on the floor.

Benefits of using a rotational molding machine with a carousel:

1. With three workstations for heating, cooling, and disassembling molds, the machine operates efficiently, resulting in high production rates.

2. This type of machine is ideal for producing products with similar production times or mass-producing the same items.

3. An independent cooling station is available as an option, with or without a cooling chamber.

The thickness of the rotating arm is adjusted to ensure uniform ventilation. An environmental protection device is also included.

Technical data sheet:

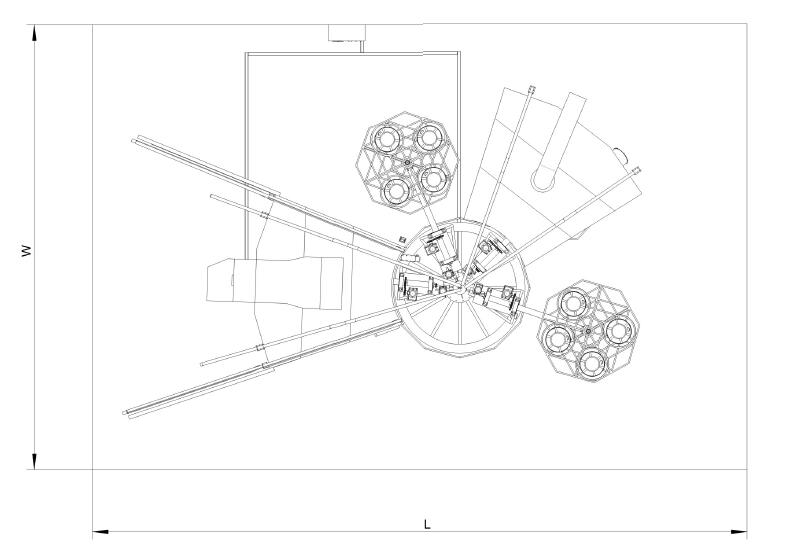

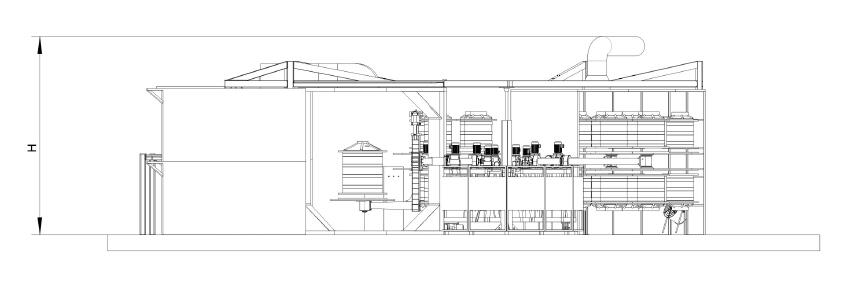

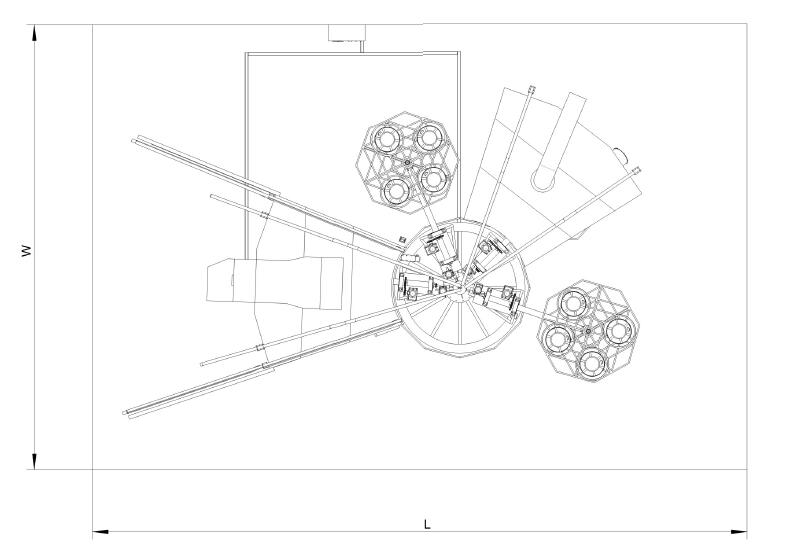

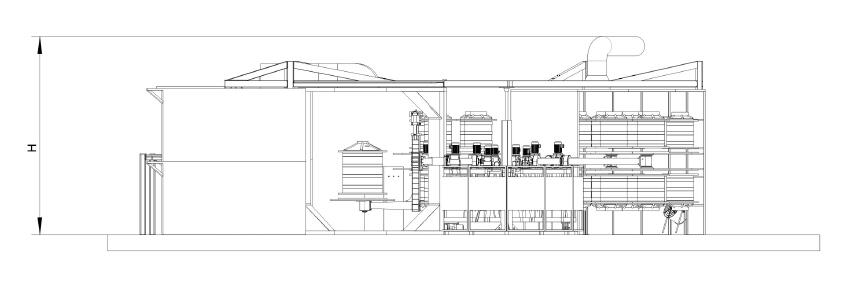

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS70 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Welcome to enquiry us! Rotate your business,Snowball your wealth!

This carrousel machine is suitable for making relatively large products with different sizes but similar output. It can bear three or four arms and has three to four stations (heating, cooling, loading).It has two doors.The oven is fixed on the floor.

Benefits of using a rotational molding machine with a carousel:

1. With three workstations for heating, cooling, and disassembling molds, the machine operates efficiently, resulting in high production rates.

2. This type of machine is ideal for producing products with similar production times or mass-producing the same items.

3. An independent cooling station is available as an option, with or without a cooling chamber.

The thickness of the rotating arm is adjusted to ensure uniform ventilation. An environmental protection device is also included.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS70 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Welcome to enquiry us! Rotate your business,Snowball your wealth!