- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-φ2300x5500

SNOWBALL

8477.4010.00

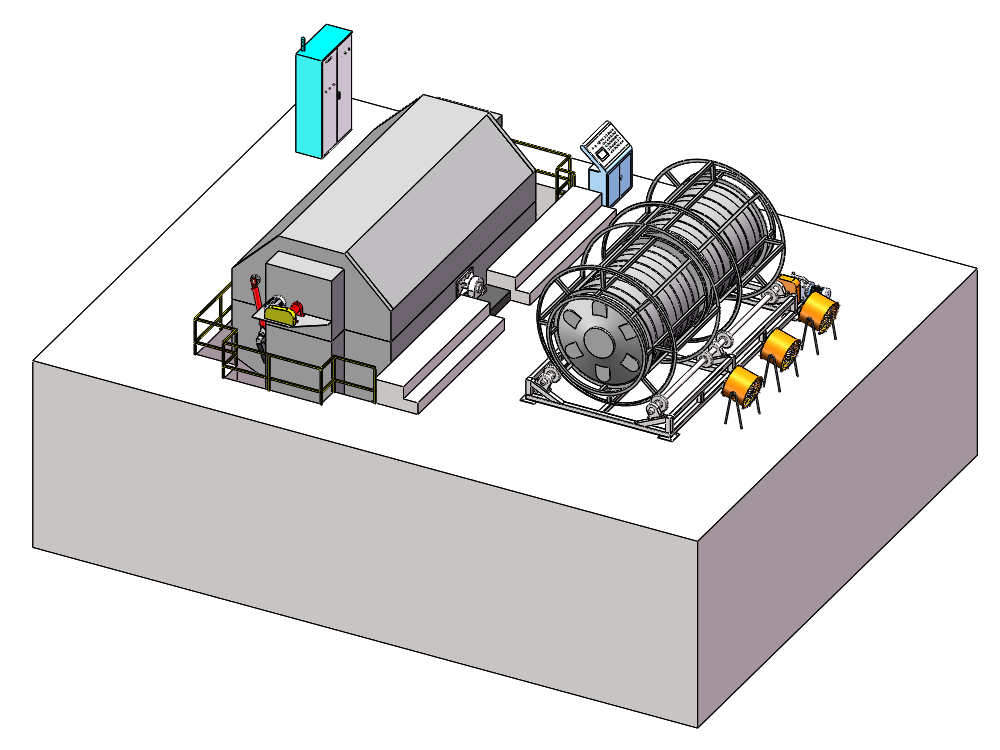

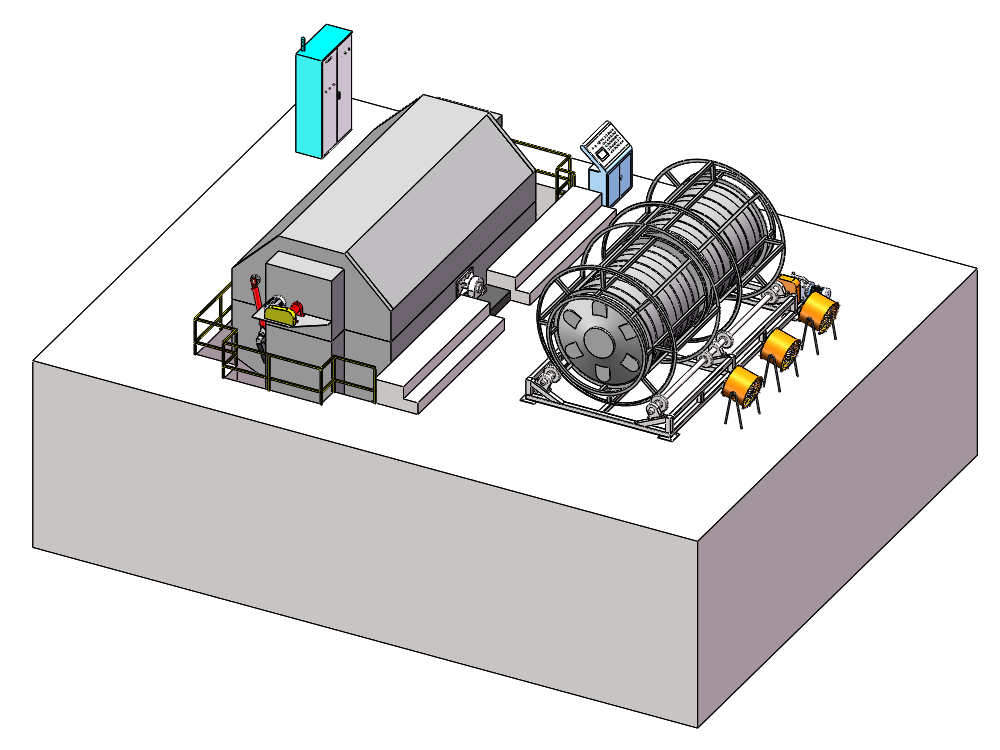

This kind of rock and roll machine is suitable to produce large long and thin mold, like kayak, boat etc.It is energy efficient,easy and the operation is simple by touching screen and full automatic control.

Advantages:

Oven type rock n roll rotational moulding machine,was developed according to the requirements of specific products. This machine can produce thick-walled, large-scale, oversize rotational moulding products like yacht, ship, missile box, plastic-lined steel plastic.

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Rock and roll rotomolding machines offer several advantages over other types of rotomolding machines:

1. Versatility: Rock and roll machines are highly versatile and can produce a wide range of products, including large and complex shapes. They are suitable for manufacturing items such as tanks, containers, playground equipment, automotive parts, and more.

2. Uniform wall thickness: Rock and roll machines provide excellent control over the wall thickness of the molded products. The rocking motion ensures even distribution of the melted plastic material, resulting in consistent wall thickness throughout the product.

3. Reduced material waste: The rocking motion of the machine helps to minimize material waste during the molding process. It ensures that the plastic material is evenly distributed and adheres to the mold surface, reducing the likelihood of material pooling or thin spots.

4. Enhanced strength and durability: The rocking motion in rock and roll machines helps to improve the strength and durability of the molded products. It allows for better fusion of the plastic material, resulting in stronger and more robust finished products.

This kind of rock and roll machine is suitable to produce large long and thin mold, like kayak, boat etc.It is energy efficient,easy and the operation is simple by touching screen and full automatic control.

Advantages:

Oven type rock n roll rotational moulding machine,was developed according to the requirements of specific products. This machine can produce thick-walled, large-scale, oversize rotational moulding products like yacht, ship, missile box, plastic-lined steel plastic.

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Rock and roll rotomolding machines offer several advantages over other types of rotomolding machines:

1. Versatility: Rock and roll machines are highly versatile and can produce a wide range of products, including large and complex shapes. They are suitable for manufacturing items such as tanks, containers, playground equipment, automotive parts, and more.

2. Uniform wall thickness: Rock and roll machines provide excellent control over the wall thickness of the molded products. The rocking motion ensures even distribution of the melted plastic material, resulting in consistent wall thickness throughout the product.

3. Reduced material waste: The rocking motion of the machine helps to minimize material waste during the molding process. It ensures that the plastic material is evenly distributed and adheres to the mold surface, reducing the likelihood of material pooling or thin spots.

4. Enhanced strength and durability: The rocking motion in rock and roll machines helps to improve the strength and durability of the molded products. It allows for better fusion of the plastic material, resulting in stronger and more robust finished products.