- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-5500TL-4A

SNOWBALL

8477.4010.00

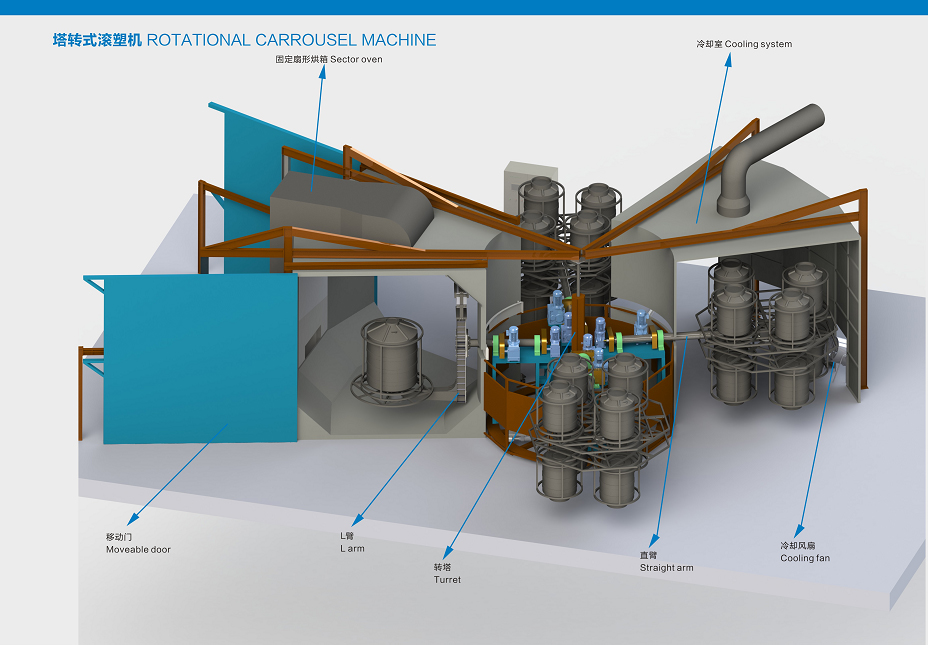

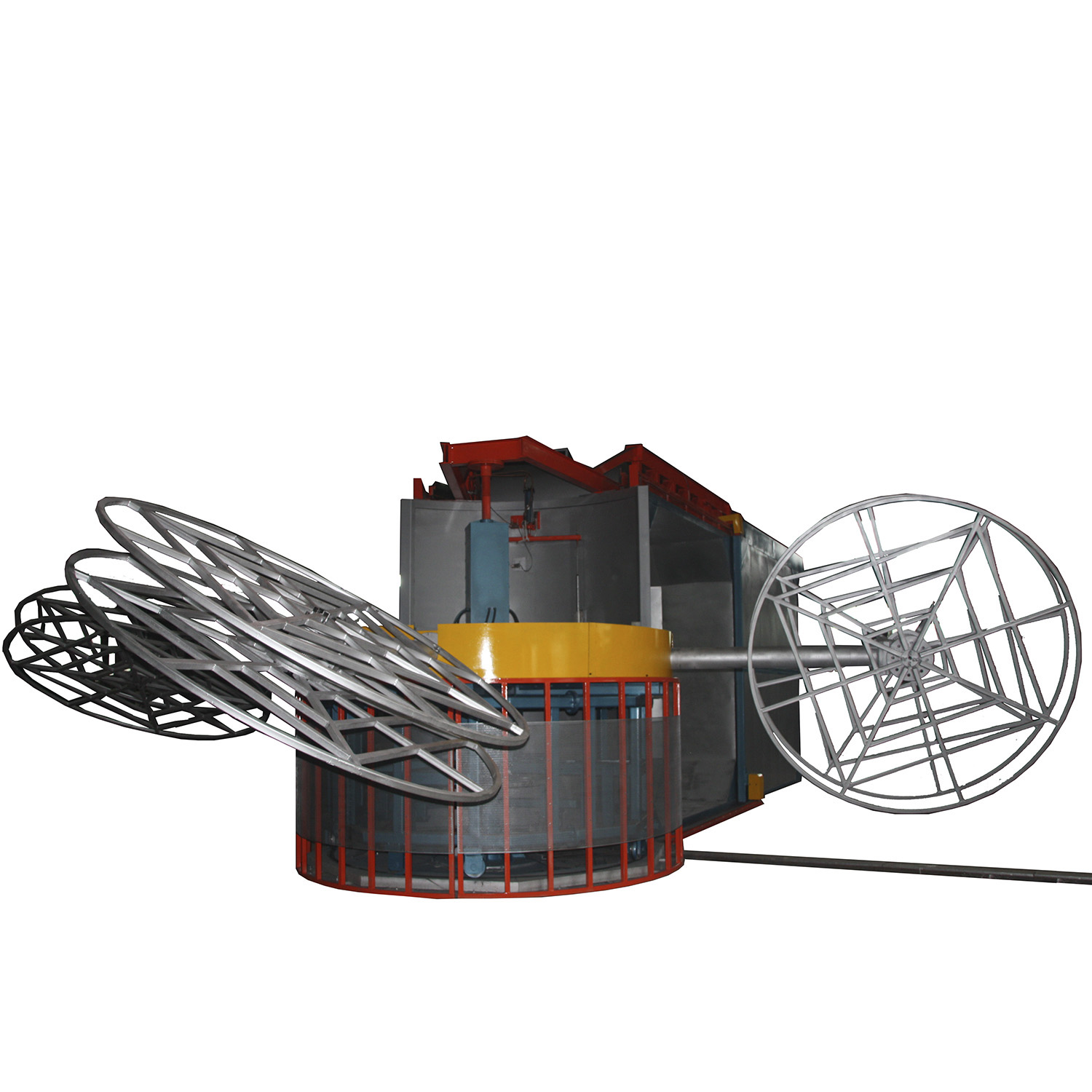

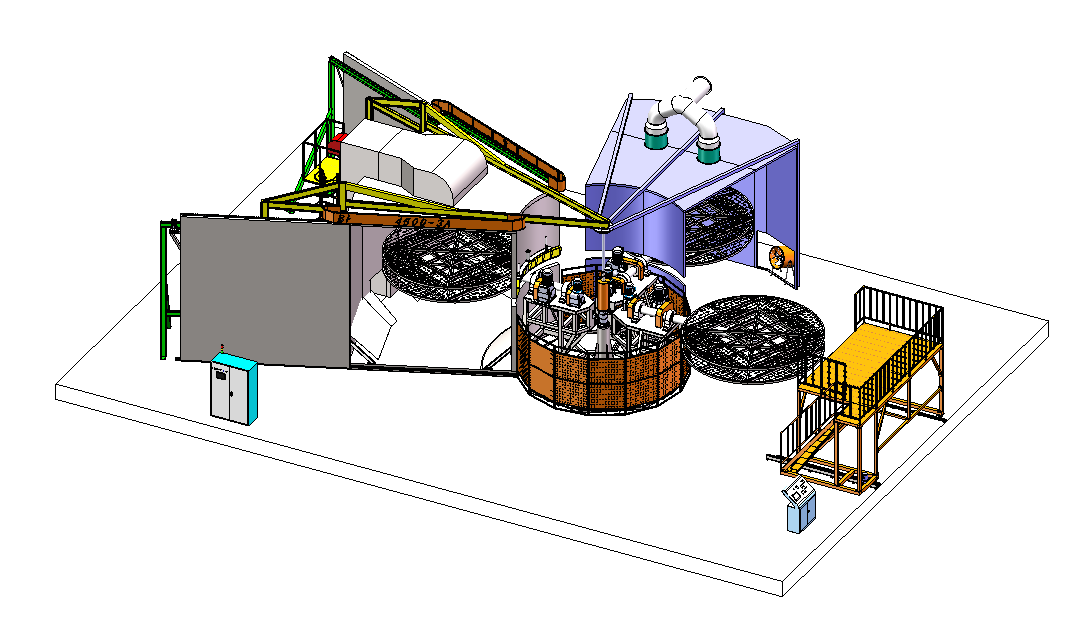

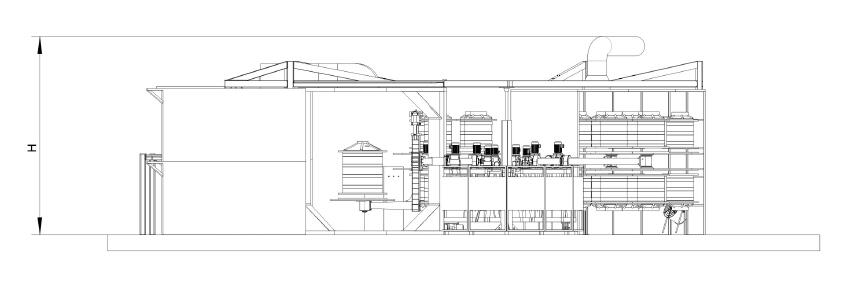

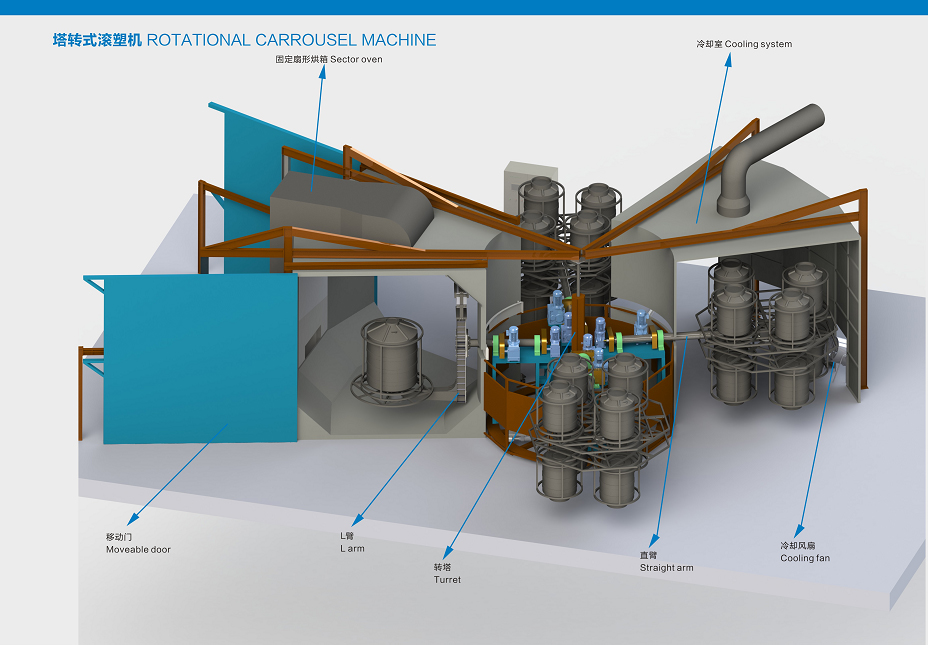

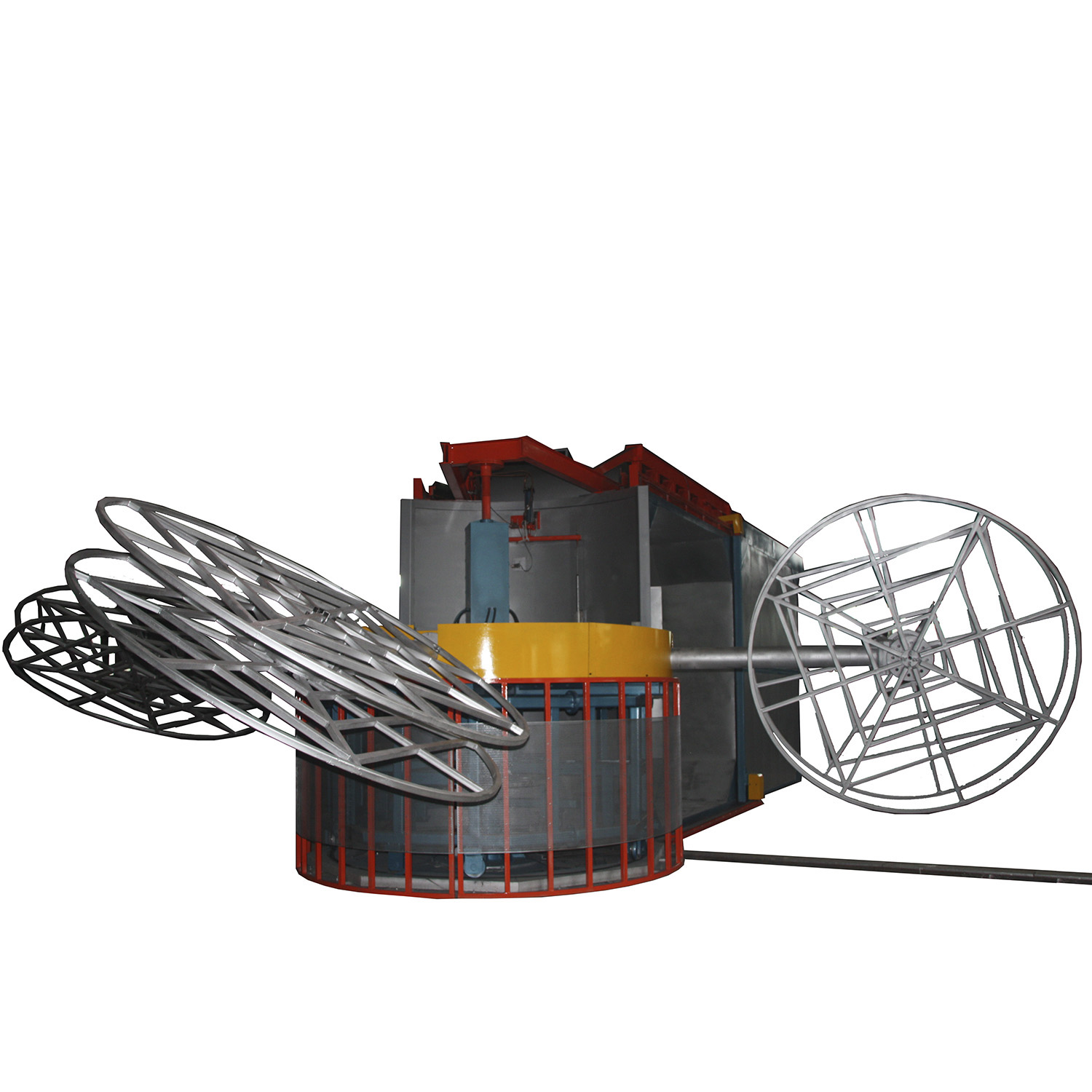

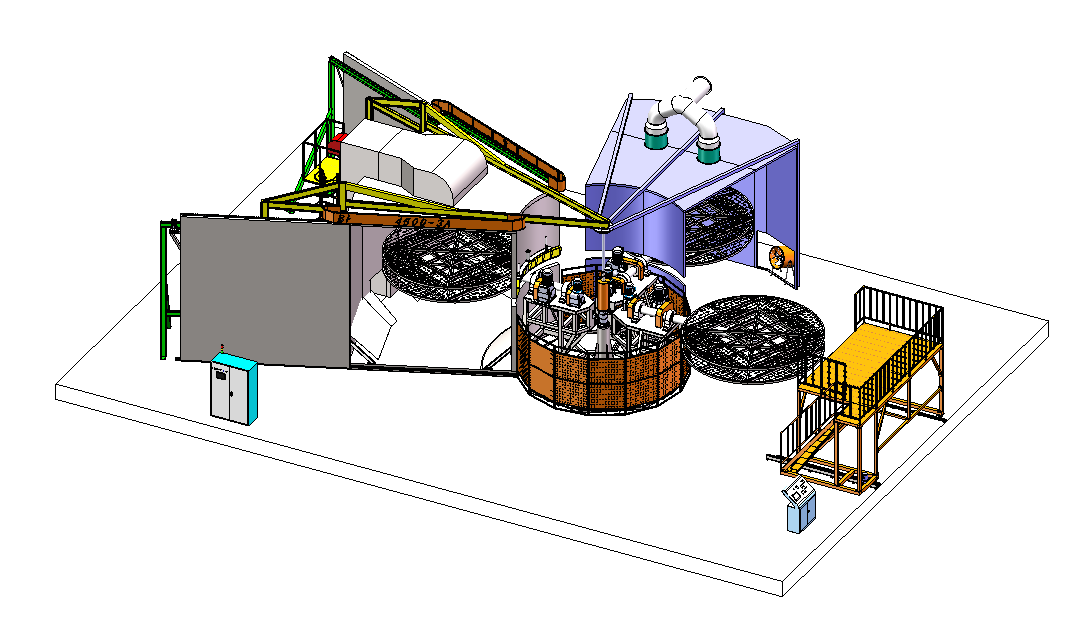

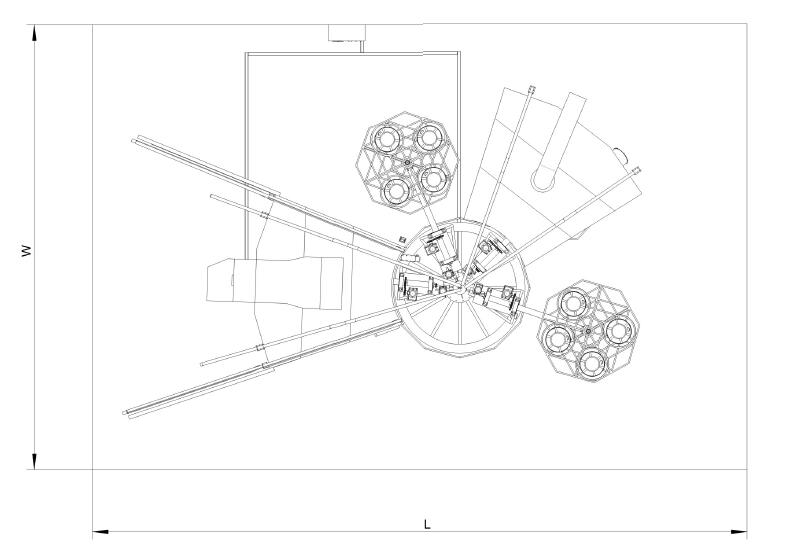

This carrousel machine is suitable for making relatively large products with different sizes but similar output. It can bear three or four arms and has three to four stations (heating, cooling, loading).It has two doors.The oven is fixed on the floor.

Introducing the Carousel Rotational Molding Machine, the perfect solution for producing large-scale plastic hollow products with precision and efficiency. This advanced machine boasts a range of impressive features, making it the ideal choice for manufacturing water tanks, septic tanks, and children's slides.

With its innovative rotational molding technology, the Carousel machine is capable of producing high-quality, seamless plastic products with consistent wall thickness and strength. Its large capacity allows for the production of products up to 10 feet in size, making it a versatile and reliable option for businesses of all sizes.

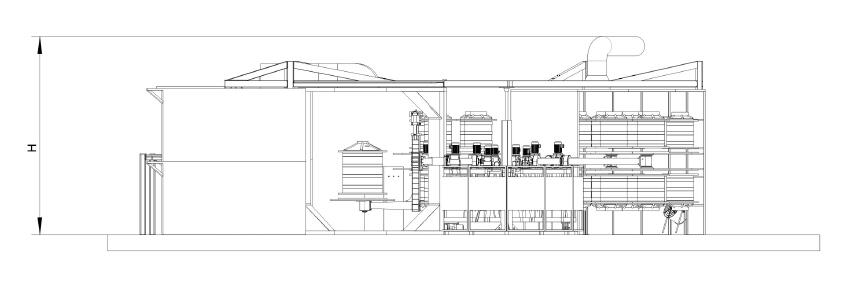

The Carousel machine is designed with user-friendliness in mind, featuring intuitive controls and a durable, low-maintenance construction. Its advanced heating system ensures even heat distribution throughout the molding process, resulting in high-quality finished products every time.

Investing in the Carousel Rotational Molding Machine means investing in a reliable and efficient solution for producing large-scale plastic hollow products. With its impressive features and professional-grade construction, this machine is sure to meet the needs of your business and exceed your expectations.

Technical data sheet:

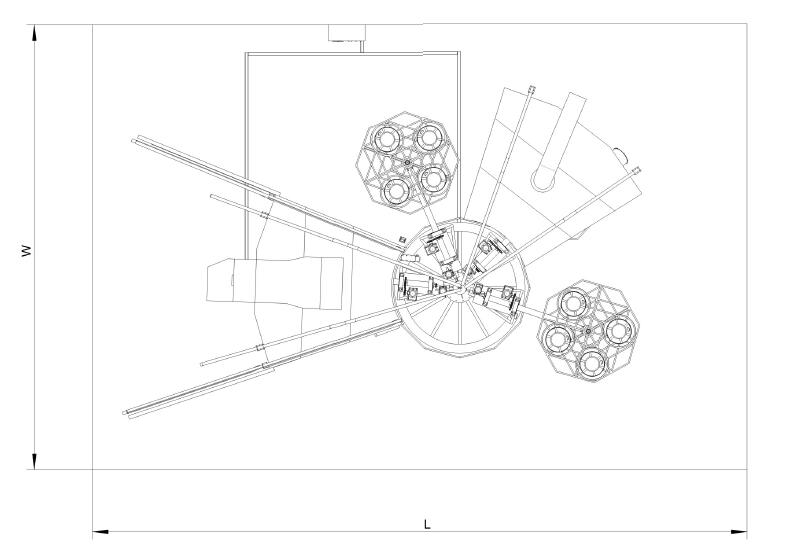

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

This carrousel machine is suitable for making relatively large products with different sizes but similar output. It can bear three or four arms and has three to four stations (heating, cooling, loading).It has two doors.The oven is fixed on the floor.

Introducing the Carousel Rotational Molding Machine, the perfect solution for producing large-scale plastic hollow products with precision and efficiency. This advanced machine boasts a range of impressive features, making it the ideal choice for manufacturing water tanks, septic tanks, and children's slides.

With its innovative rotational molding technology, the Carousel machine is capable of producing high-quality, seamless plastic products with consistent wall thickness and strength. Its large capacity allows for the production of products up to 10 feet in size, making it a versatile and reliable option for businesses of all sizes.

The Carousel machine is designed with user-friendliness in mind, featuring intuitive controls and a durable, low-maintenance construction. Its advanced heating system ensures even heat distribution throughout the molding process, resulting in high-quality finished products every time.

Investing in the Carousel Rotational Molding Machine means investing in a reliable and efficient solution for producing large-scale plastic hollow products. With its impressive features and professional-grade construction, this machine is sure to meet the needs of your business and exceed your expectations.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |