- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-4000TL

SNOWBALL

8477.4010.00

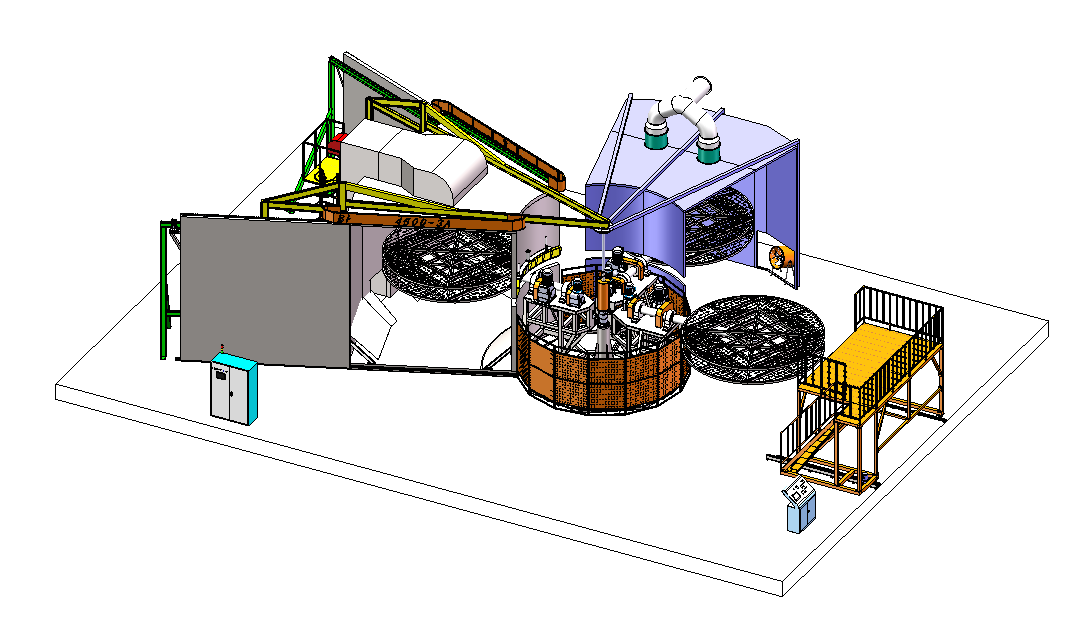

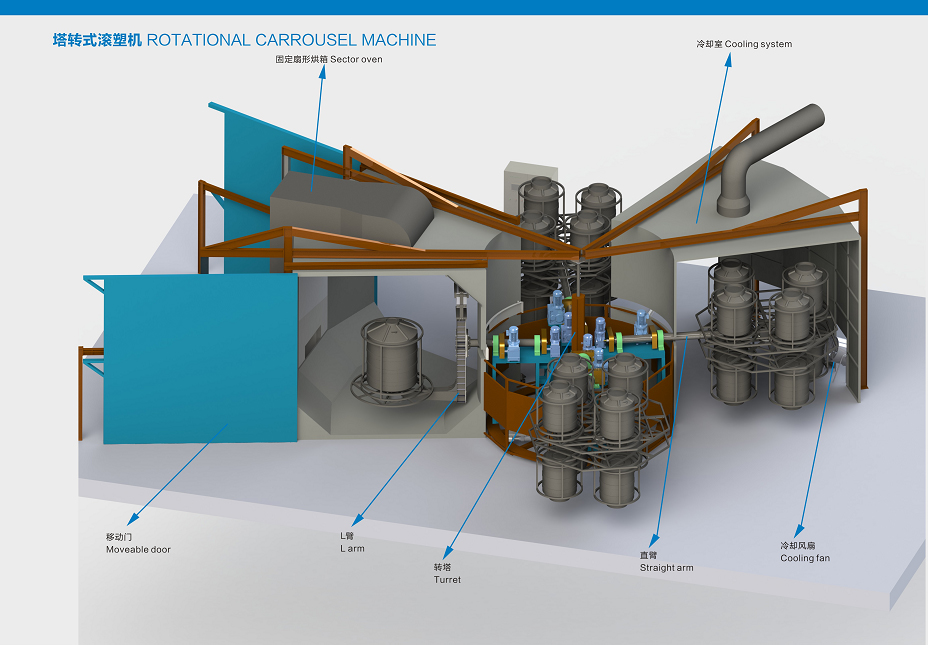

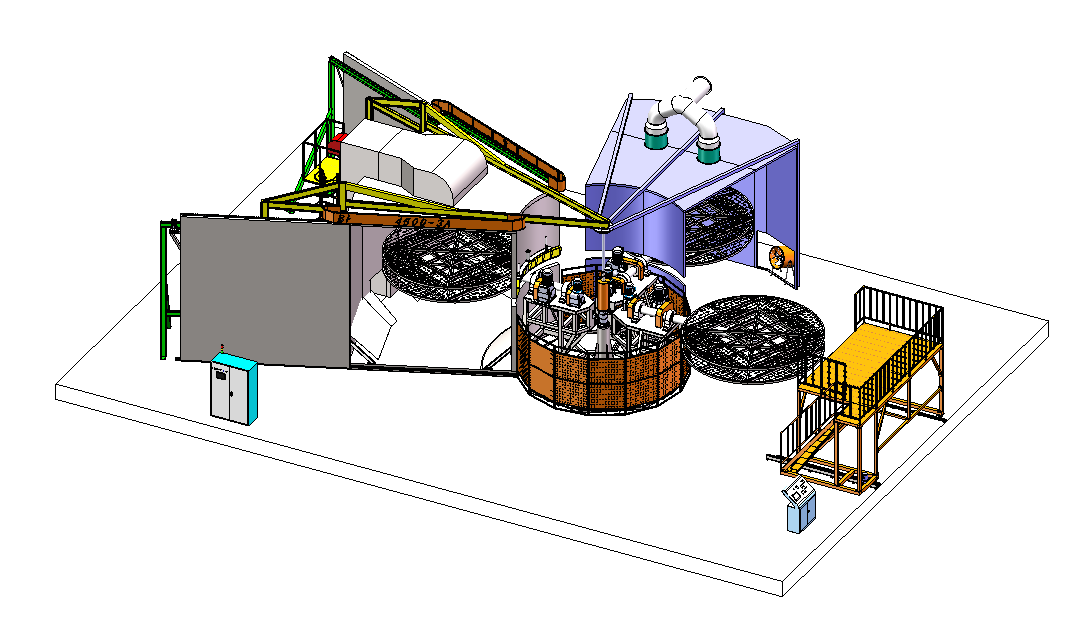

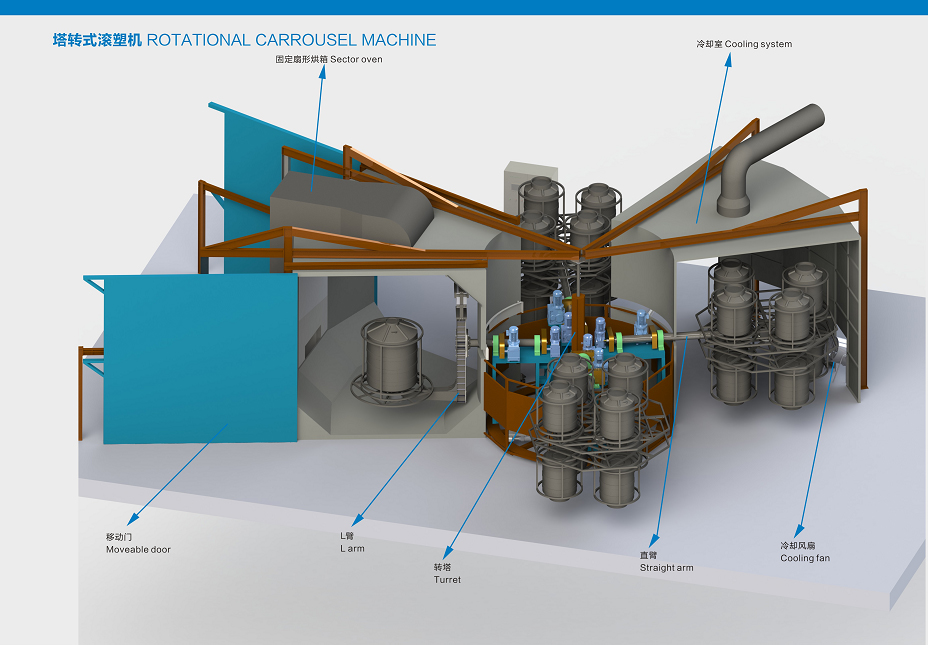

In contrast to traditional production, its operation is stable in the preferred sequence of customers.

Three Arm Turret Type: Three-arm turret rotational molding machine, three mobile cars, and one central turret. This will vary and will depend on product heat requirements can have four or five stations (Heating, Precooling, Cooling, Mold’s Demolding, Preparation) or (Heating, Cooling, Precooling, Mold’s Demolding, Preparation).

A four-arm turret rotary molding machine according to the present invention includes a central turret in conjunction with four mobile cars, wherein the choice is between 5 stations (heating, cooling, mold disassembly, mold installation, and preparation) and 6 stations (heating, pre-cooling, cooling, mold disassembly, mold installation, and preparation) depending on the requirements of the product.

High Stability: Ensures consistent and reliable performance in continuous production.

Flexible Station Options: Configurable with 4-6 stations to meet diverse production needs.

Advanced Control System: Siemens PLC enables precise adjustment of speed, temperature, and timing.

Customizable Design: Supports three-arm and four-arm configurations with tailored setups.

Optimized Efficiency: Designed to enhance productivity and adapt to various applications.

Control System for equipment using Siemens PLC. Programming is possible wiring is as follows:

The major (shaft) axis speed of each arm can be adjusted between 1-12 RPM.

The minor (disk) axis speed of each arm is adjustable within a range of 1-16 RPM.

Each arm allows precise control of maximum and minimum temperatures.

Heating times for each arm are customizable and can be controlled individually.

Cooling times for each arm at the cooling station can be individually customized.

Mold inflation time is fully adjustable and can be set independently for each arm.

| Category | Details |

|---|---|

| Product Name | Three or four arms Carrousel Rotational Molding Machine |

| Brand | SNOWBALL ROTO |

| Origin | China |

| Machinery type | Carrousel rotomolding machine |

| Heating supply | Natural gas, liquefied gas, diesel oil |

| Temperature control | DTE Control ±2°C |

| Burner system | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

| Cooling mode | Fan cooling or water cooling |

| Control mode | Touch screen + PLC (Siemens brand) |

| Electric brand | Schneider, Omron |

| Delivery time | About 60 days after receiving the deposit |

| Overseas Installation period | It depends on machine size, usually takes 10-20 days |

| Heating rate | 3 minutes from room temperature to 280°C in oven |

| Core components | Engine, PLC, Motor |

| Voltage | 380V |

| Power | 55kw |

| Materials | PE, PP, PVC |

| Function | Manufacture hollow plastic products |

| Control | Touchscreen control |

Technical data sheet:

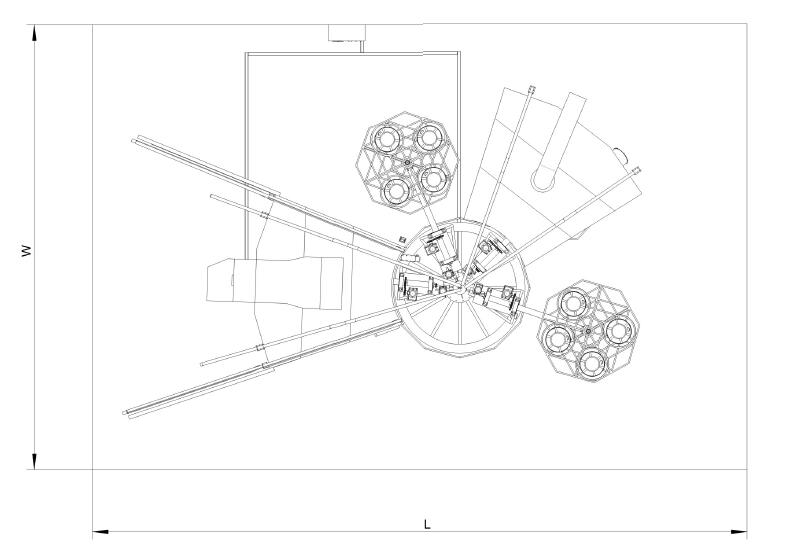

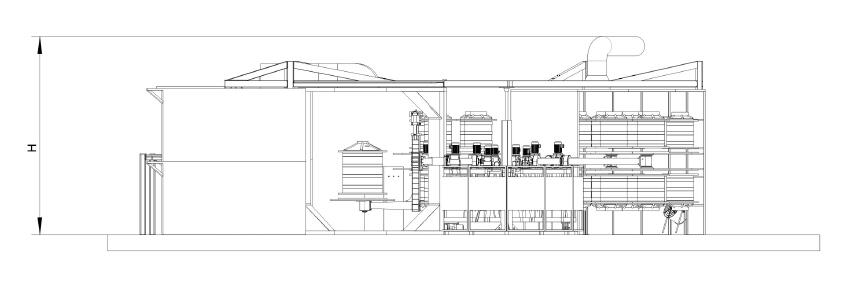

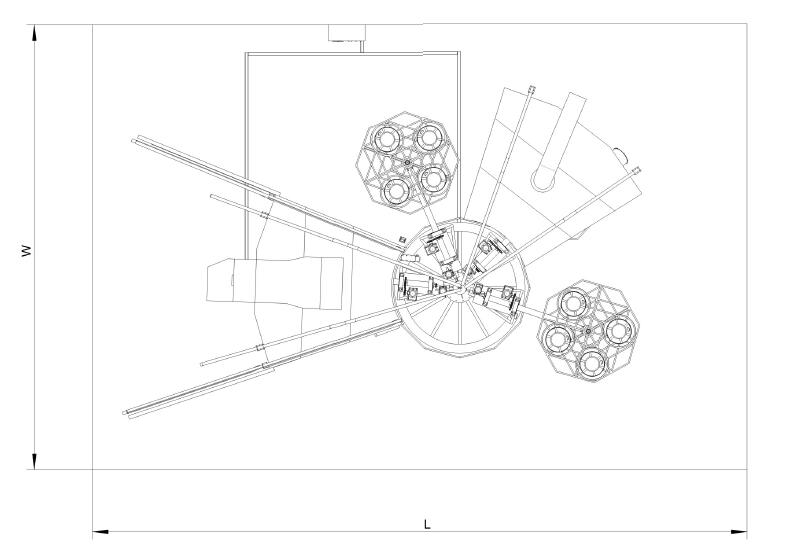

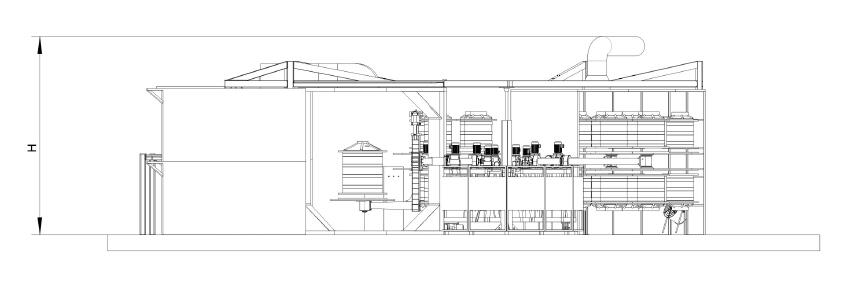

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

CE Certificate:

FAQ:

Q1. What are your company's main products?

A: We primarily produce rotational molding machines, molds, and cooler boxes.

Q2. What is the MOQ for your products?

A: For rotomolded coolers, the MOQ is 50 pieces. Samples are available; you only need to cover the sample cost and courier fee. The sample cost will be refunded when you place an order.

Q3. What are your payment terms?

A:For machines and molds: A 50% deposit via TT is required upon signing the contract, with the remaining 50% due after inspection and before shipment.

For cooler boxes: A 30% deposit via TT is required, with the balance payable upon receiving the Bill of Lading copy.

Q4. What is your delivery time?

A:For machines: Typically within 60 working days after receiving the deposit.

For cooler boxes: Within 20-30 working days for a 40HQ container after receiving the deposit.

Q5. How do you handle transportation?

A: We ship by sea or air from Shanghai or Ningbo ports.

Q6. What after-sales services do you provide?

A:Machine Warranty: One-year warranty after installation and trial adjustment at the customer's workshop. We will send two engineers to assist with assembly and trial runs.

Cooler Box Warranty: If any issues arise, we will provide a replacement in your next order.

Q7. Are all goods tested before delivery?

A: Yes, 100% of our machines are tested by our engineers before leaving the factory.

In contrast to traditional production, its operation is stable in the preferred sequence of customers.

Three Arm Turret Type: Three-arm turret rotational molding machine, three mobile cars, and one central turret. This will vary and will depend on product heat requirements can have four or five stations (Heating, Precooling, Cooling, Mold’s Demolding, Preparation) or (Heating, Cooling, Precooling, Mold’s Demolding, Preparation).

A four-arm turret rotary molding machine according to the present invention includes a central turret in conjunction with four mobile cars, wherein the choice is between 5 stations (heating, cooling, mold disassembly, mold installation, and preparation) and 6 stations (heating, pre-cooling, cooling, mold disassembly, mold installation, and preparation) depending on the requirements of the product.

High Stability: Ensures consistent and reliable performance in continuous production.

Flexible Station Options: Configurable with 4-6 stations to meet diverse production needs.

Advanced Control System: Siemens PLC enables precise adjustment of speed, temperature, and timing.

Customizable Design: Supports three-arm and four-arm configurations with tailored setups.

Optimized Efficiency: Designed to enhance productivity and adapt to various applications.

Control System for equipment using Siemens PLC. Programming is possible wiring is as follows:

The major (shaft) axis speed of each arm can be adjusted between 1-12 RPM.

The minor (disk) axis speed of each arm is adjustable within a range of 1-16 RPM.

Each arm allows precise control of maximum and minimum temperatures.

Heating times for each arm are customizable and can be controlled individually.

Cooling times for each arm at the cooling station can be individually customized.

Mold inflation time is fully adjustable and can be set independently for each arm.

| Category | Details |

|---|---|

| Product Name | Three or four arms Carrousel Rotational Molding Machine |

| Brand | SNOWBALL ROTO |

| Origin | China |

| Machinery type | Carrousel rotomolding machine |

| Heating supply | Natural gas, liquefied gas, diesel oil |

| Temperature control | DTE Control ±2°C |

| Burner system | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

| Cooling mode | Fan cooling or water cooling |

| Control mode | Touch screen + PLC (Siemens brand) |

| Electric brand | Schneider, Omron |

| Delivery time | About 60 days after receiving the deposit |

| Overseas Installation period | It depends on machine size, usually takes 10-20 days |

| Heating rate | 3 minutes from room temperature to 280°C in oven |

| Core components | Engine, PLC, Motor |

| Voltage | 380V |

| Power | 55kw |

| Materials | PE, PP, PVC |

| Function | Manufacture hollow plastic products |

| Control | Touchscreen control |

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

CE Certificate:

FAQ:

Q1. What are your company's main products?

A: We primarily produce rotational molding machines, molds, and cooler boxes.

Q2. What is the MOQ for your products?

A: For rotomolded coolers, the MOQ is 50 pieces. Samples are available; you only need to cover the sample cost and courier fee. The sample cost will be refunded when you place an order.

Q3. What are your payment terms?

A:For machines and molds: A 50% deposit via TT is required upon signing the contract, with the remaining 50% due after inspection and before shipment.

For cooler boxes: A 30% deposit via TT is required, with the balance payable upon receiving the Bill of Lading copy.

Q4. What is your delivery time?

A:For machines: Typically within 60 working days after receiving the deposit.

For cooler boxes: Within 20-30 working days for a 40HQ container after receiving the deposit.

Q5. How do you handle transportation?

A: We ship by sea or air from Shanghai or Ningbo ports.

Q6. What after-sales services do you provide?

A:Machine Warranty: One-year warranty after installation and trial adjustment at the customer's workshop. We will send two engineers to assist with assembly and trial runs.

Cooler Box Warranty: If any issues arise, we will provide a replacement in your next order.

Q7. Are all goods tested before delivery?

A: Yes, 100% of our machines are tested by our engineers before leaving the factory.