- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

SN-4000TL

SNOWBALL

8477.4010.00

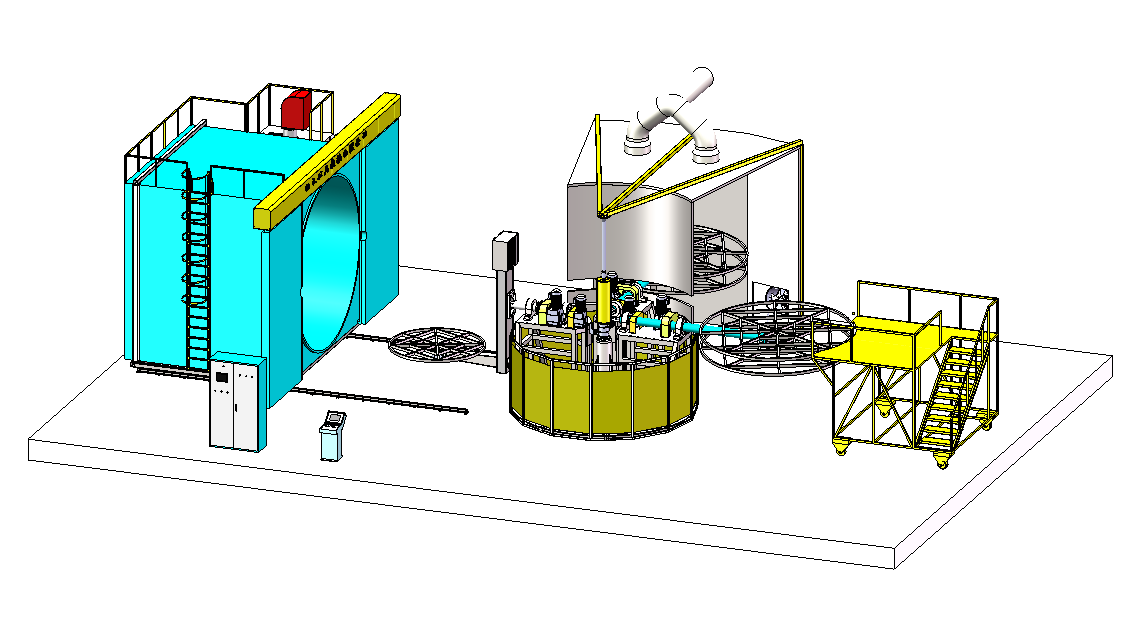

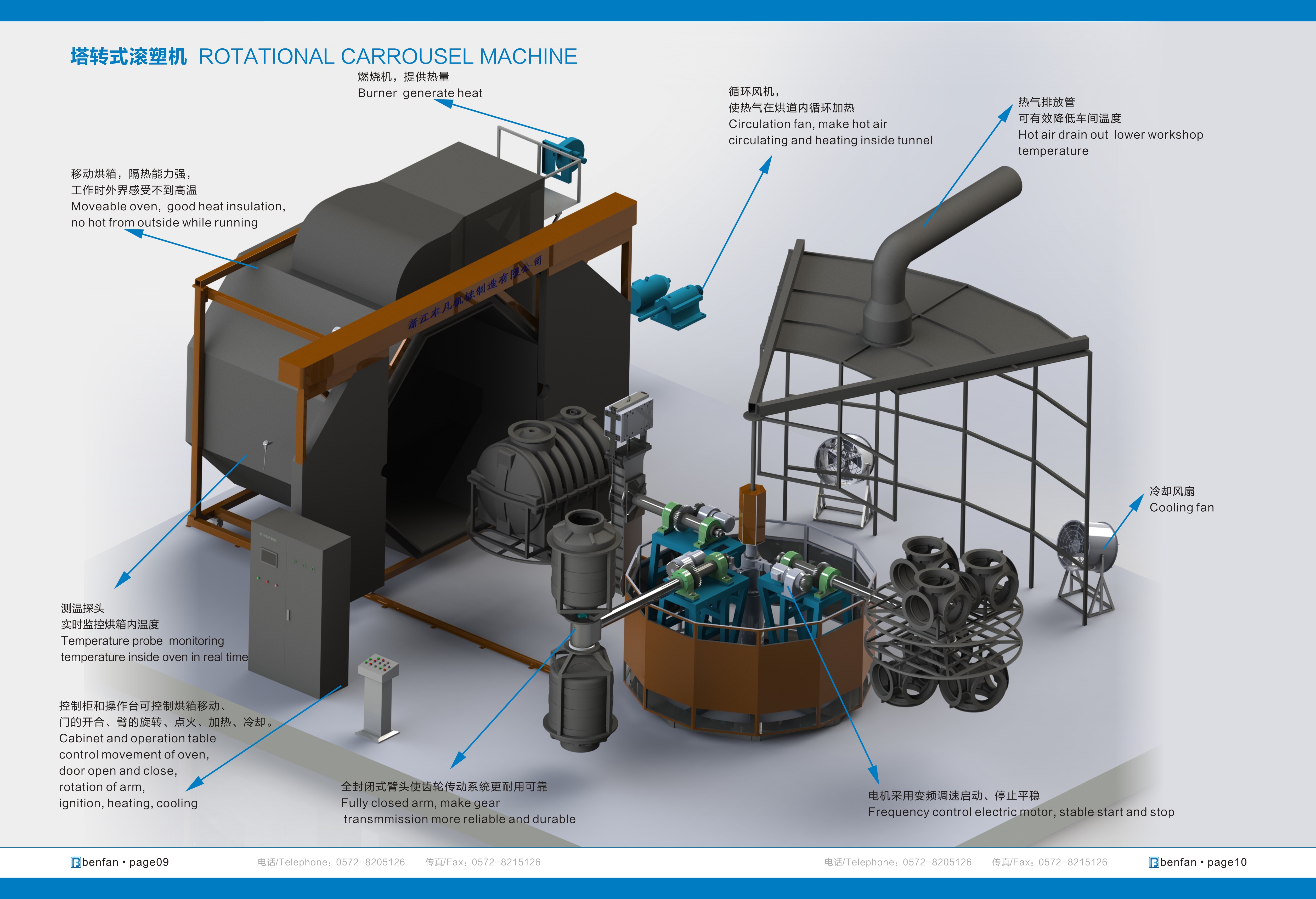

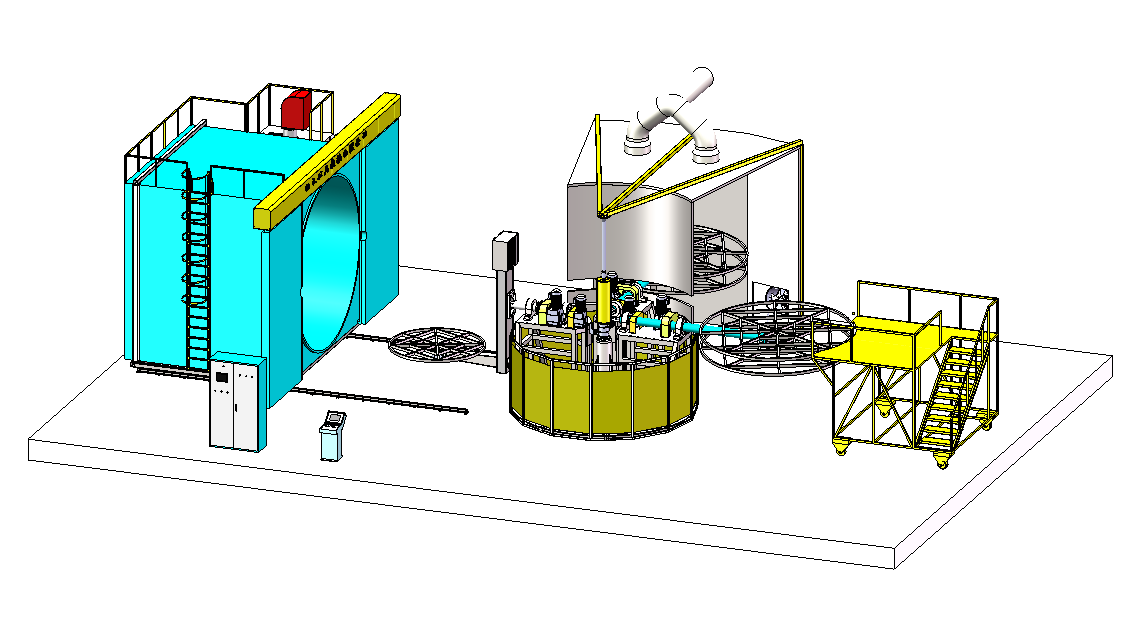

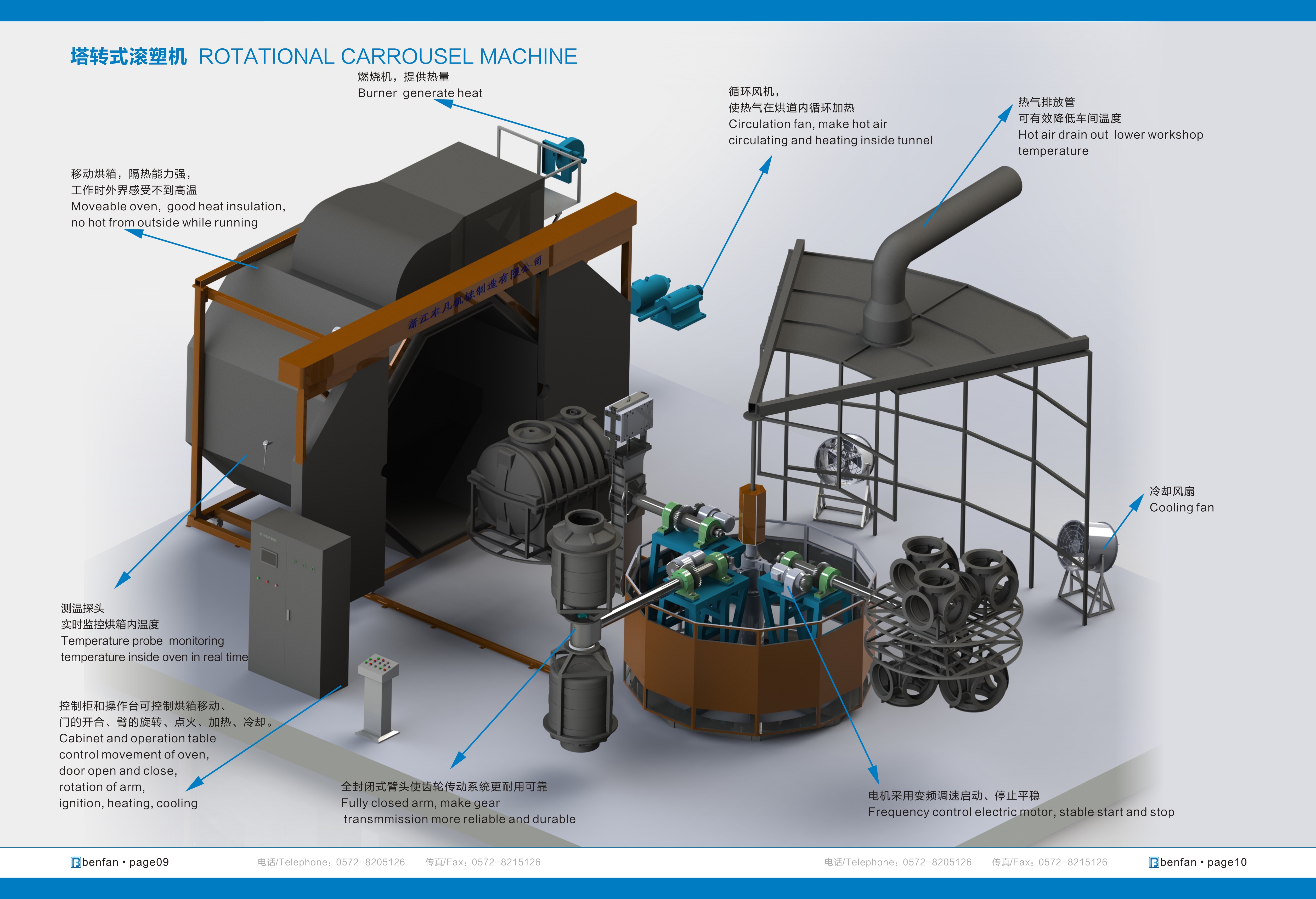

Advantages of carrousel rotational molding machine:

1. Efficiently produce high volumes with three workstations that heat, cool, and disassemble molds.

2. Ideal for products with comparable production times or large-scale production of identical items.

3. Includes a standalone cooling station, available with or without a cooling chamber.

Characteristics of carousel rotomolding machine

The tower type rotary molding machine is recognized by customers for its continuous production and high stability.

The three-arm turret type rotary molding machine is equipped with a central turret, paired with 3 mobile cars. According to different product requirements, it can choose from 4 stations (heating, cooling, mold disassembly, preparation) and 5 stations (heating, pre-cooling, cooling, mold disassembly, preparation).

The four arm turret rotary molding machine is equipped with a central turret, paired with four mobile cars. According to different product requirements, it can choose from 5 stations (heating, cooling, mold

disassembly, mold installation, preparation) and 6 stations (heating, pre-cooling, cooling, mold disassembly, mold installation, preparation).

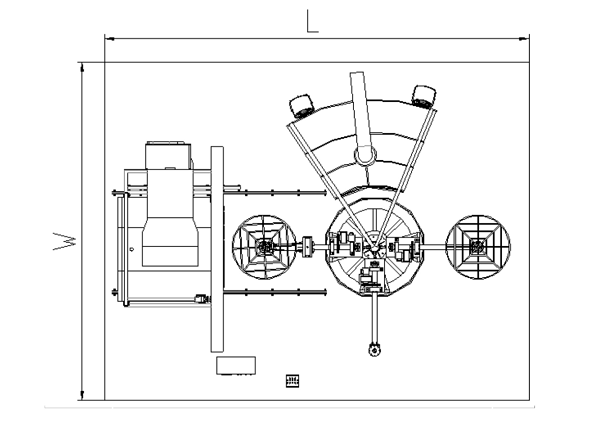

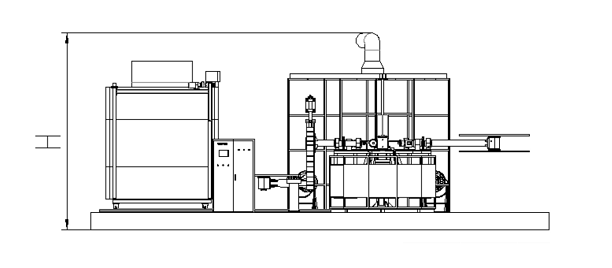

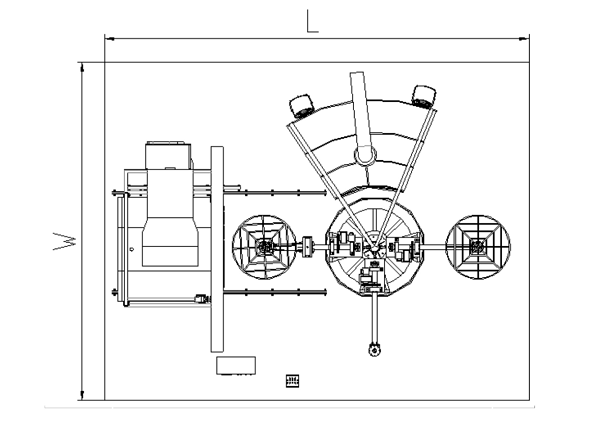

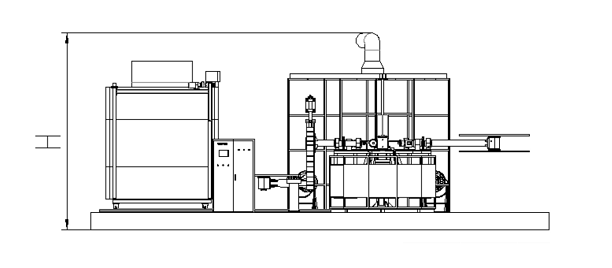

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

To find a qualified rotomolding machine supplier, consider the following steps:

1. Research and Gather Information: Start by conducting thorough research on rotomolding machine suppliers. Look for reputable manufacturers or suppliers with a proven track record in the industry. Read reviews, testimonials, and case studies to gather information about their reputation, product quality, and customer satisfaction.

2. Define Your Requirements: Clearly define your specific requirements for the rotomolding machine, including production capacity, size, automation level, and any specific features or customization needed. This will help you narrow down your search and find suppliers that can meet your specific needs.

3. Seek Recommendations: Ask for recommendations from industry peers, colleagues, or trade associations. They may have firsthand experience or knowledge of reliable rotomolding machine suppliers. Their recommendations can help you identify potential suppliers to consider.

4. Attend Trade Shows and Exhibitions: Attend industry trade shows, exhibitions, and conferences related to rotomolding. These events provide an opportunity to meet and interact with various suppliers, see their machines in action, and gather information about their capabilities and offerings.

5. Request Quotations and Proposals: Contact multiple rotomolding machine suppliers and request detailed quotations and proposals. Provide them with your specific requirements and ask for information on their machine specifications, technical support, warranty, and after-sales service. Compare the offerings and evaluate them based on your needs and budget.

6. Evaluate Supplier's Experience and Expertise: Assess the supplier's experience and expertise in the rotomolding industry. Consider factors such as the number of years in business, their client portfolio, and their knowledge of the rotomolding process. A supplier with extensive experience and expertise is more likely to provide reliable machines and support.

7. Visit Supplier's Facilities: If possible, visit the supplier's facilities to see their manufacturing process, quality control measures, and overall operations. This will give you a better understanding of their capabilities, production standards, and commitment to quality.

8. Check Certifications and Compliance: Ensure that the supplier meets industry standards and certifications. Look for certifications such as ISO 9001 for quality management systems and CE certification for compliance with European safety standards. These certifications indicate that the supplier follows established quality and safety practices.

9. Request References: Ask the supplier for references from their existing customers. Contact these references to gather feedback on the supplier's performance, machine reliability, and customer service. This will provide insights into the supplier's reputation and customer satisfaction.

10. Consider After-Sales Support: Evaluate the supplier's after-sales support and service capabilities. A reliable supplier should offer technical support, spare parts availability, and prompt assistance in case of any issues or maintenance needs.

By following these steps and conducting thorough due diligence, you can find a qualified rotomolding machine supplier that meets your specific requirements and provides reliable machines and support.

Advantages of carrousel rotational molding machine:

1. Efficiently produce high volumes with three workstations that heat, cool, and disassemble molds.

2. Ideal for products with comparable production times or large-scale production of identical items.

3. Includes a standalone cooling station, available with or without a cooling chamber.

Characteristics of carousel rotomolding machine

The tower type rotary molding machine is recognized by customers for its continuous production and high stability.

The three-arm turret type rotary molding machine is equipped with a central turret, paired with 3 mobile cars. According to different product requirements, it can choose from 4 stations (heating, cooling, mold disassembly, preparation) and 5 stations (heating, pre-cooling, cooling, mold disassembly, preparation).

The four arm turret rotary molding machine is equipped with a central turret, paired with four mobile cars. According to different product requirements, it can choose from 5 stations (heating, cooling, mold

disassembly, mold installation, preparation) and 6 stations (heating, pre-cooling, cooling, mold disassembly, mold installation, preparation).

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

To find a qualified rotomolding machine supplier, consider the following steps:

1. Research and Gather Information: Start by conducting thorough research on rotomolding machine suppliers. Look for reputable manufacturers or suppliers with a proven track record in the industry. Read reviews, testimonials, and case studies to gather information about their reputation, product quality, and customer satisfaction.

2. Define Your Requirements: Clearly define your specific requirements for the rotomolding machine, including production capacity, size, automation level, and any specific features or customization needed. This will help you narrow down your search and find suppliers that can meet your specific needs.

3. Seek Recommendations: Ask for recommendations from industry peers, colleagues, or trade associations. They may have firsthand experience or knowledge of reliable rotomolding machine suppliers. Their recommendations can help you identify potential suppliers to consider.

4. Attend Trade Shows and Exhibitions: Attend industry trade shows, exhibitions, and conferences related to rotomolding. These events provide an opportunity to meet and interact with various suppliers, see their machines in action, and gather information about their capabilities and offerings.

5. Request Quotations and Proposals: Contact multiple rotomolding machine suppliers and request detailed quotations and proposals. Provide them with your specific requirements and ask for information on their machine specifications, technical support, warranty, and after-sales service. Compare the offerings and evaluate them based on your needs and budget.

6. Evaluate Supplier's Experience and Expertise: Assess the supplier's experience and expertise in the rotomolding industry. Consider factors such as the number of years in business, their client portfolio, and their knowledge of the rotomolding process. A supplier with extensive experience and expertise is more likely to provide reliable machines and support.

7. Visit Supplier's Facilities: If possible, visit the supplier's facilities to see their manufacturing process, quality control measures, and overall operations. This will give you a better understanding of their capabilities, production standards, and commitment to quality.

8. Check Certifications and Compliance: Ensure that the supplier meets industry standards and certifications. Look for certifications such as ISO 9001 for quality management systems and CE certification for compliance with European safety standards. These certifications indicate that the supplier follows established quality and safety practices.

9. Request References: Ask the supplier for references from their existing customers. Contact these references to gather feedback on the supplier's performance, machine reliability, and customer service. This will provide insights into the supplier's reputation and customer satisfaction.

10. Consider After-Sales Support: Evaluate the supplier's after-sales support and service capabilities. A reliable supplier should offer technical support, spare parts availability, and prompt assistance in case of any issues or maintenance needs.

By following these steps and conducting thorough due diligence, you can find a qualified rotomolding machine supplier that meets your specific requirements and provides reliable machines and support.