- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

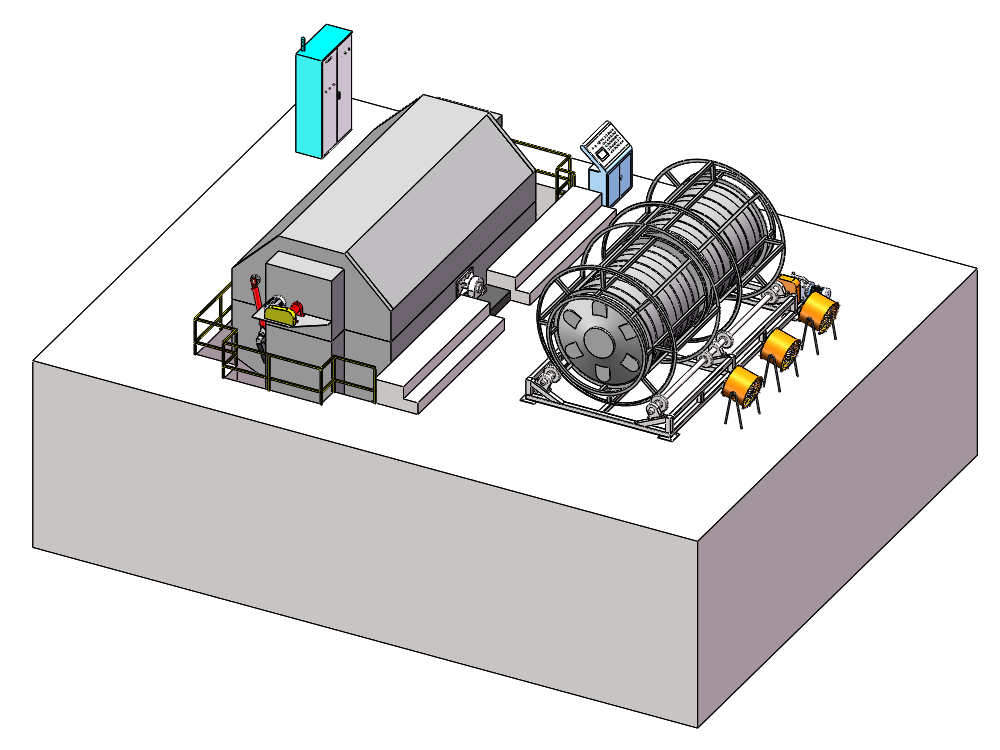

5000-Rock&Roll

SNOWBALL

8477.4010.00

This rock and roll equipment is ideal for making lengthy and slender molds such as kayaks and boats. It conserves energy, is user-friendly, and can be operated through a touch screen with complete automation.

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

1. Efficient production process: Rock and roll machines offer a relatively fast production process. The rocking motion allows for quicker and more efficient melting, coating, and cooling of the plastic material, reducing cycle times and increasing production output.

2. Cost-effective production: The reduced material waste, faster cycle times, and increased production output of rock and roll machines contribute to cost-effective production. Manufacturers can optimize their resources and achieve higher productivity, leading to improved profitability.

3. Customization options: Rock and roll machines offer flexibility in terms of mold design and customization. They can accommodate various mold sizes and shapes, allowing manufacturers to produce unique and tailored products according to specific customer requirements.

4. Easy operation and maintenance: Rock and roll machines are generally user-friendly and easy to operate. They require minimal maintenance and have fewer moving parts compared to other types of rotomolding machines, resulting in lower maintenance costs and downtime.

Welcome to enquiry us! Rotate your business,Snowball your wealth!

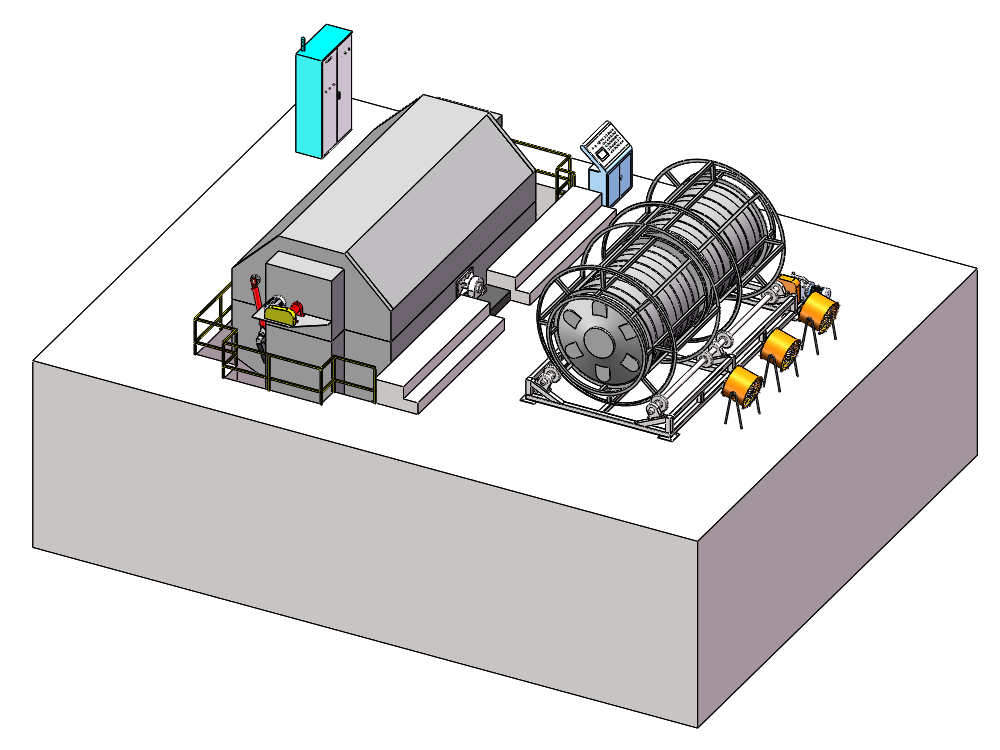

This rock and roll equipment is ideal for making lengthy and slender molds such as kayaks and boats. It conserves energy, is user-friendly, and can be operated through a touch screen with complete automation.

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

1. Efficient production process: Rock and roll machines offer a relatively fast production process. The rocking motion allows for quicker and more efficient melting, coating, and cooling of the plastic material, reducing cycle times and increasing production output.

2. Cost-effective production: The reduced material waste, faster cycle times, and increased production output of rock and roll machines contribute to cost-effective production. Manufacturers can optimize their resources and achieve higher productivity, leading to improved profitability.

3. Customization options: Rock and roll machines offer flexibility in terms of mold design and customization. They can accommodate various mold sizes and shapes, allowing manufacturers to produce unique and tailored products according to specific customer requirements.

4. Easy operation and maintenance: Rock and roll machines are generally user-friendly and easy to operate. They require minimal maintenance and have fewer moving parts compared to other types of rotomolding machines, resulting in lower maintenance costs and downtime.

Welcome to enquiry us! Rotate your business,Snowball your wealth!