- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-3000TL-4A

SNOWBALL

8477.4010.00

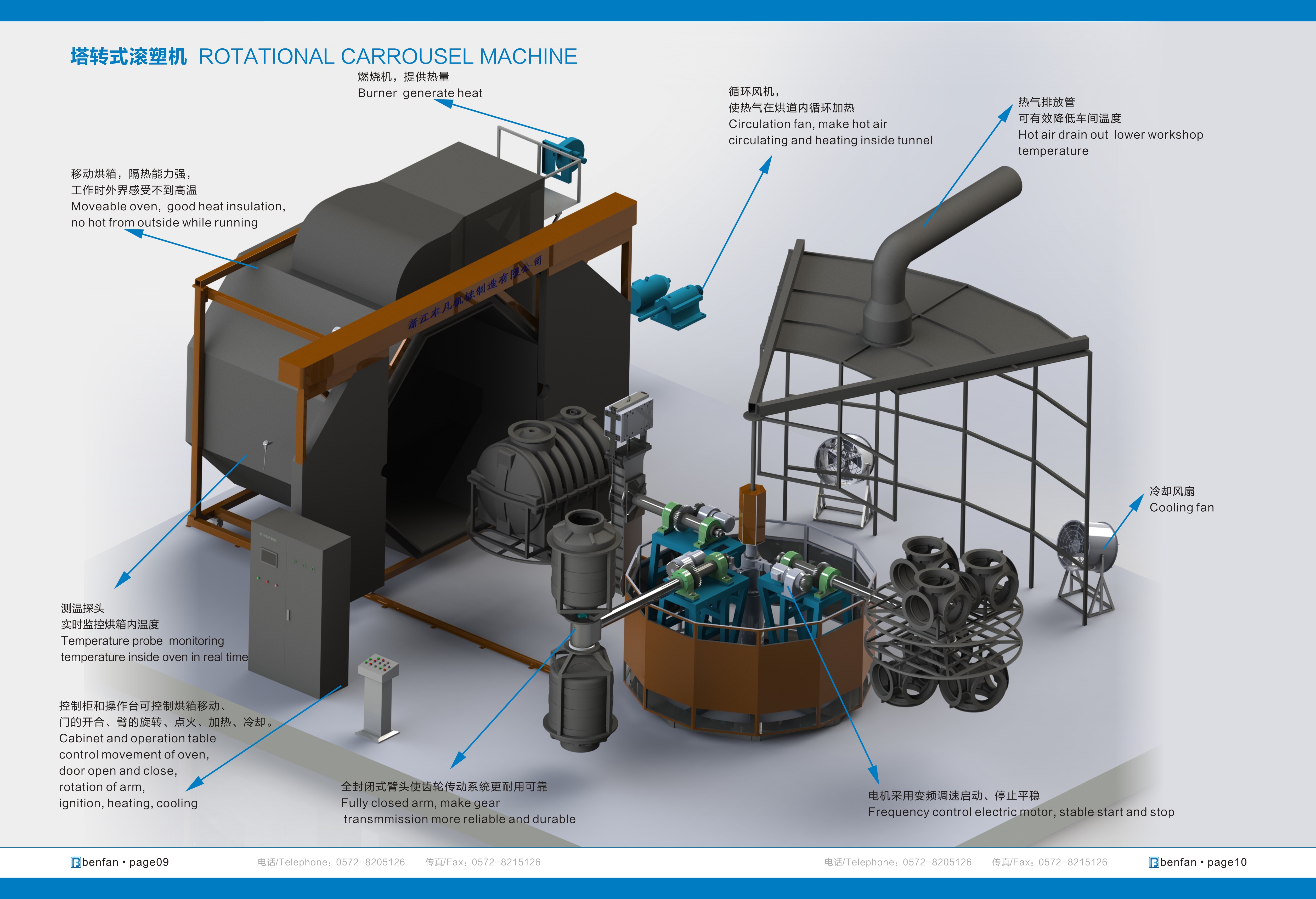

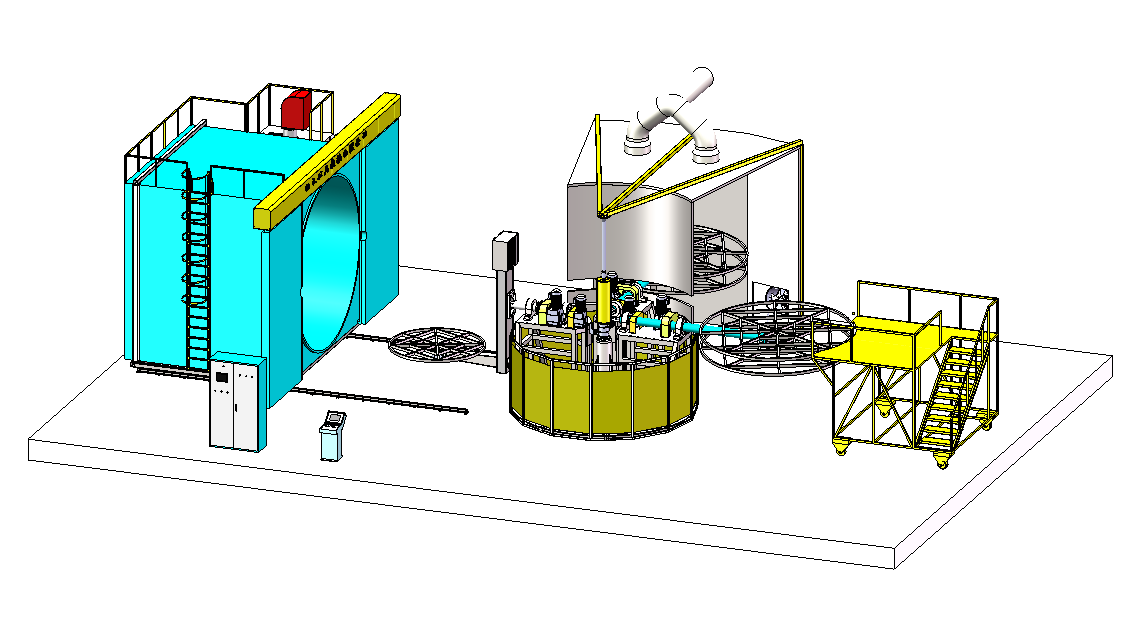

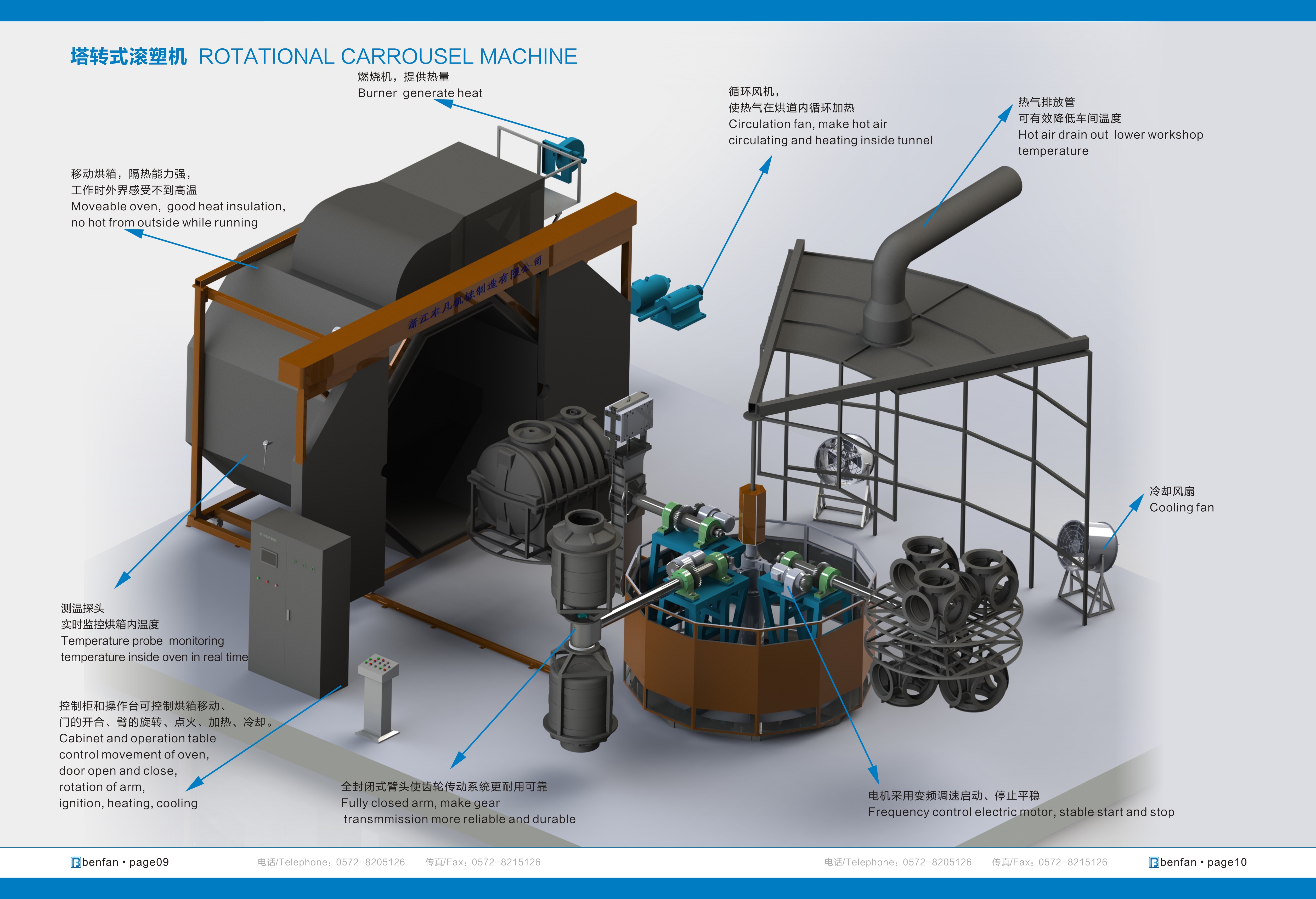

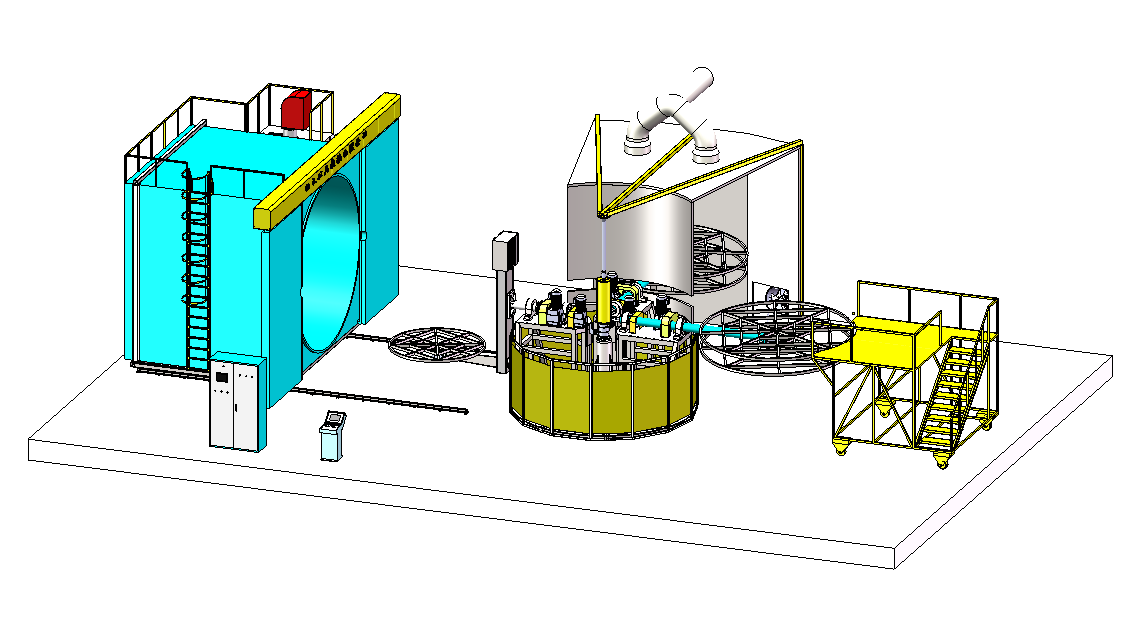

Carrousel rotational molding machine, its central tower bears the weight and the multi beams rotate synchronously. Its main characteristic is that it has relatively high reliability and practicability with simple and fast structure. It is good for producing relatively large products with different sizes but same of similar output frequency. It can bear three to four beams and three to four stations(heating, precooling, cooling and loading)

Characteristics of tower turning machine

Customers highly appreciate the tower type rotary molding machine for its exceptional stability and ability to produce continuously.

The three-arm turret type rotary molding machine boasts a central turret and three mobile cars, allowing for flexibility in choosing between four or five stations (heating, cooling, mold disassembly, preparation, and pre-cooling) based on the specific product requirements.

The four-arm turret rotary molding machine comes equipped with a central turret and four mobile cars, providing even more options for station selection. Depending on the product needs, users can choose from five or six stations (heating, cooling, mold disassembly, mold installation, preparation, and pre-cooling).

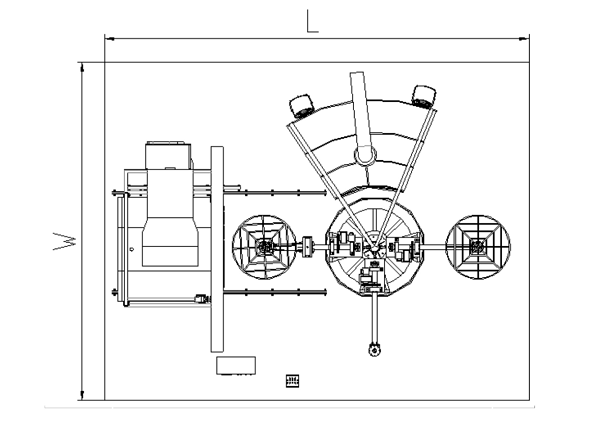

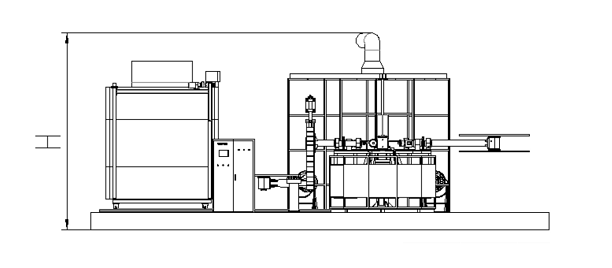

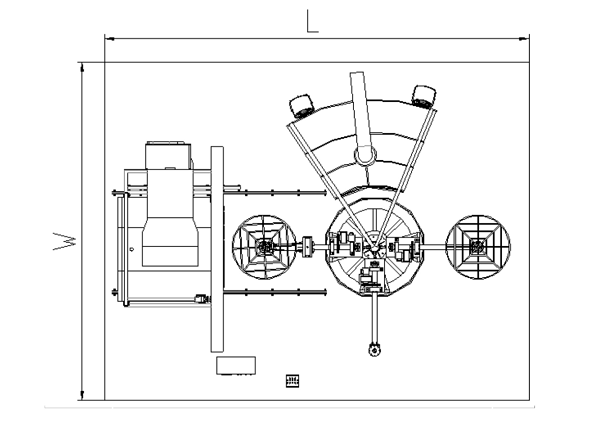

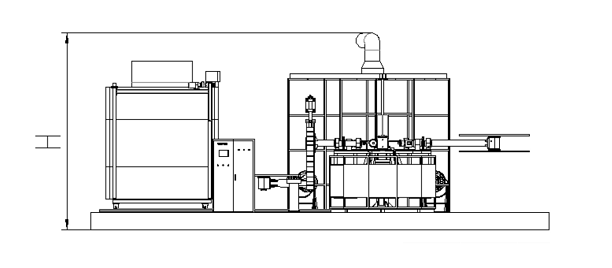

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS100 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Arm quantity: | 3 or 4 arms |

Carrousel rotational molding machine, its central tower bears the weight and the multi beams rotate synchronously. Its main characteristic is that it has relatively high reliability and practicability with simple and fast structure. It is good for producing relatively large products with different sizes but same of similar output frequency. It can bear three to four beams and three to four stations(heating, precooling, cooling and loading)

Characteristics of tower turning machine

Customers highly appreciate the tower type rotary molding machine for its exceptional stability and ability to produce continuously.

The three-arm turret type rotary molding machine boasts a central turret and three mobile cars, allowing for flexibility in choosing between four or five stations (heating, cooling, mold disassembly, preparation, and pre-cooling) based on the specific product requirements.

The four-arm turret rotary molding machine comes equipped with a central turret and four mobile cars, providing even more options for station selection. Depending on the product needs, users can choose from five or six stations (heating, cooling, mold disassembly, mold installation, preparation, and pre-cooling).

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS100 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Arm quantity: | 3 or 4 arms |