- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-3000CS

SNOWBALL

8477.4010.00

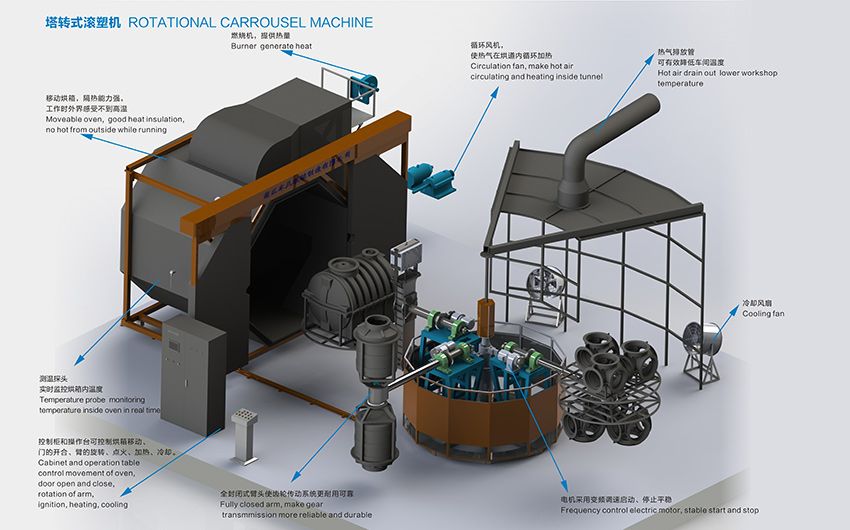

The carrousel rotomolding machine is a commonly used molding equipment. Each arm operates independently, with its own rotating speed, heating temperature, and cooling time. This machine is suitable for producing products with varying materials and thicknesses, making it flexible and highly efficient.

This carrousel rotomolding machine has a round shape and can be easily moved. It features a single door, which helps save energy and makes it popular among users. With either three or four arms, its output capacity can be increased by 30% compared to a shuttle rotomolding machine.

1. Heating, cooling, and disassembling molds, with three workstations for streamlined operation, resulting in high production.

2. Suitable for products with similar production times (heating+disassembling molds), or for mass production of the same products.

3.It has an independent cooling station (optional with or without a cooling chamber).

The tower type rotary molding machine is recognized by customers for its continuous production and high stability.

The three-arm turret type rotary molding machine is equipped with a central turret, paired with 3 mobile cars. According to different product requirements, it can choose from 4 stations (heating, cooling, mold disassembly, preparation) and 5 stations (heating, pre-cooling, cooling, mold disassembly, preparation).

The four arm turret rotary molding machine is equipped with a central turret, paired with four mobile cars. According to different product requirements, it can choose from 5 stations (heating, cooling, mold disassembly, mold installation, preparation) and 6 stations (heating, pre-cooling, cooling, mold disassembly, mold installation, preparation).

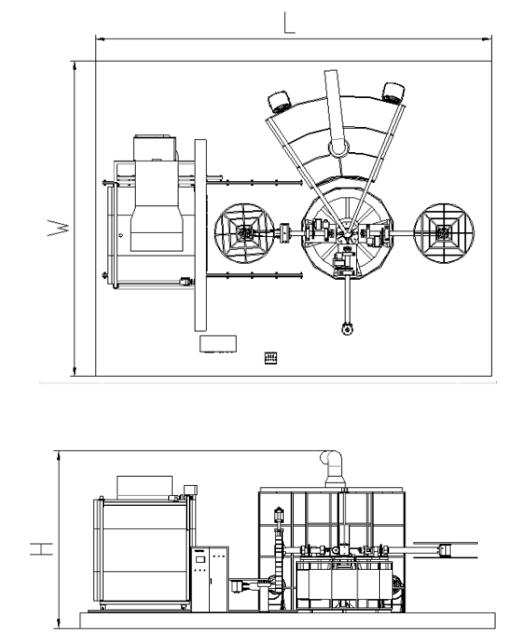

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 30 | 12 |

BF-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 16 |

BF-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 20 |

BF-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45 | 24 |

BF-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 45 | 26 |

BF-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 56 | 28 |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello |

Cooling mode: | Fan cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

1, Full gear transmission, without chain

2, Automatic locking device on the door.

3, Burner have safety protection system

4, With memory system for frequent production.

5, Customize of paint material (Friendly environment)

6, Heat insulation cotton(friendly environment)

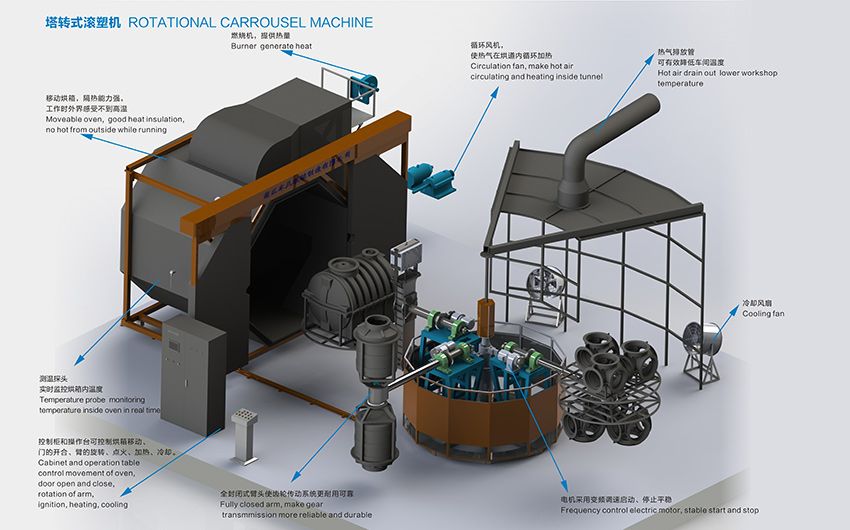

The carrousel rotomolding machine is a commonly used molding equipment. Each arm operates independently, with its own rotating speed, heating temperature, and cooling time. This machine is suitable for producing products with varying materials and thicknesses, making it flexible and highly efficient.

This carrousel rotomolding machine has a round shape and can be easily moved. It features a single door, which helps save energy and makes it popular among users. With either three or four arms, its output capacity can be increased by 30% compared to a shuttle rotomolding machine.

1. Heating, cooling, and disassembling molds, with three workstations for streamlined operation, resulting in high production.

2. Suitable for products with similar production times (heating+disassembling molds), or for mass production of the same products.

3.It has an independent cooling station (optional with or without a cooling chamber).

The tower type rotary molding machine is recognized by customers for its continuous production and high stability.

The three-arm turret type rotary molding machine is equipped with a central turret, paired with 3 mobile cars. According to different product requirements, it can choose from 4 stations (heating, cooling, mold disassembly, preparation) and 5 stations (heating, pre-cooling, cooling, mold disassembly, preparation).

The four arm turret rotary molding machine is equipped with a central turret, paired with four mobile cars. According to different product requirements, it can choose from 5 stations (heating, cooling, mold disassembly, mold installation, preparation) and 6 stations (heating, pre-cooling, cooling, mold disassembly, mold installation, preparation).

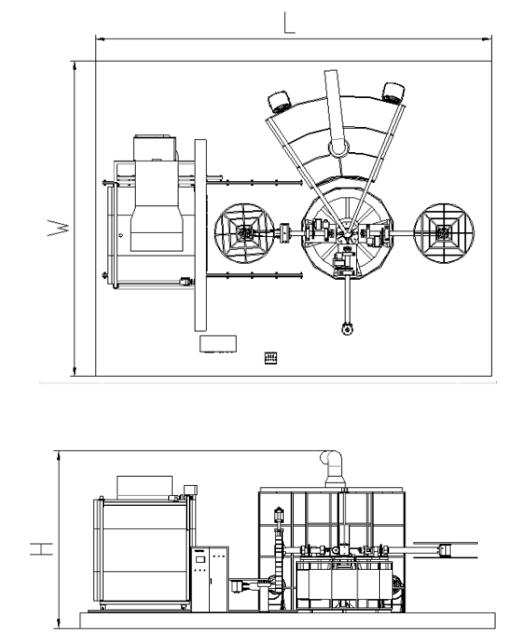

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 30 | 12 |

BF-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 16 |

BF-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 20 |

BF-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45 | 24 |

BF-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 45 | 26 |

BF-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 56 | 28 |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello |

Cooling mode: | Fan cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

1, Full gear transmission, without chain

2, Automatic locking device on the door.

3, Burner have safety protection system

4, With memory system for frequent production.

5, Customize of paint material (Friendly environment)

6, Heat insulation cotton(friendly environment)