- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-4500TL

SNOWBALL

8477.4010.00

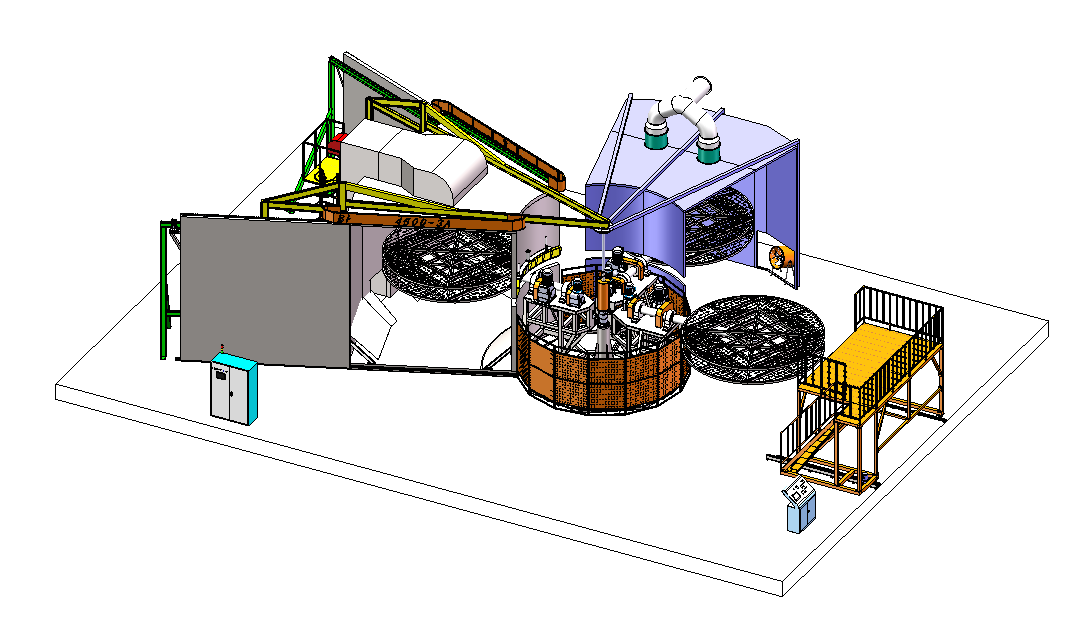

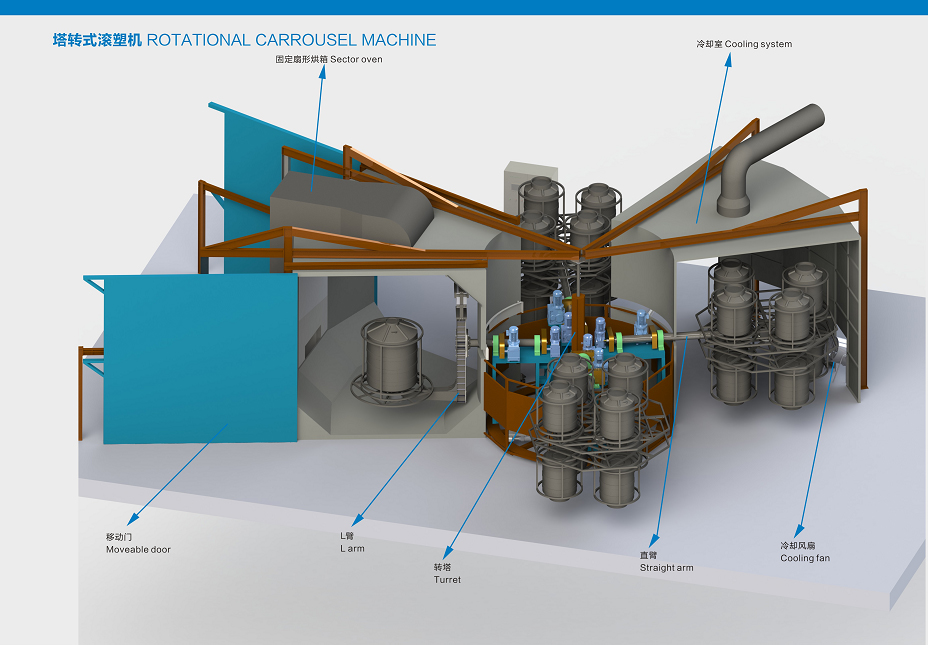

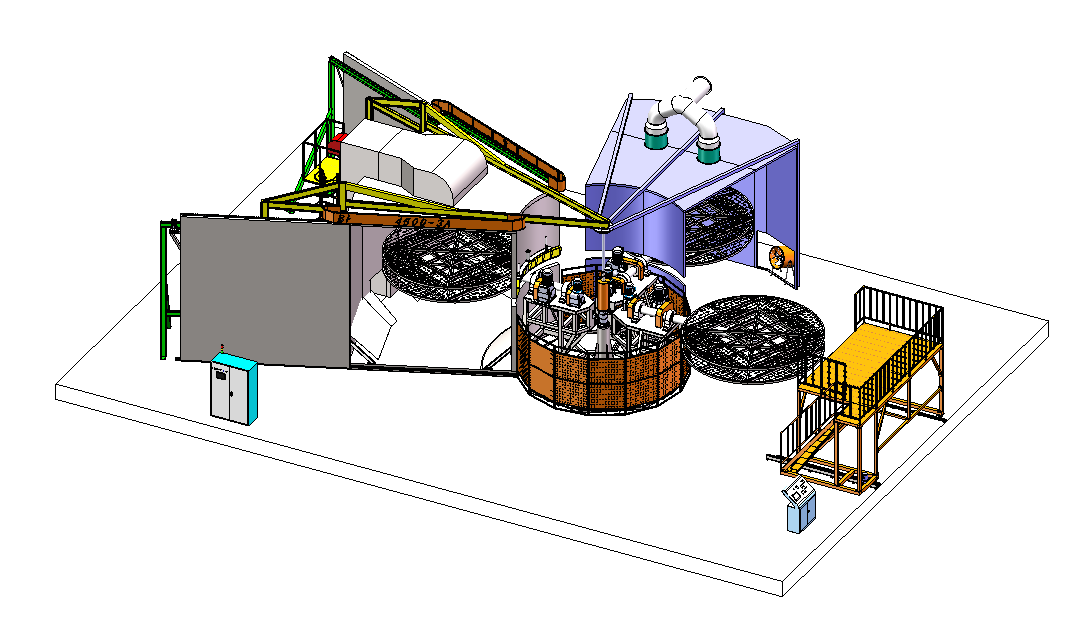

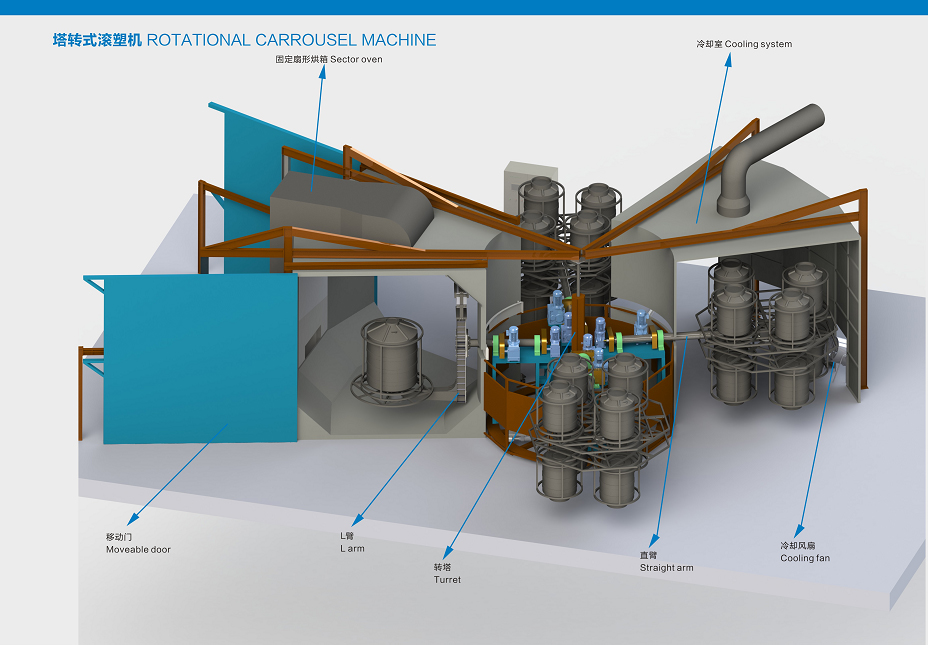

This carrousel machine is suitable for making relatively large products with different sizes but similar output. It can bear three or four arms and has three to four stations (heating, cooling, loading).It has two doors.The oven is fixed on the floor.

Technical data sheet:

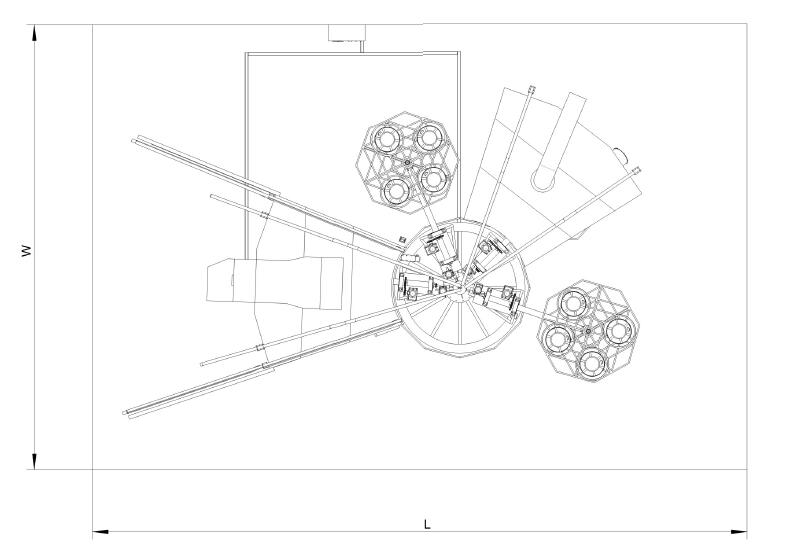

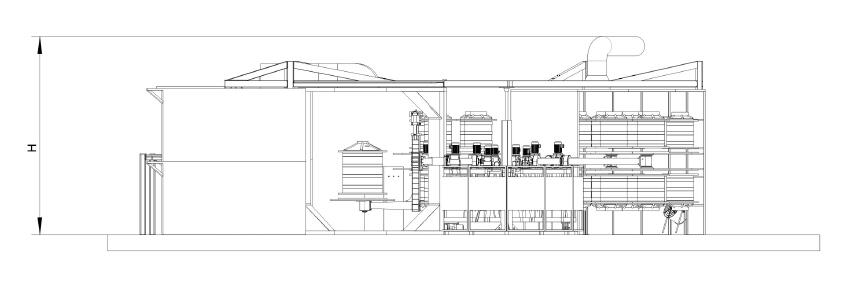

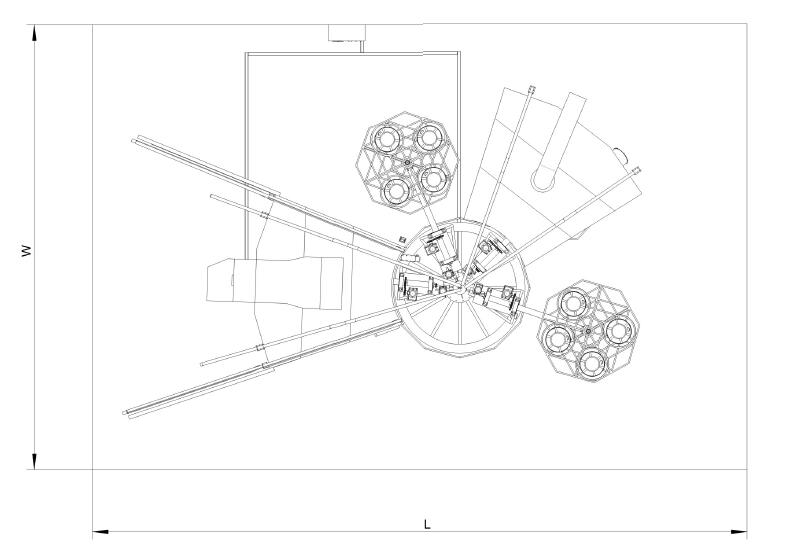

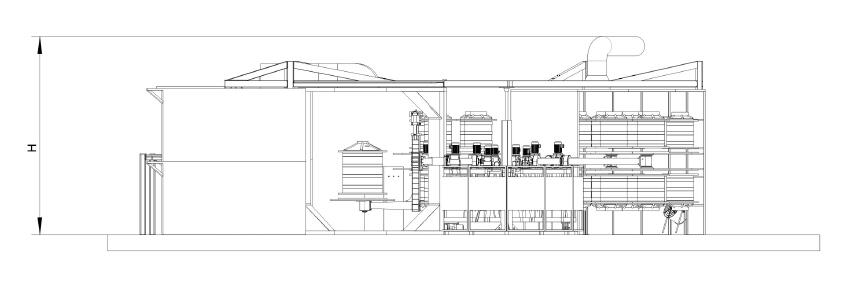

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

The equipment control system using Siemens PLC, programmable,

you can write as follows::

1, The speed of major (Shaft) axis of each arm (1-12 RPM).

2, The speed of auxiliary (Disk) axis of each arm(1-16 RPM).

3, The maximum temperature and minimum temperature of each arm.

4, The heating times of each arm.(customized, could be individual control )

5, The cooling times of each arm.(customize, could be individual control)

6, The Mold inflatable time(customized, could be individual control)

7, Showing the statement for each arm.(Help the labor to operate)

8, Show the heating temperature curve of the oven

(Good for adjust the product of temperature request )

9, Show the already heated time of oven

10, Show the cooling time of cooling station

11, Electricity balance meters are provided to indicate out-of -balance conditions on the arms

12、Siemens Frequency Changer(Invertor)including: 3 sets for major axis, 3 sets for auxiliary axis

13、The electrical components are using Schneider brand

Selecting the right rotomolding machine for your specific needs requires careful consideration of several factors.

Here are some steps to help you choose a suitable rotomolding machine:

1. Define your requirements: Determine your specific production requirements, including the size and complexity of the products you plan to manufacture, desired output capacity, and any special features or customization options you need. This will help you narrow down the options and find a machine that meets your specific needs.

2. Consider machine size and capacity: Evaluate the size and capacity of the rotomolding machine. Ensure that it can accommodate the size and quantity of products you intend to produce. Consider factors such as the oven size, mold capacity, and cooling system to ensure they align with your production requirements.

3. Assess machine features and capabilities: Review the features and capabilities of the rotomolding machine. Consider factors such as the number of arms, independent or simultaneous rotation, heating system efficiency, cooling system effectiveness, and control panel functionality. Ensure that the machine has the necessary features to produce the desired product quality and meet your production goals.

4. Evaluate machine construction and durability: Examine the construction and durability of the machine. Look for robust materials, such as stainless steel or high-quality alloys, that offer longevity and resistance to corrosion. Consider the overall build quality, including the welding, connections, and reinforcement, to ensure the machine can withstand the rigors of continuous operation.

5. Check energy efficiency: Assess the energy efficiency of the rotomolding machine. Look for features such as insulation, energy-saving heating systems, and efficient cooling methods. An energy-efficient machine can help reduce operating costs and minimize environmental impact.

6. Consider automation and control: Evaluate the level of automation and control offered by the machine. Look for features such as programmable logic controllers (PLCs), touchscreen interfaces, and automation options for improved efficiency and ease of operation. Automation can streamline the production process and enhance productivity.

7. Assess supplier reputation and support: Research the reputation and reliability of the machine supplier. Look for customer reviews, testimonials, and feedback to gauge their track record. Consider their after-sales support, including technical assistance, spare parts availability, and maintenance services. A reputable supplier with good support can ensure a smooth and efficient operation of the machine.

8. Budget considerations: Consider your budget and ensure that the selected rotomolding machine falls within your financial constraints. Evaluate the initial purchase cost, ongoing maintenance expenses, and any additional equipment or accessories required.

By carefully considering these factors and aligning them with your specific requirements and budget, you can select a suitable rotomolding machine that meets your production needs and contributes to the success of your manufacturing process.

Welcome to enquiry and send us your requirement!

This carrousel machine is suitable for making relatively large products with different sizes but similar output. It can bear three or four arms and has three to four stations (heating, cooling, loading).It has two doors.The oven is fixed on the floor.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500TL | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000TL | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500TL | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000TL | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500TL | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

The equipment control system using Siemens PLC, programmable,

you can write as follows::

1, The speed of major (Shaft) axis of each arm (1-12 RPM).

2, The speed of auxiliary (Disk) axis of each arm(1-16 RPM).

3, The maximum temperature and minimum temperature of each arm.

4, The heating times of each arm.(customized, could be individual control )

5, The cooling times of each arm.(customize, could be individual control)

6, The Mold inflatable time(customized, could be individual control)

7, Showing the statement for each arm.(Help the labor to operate)

8, Show the heating temperature curve of the oven

(Good for adjust the product of temperature request )

9, Show the already heated time of oven

10, Show the cooling time of cooling station

11, Electricity balance meters are provided to indicate out-of -balance conditions on the arms

12、Siemens Frequency Changer(Invertor)including: 3 sets for major axis, 3 sets for auxiliary axis

13、The electrical components are using Schneider brand

Selecting the right rotomolding machine for your specific needs requires careful consideration of several factors.

Here are some steps to help you choose a suitable rotomolding machine:

1. Define your requirements: Determine your specific production requirements, including the size and complexity of the products you plan to manufacture, desired output capacity, and any special features or customization options you need. This will help you narrow down the options and find a machine that meets your specific needs.

2. Consider machine size and capacity: Evaluate the size and capacity of the rotomolding machine. Ensure that it can accommodate the size and quantity of products you intend to produce. Consider factors such as the oven size, mold capacity, and cooling system to ensure they align with your production requirements.

3. Assess machine features and capabilities: Review the features and capabilities of the rotomolding machine. Consider factors such as the number of arms, independent or simultaneous rotation, heating system efficiency, cooling system effectiveness, and control panel functionality. Ensure that the machine has the necessary features to produce the desired product quality and meet your production goals.

4. Evaluate machine construction and durability: Examine the construction and durability of the machine. Look for robust materials, such as stainless steel or high-quality alloys, that offer longevity and resistance to corrosion. Consider the overall build quality, including the welding, connections, and reinforcement, to ensure the machine can withstand the rigors of continuous operation.

5. Check energy efficiency: Assess the energy efficiency of the rotomolding machine. Look for features such as insulation, energy-saving heating systems, and efficient cooling methods. An energy-efficient machine can help reduce operating costs and minimize environmental impact.

6. Consider automation and control: Evaluate the level of automation and control offered by the machine. Look for features such as programmable logic controllers (PLCs), touchscreen interfaces, and automation options for improved efficiency and ease of operation. Automation can streamline the production process and enhance productivity.

7. Assess supplier reputation and support: Research the reputation and reliability of the machine supplier. Look for customer reviews, testimonials, and feedback to gauge their track record. Consider their after-sales support, including technical assistance, spare parts availability, and maintenance services. A reputable supplier with good support can ensure a smooth and efficient operation of the machine.

8. Budget considerations: Consider your budget and ensure that the selected rotomolding machine falls within your financial constraints. Evaluate the initial purchase cost, ongoing maintenance expenses, and any additional equipment or accessories required.

By carefully considering these factors and aligning them with your specific requirements and budget, you can select a suitable rotomolding machine that meets your production needs and contributes to the success of your manufacturing process.

Welcome to enquiry and send us your requirement!