- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 21 Author: Site Editor Publish Time: 2022-12-05 Origin: Site

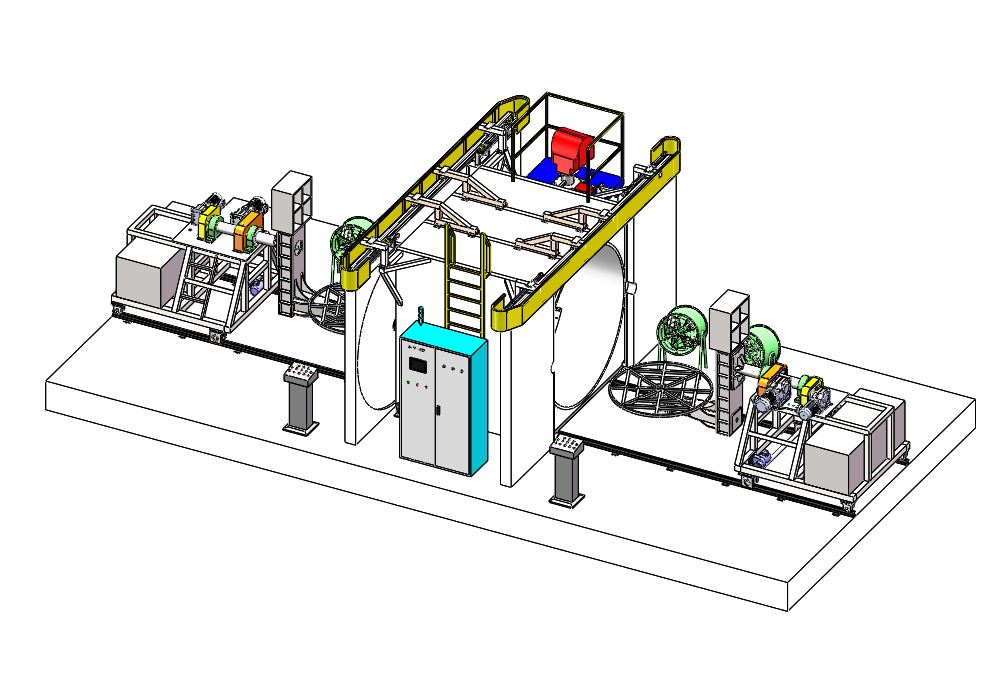

The rotomolding machine has three stages: loading and unloading, a gas furnace that generates high temperatures, and a cooling station.

What are the characteristics of the rotomolding machine?

Why do we need to use the rotomolding machine?

What are the types and characteristics of rotomolding machine equipment?

1. rotomolding machines and molds have many options and strong adaptability. Rotomolding can produce fully enclosed products, and can also form large and super-large plastic hollow products.

2. The rotomolding machine is formed at one time, without internal stress, not easily deformed, and without seams. The edge strength of the rotomolded product is good, and the thickness of the product edge can exceed 5 mm, which can solve the problem of the thin edge of the hollow product; no need to adjust the mold, rotomolding The wall thickness of the product can be adjusted appropriately (above 2mm).

3. The shape of rotomolding products can be very complex, and the wall thickness can exceed 5 mm, and the product strength is high.

1. It is suitable for the production of multi-variety and small-batch plastic products, and it is easy to change the color of the products.

2. In the rotomolding process, there are no wastes such as runners and gates, and there is almost no return material in the production process. The wall thickness of the product is relatively uniform, so the efficiency of the material can be fully utilized, so this process is extremely efficient for the material. High, which is conducive to saving raw materials.

1. Turret Dobby rotomolding machine

Turret equipment is a turntable with three (or four) arms that can carry molds, cyclically working on three (or four) workstations around a central point. Because the mechanical arm is on a turntable, this equipment is suitable for producing products with consistent product processing cycles.

2. Independent dobby rotomolding machine

The independent multi-arm rotomolding equipment consists of three (or four) arms mounted on three relatively independent turntables. The three turntables can rotate independently around a center, so that one arm will not affect other arms when entering the next workstation. location and processing. The independent arm configuration is more flexible during the molding process.

3. Shuttle double-arm rotomolding machine

The comb-type double-arm equipment is a linear combination, the middle is the combustion chamber, and the two sides are the cooling chamber and the loading and unloading position. The robotic arm can carry heavier molds, suitable for manufacturing larger products, and the equipment is easy to maintain. The size of the combustion chamber can be designed and manufactured according to customer needs.

4. Direct-fired rocking rotomolding machine

The direct-fired swinging equipment is produced by rotating the mold up and down, left and right, and directly heated by an open flame. The equipment has a low cost of use and is suitable for manufacturing large and super-large plastic hollow products.

SNOWBALL Hangzhou Snowball I/E Co.,Ltd. has various rotomolding machines that can provide the increasing of products, and make them more effective, reliable, and consistent.