- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-2500TL

SNOWBALL

8477.4010.00

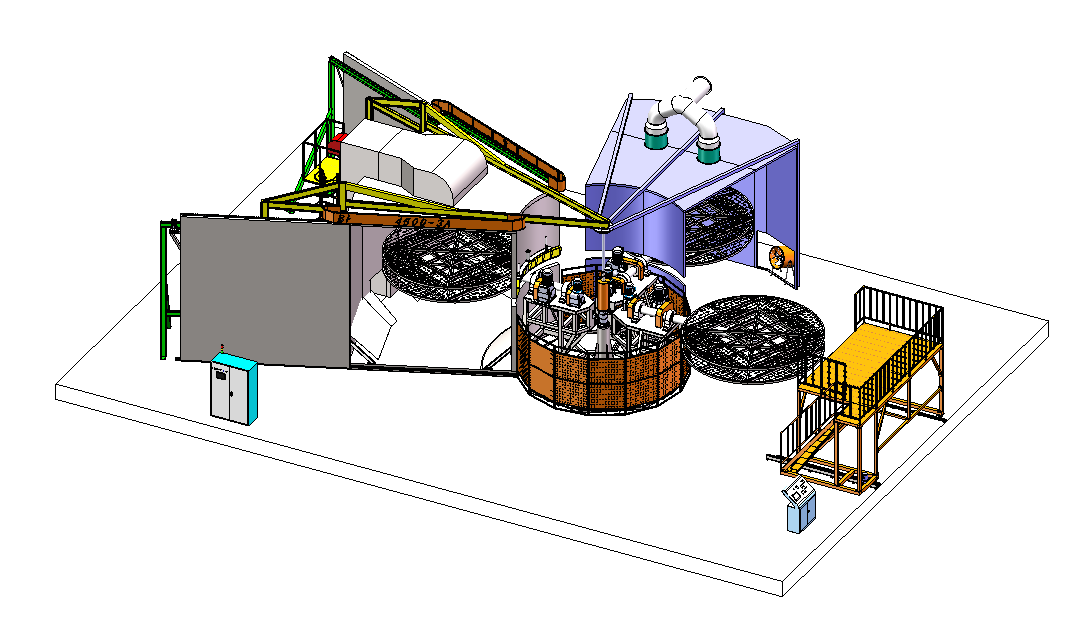

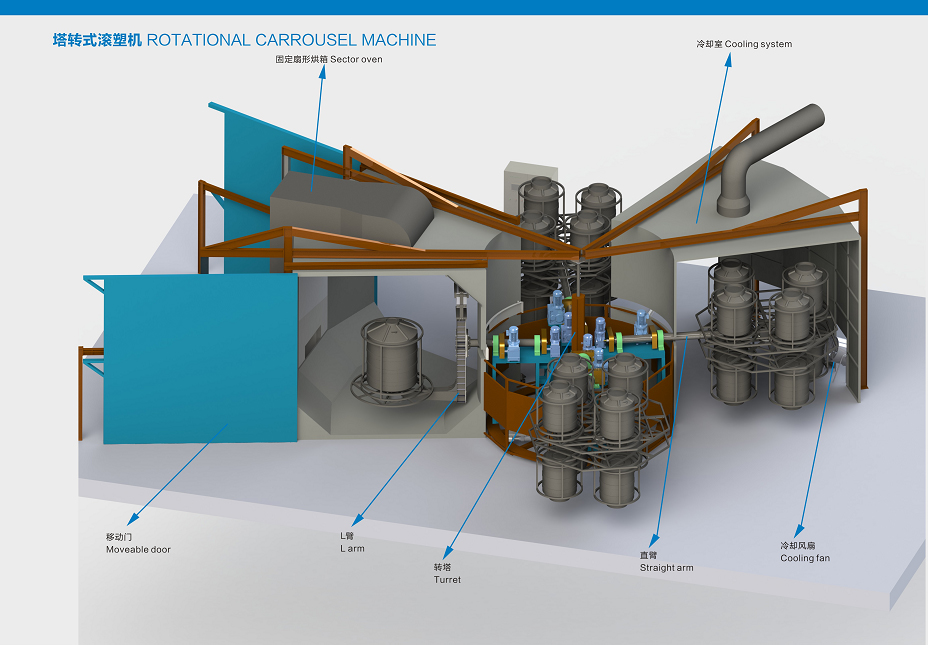

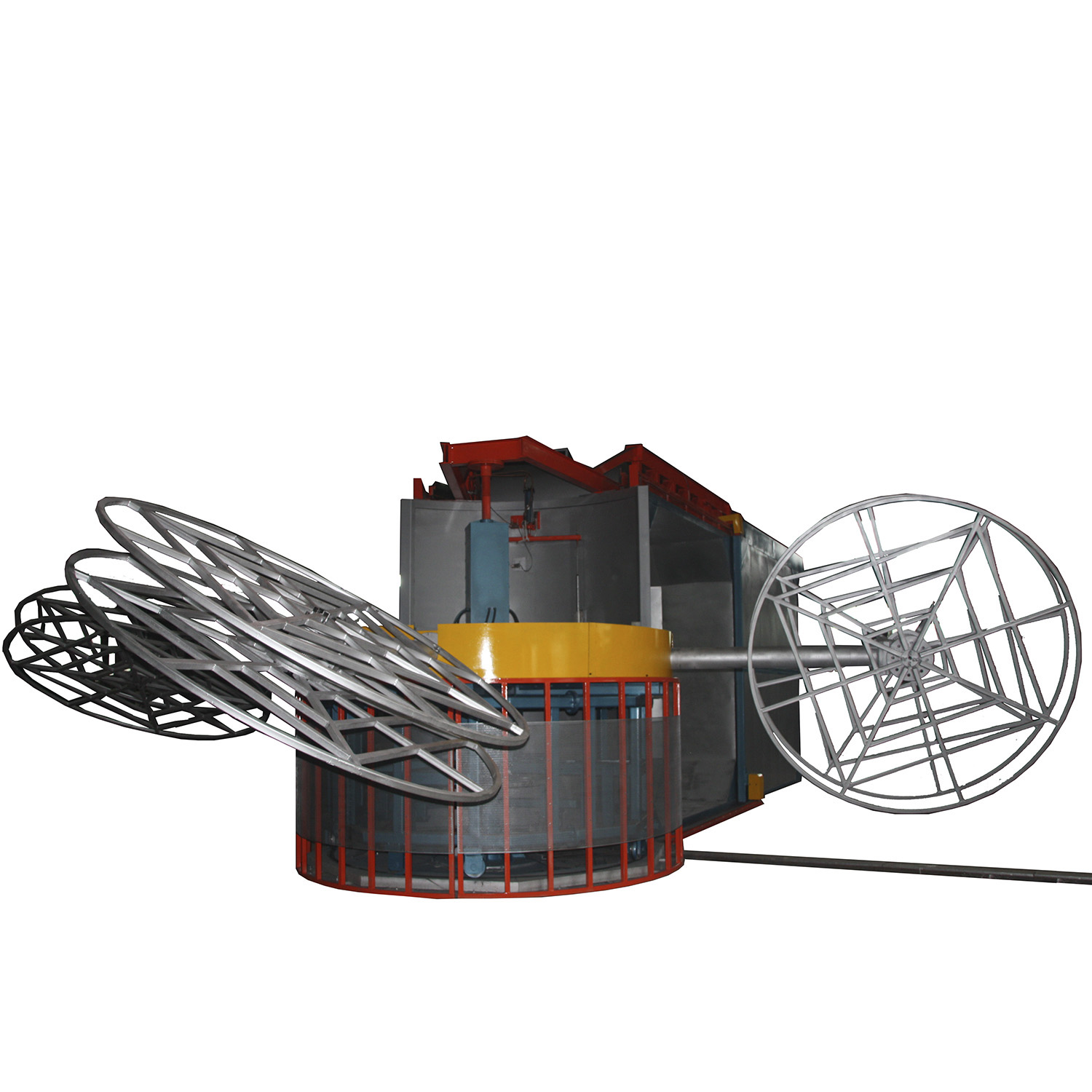

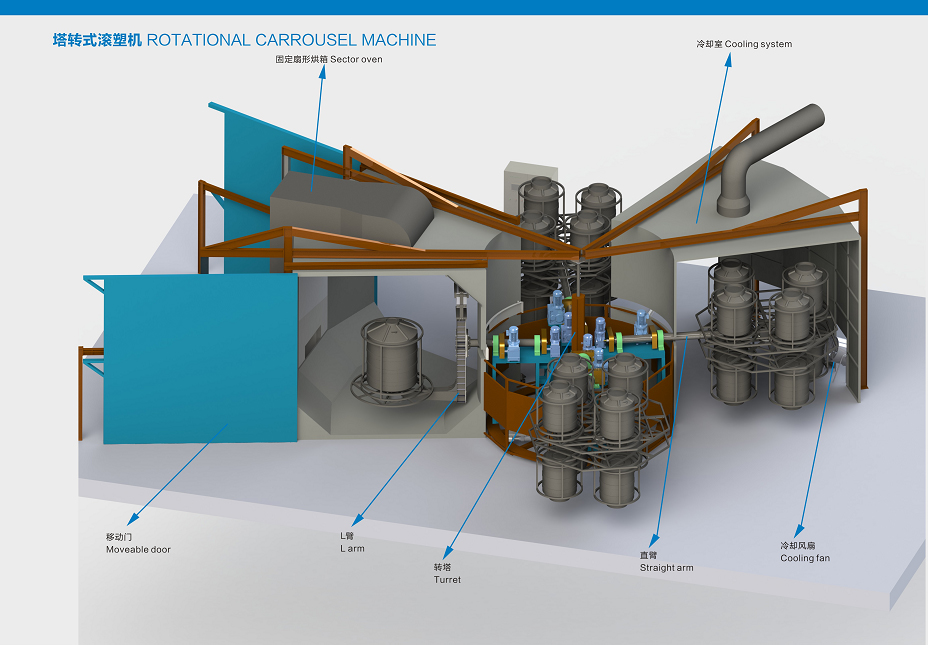

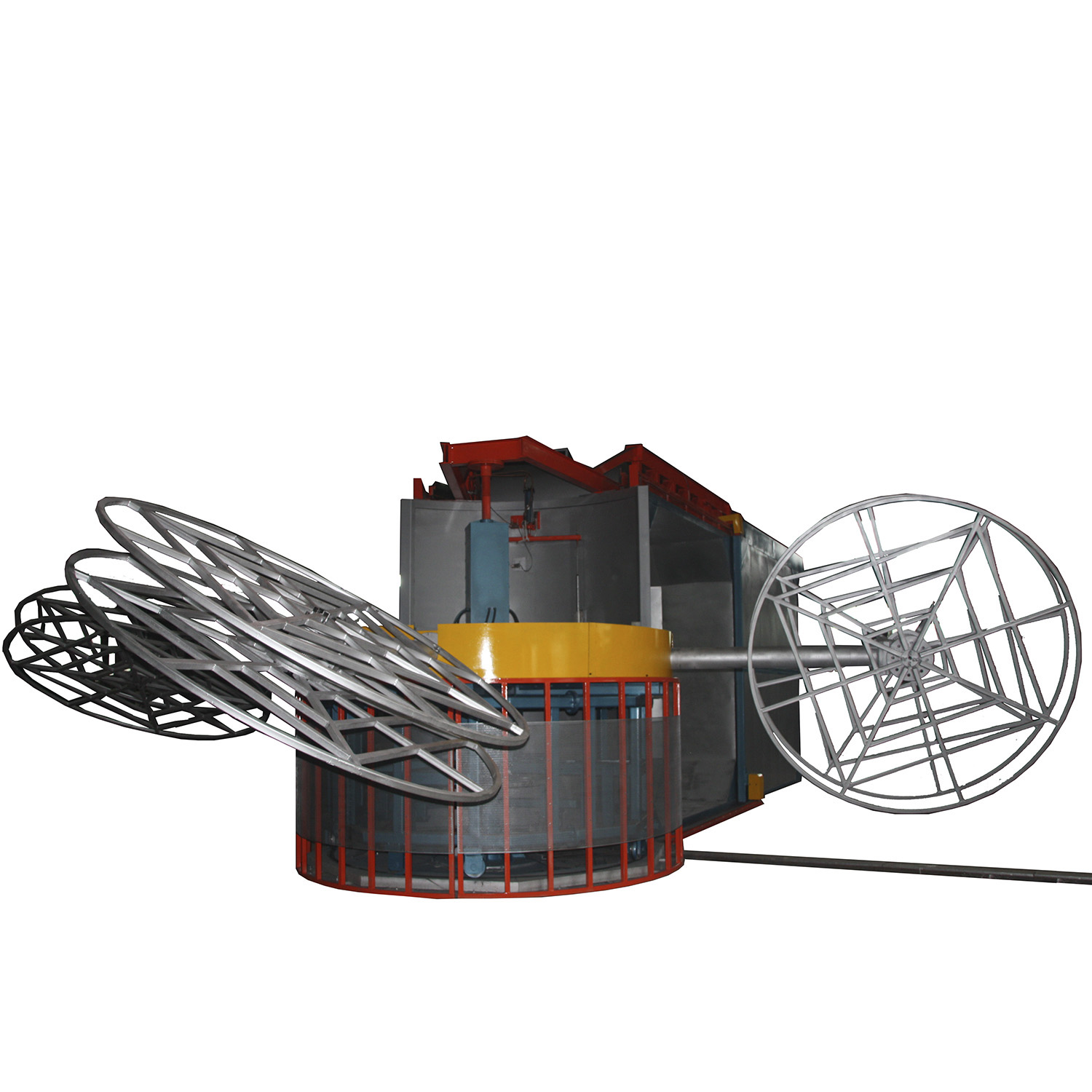

The single tower rotary machine, owing to its consistent functioning and high stability, is preferred by most clients.

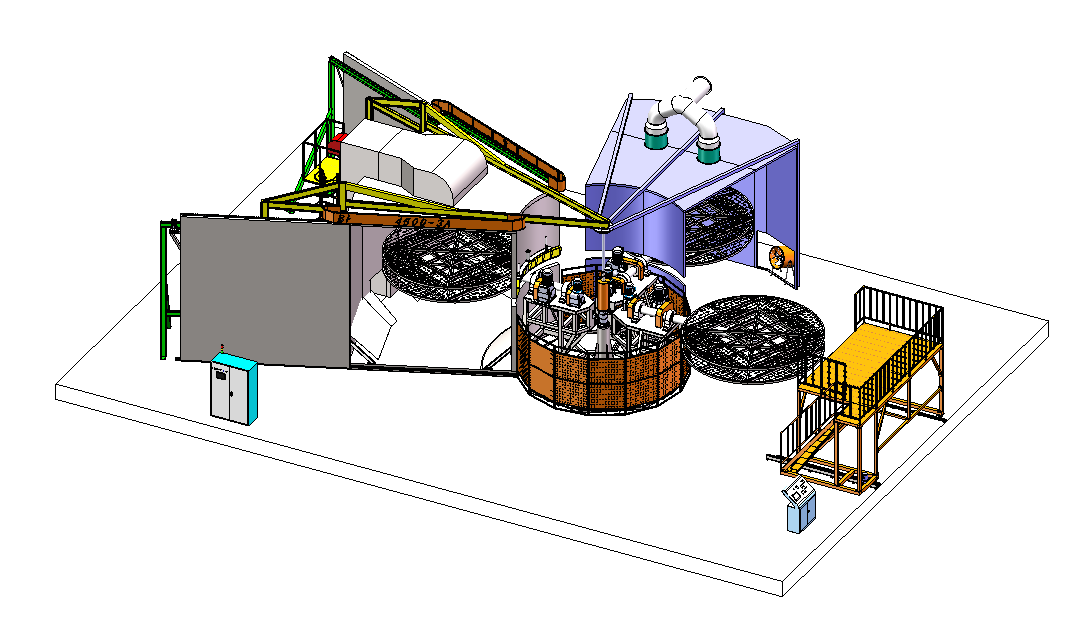

The three-arm turret machine of the rotary molding machine with central turrets and combinations of 3 mobile cars has provision for 4-station (heating, cooling, mold disassembly, preparation), and 5-station (heating, pre-cooling, cooling, mold disassembly, preparation) depending on various product requirements.

Four-arm turret rotary molding machine according to the invention with a central turret, four-carriers as claimed at least five stations from the group consisting of heating, cooling, mold disassembly, mold installation, preparation, and at least six stations being selected from heating, precooling, cooling, mold disassembly, mold installation, preparation.

The cooling system consists of a set of fans for each car. The fans are fixed to a movable metal frame which can easily be moved for most appropriate mold position.

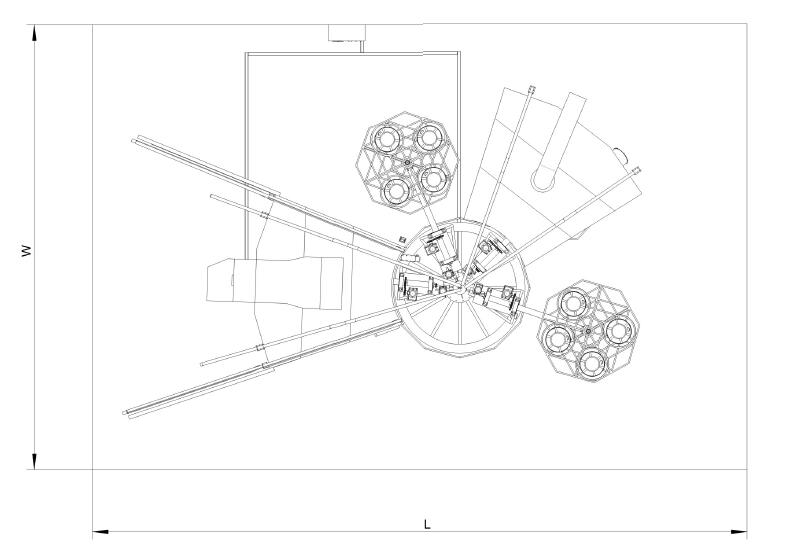

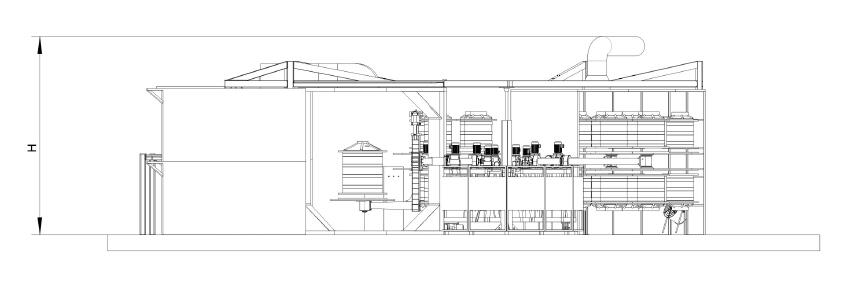

Technical data sheet:

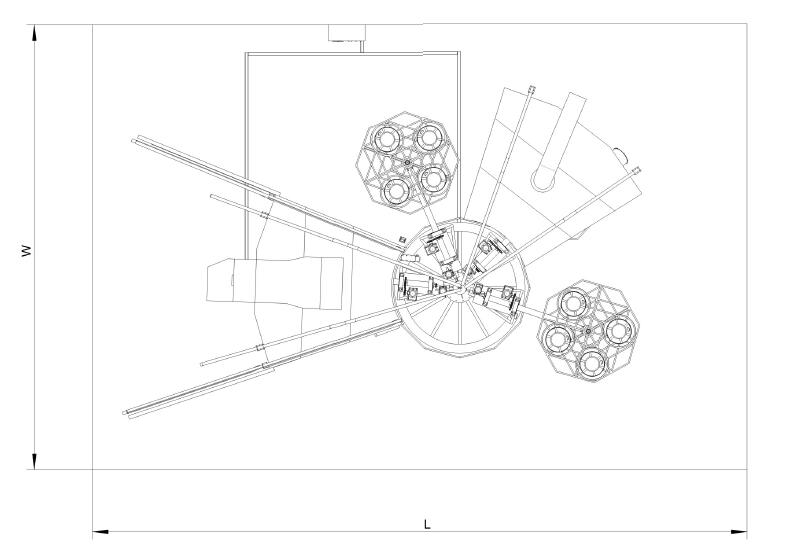

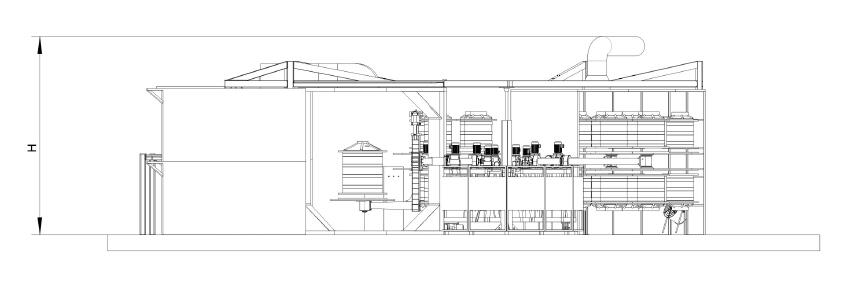

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

SNOWBALL Import and Export Co.,Ltd Profiles

Hangzhou Snowball Import and Export Co., LTD, specializes in developing, manufacturing and exporting rotomolding machines, rotational moulds and rotational molding products. We have shuttle machine, carrousel machine, rock and roll machine for the machine; and for rotational mould it includes mould for water tank, fishing boat, buoys outdoor furniture and fuel tanks. We also export assorted ranges of rotomolding products including cooler boxes, buoys, fishing boats, furniture, pallets, tanks including water tanks and fuel tanks as well as other custom made rotomolding product. Our manufacturing factory is with advanced production line; grade technical, high lever production team and comprehensive management system. Our insulated cooler box has an elegant design; superb insulation property and wide range capacity like 25L, 35L, 50L, 65L, 80L, 110L etc. We also make production base on OEM & ODM.

Our SNOWBALL brand coolers also enjoy a great reputation in streamline design, holding ice long time and wide application in camping, fishing and party. We export our rotomolding machines, moulds and product to many different countries United State, UK, Australia, Korea, Japan etc and many other countries and regions. Our slogan is "To be one-stop solution provider of rotational mould field ". Welcome to contact us, Rotate your business, Snowball your wealth.

FAQ

Q1:What is rotomolding process?

A:The rotational molding process is quite simple: A hollow mold is filled with powdered plastic resin. The mold begins rotating bi-axially and is transferred into an oven. The mold continues to rotate as the resin melts and coats the walls of the mold. The mold is cooled until the resin hardens into the desired shape.

Q2:What materials are used in rotational Moulding?

A: Rotomolding Materials Include:

Linear Low Density Polyethylene (LLDPE)

Medium Density Polyethylene (MDPE)

High Density Polyethylene (HDPE)

Low Density Polyethylene (LDPE)

Cross Link Polyethylene (XLPE)

EVA Co-polymer (EVA)

Polyvinylchloride (PVC)

Nylon.

Q3:How many types of rotational Moulding are there?

A:The types of rotational molding equipment are turret machines, shuttle machines, rock and roll machines, and open-flame machines.

Q4:Whats your companys' main products?

A:Our company is specialized in the rotational molding machines, moulds,Ice cooler box .

Q5. What is your delivery time?

A:Usually within 60 working days after sign contract and upon receipt of deposit TT transfer.

Q6. What is your payment terms?

A:50% deposit TT transfer after sign contract, and balance 50% after inspection before shipment.

Q7. How about your warrant and after-sale services?

A:All equipment unit are service one year warranty,

For electrical motor, Inverter, and PLC, we offer warranty for 18 months.

Q8. Do you test all your machine before delivery?

A: Yes, we test 100% of machine by our engineers before leave our company.

Q9. How to install and trial run when machine arrive customer's factory?

A: Due to epidemic, we could not send our technician abroad, So, now, all the

exporting equipment are designed with module function, The buyer can install the equipment

with our installation instruction easier.

If the client insists to send the technician for machine installation, they will need to pay the travel fee and accommodation fee, and labor cost USD 100 for one person in one day.

Welcome to enquiry us! Rotate your business,Snowball your wealth!

The single tower rotary machine, owing to its consistent functioning and high stability, is preferred by most clients.

The three-arm turret machine of the rotary molding machine with central turrets and combinations of 3 mobile cars has provision for 4-station (heating, cooling, mold disassembly, preparation), and 5-station (heating, pre-cooling, cooling, mold disassembly, preparation) depending on various product requirements.

Four-arm turret rotary molding machine according to the invention with a central turret, four-carriers as claimed at least five stations from the group consisting of heating, cooling, mold disassembly, mold installation, preparation, and at least six stations being selected from heating, precooling, cooling, mold disassembly, mold installation, preparation.

The cooling system consists of a set of fans for each car. The fans are fixed to a movable metal frame which can easily be moved for most appropriate mold position.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

SNOWBALL Import and Export Co.,Ltd Profiles

Hangzhou Snowball Import and Export Co., LTD, specializes in developing, manufacturing and exporting rotomolding machines, rotational moulds and rotational molding products. We have shuttle machine, carrousel machine, rock and roll machine for the machine; and for rotational mould it includes mould for water tank, fishing boat, buoys outdoor furniture and fuel tanks. We also export assorted ranges of rotomolding products including cooler boxes, buoys, fishing boats, furniture, pallets, tanks including water tanks and fuel tanks as well as other custom made rotomolding product. Our manufacturing factory is with advanced production line; grade technical, high lever production team and comprehensive management system. Our insulated cooler box has an elegant design; superb insulation property and wide range capacity like 25L, 35L, 50L, 65L, 80L, 110L etc. We also make production base on OEM & ODM.

Our SNOWBALL brand coolers also enjoy a great reputation in streamline design, holding ice long time and wide application in camping, fishing and party. We export our rotomolding machines, moulds and product to many different countries United State, UK, Australia, Korea, Japan etc and many other countries and regions. Our slogan is "To be one-stop solution provider of rotational mould field ". Welcome to contact us, Rotate your business, Snowball your wealth.

FAQ

Q1:What is rotomolding process?

A:The rotational molding process is quite simple: A hollow mold is filled with powdered plastic resin. The mold begins rotating bi-axially and is transferred into an oven. The mold continues to rotate as the resin melts and coats the walls of the mold. The mold is cooled until the resin hardens into the desired shape.

Q2:What materials are used in rotational Moulding?

A: Rotomolding Materials Include:

Linear Low Density Polyethylene (LLDPE)

Medium Density Polyethylene (MDPE)

High Density Polyethylene (HDPE)

Low Density Polyethylene (LDPE)

Cross Link Polyethylene (XLPE)

EVA Co-polymer (EVA)

Polyvinylchloride (PVC)

Nylon.

Q3:How many types of rotational Moulding are there?

A:The types of rotational molding equipment are turret machines, shuttle machines, rock and roll machines, and open-flame machines.

Q4:Whats your companys' main products?

A:Our company is specialized in the rotational molding machines, moulds,Ice cooler box .

Q5. What is your delivery time?

A:Usually within 60 working days after sign contract and upon receipt of deposit TT transfer.

Q6. What is your payment terms?

A:50% deposit TT transfer after sign contract, and balance 50% after inspection before shipment.

Q7. How about your warrant and after-sale services?

A:All equipment unit are service one year warranty,

For electrical motor, Inverter, and PLC, we offer warranty for 18 months.

Q8. Do you test all your machine before delivery?

A: Yes, we test 100% of machine by our engineers before leave our company.

Q9. How to install and trial run when machine arrive customer's factory?

A: Due to epidemic, we could not send our technician abroad, So, now, all the

exporting equipment are designed with module function, The buyer can install the equipment

with our installation instruction easier.

If the client insists to send the technician for machine installation, they will need to pay the travel fee and accommodation fee, and labor cost USD 100 for one person in one day.

Welcome to enquiry us! Rotate your business,Snowball your wealth!