- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-3000TL

SNOWBALL

8477.4010.00

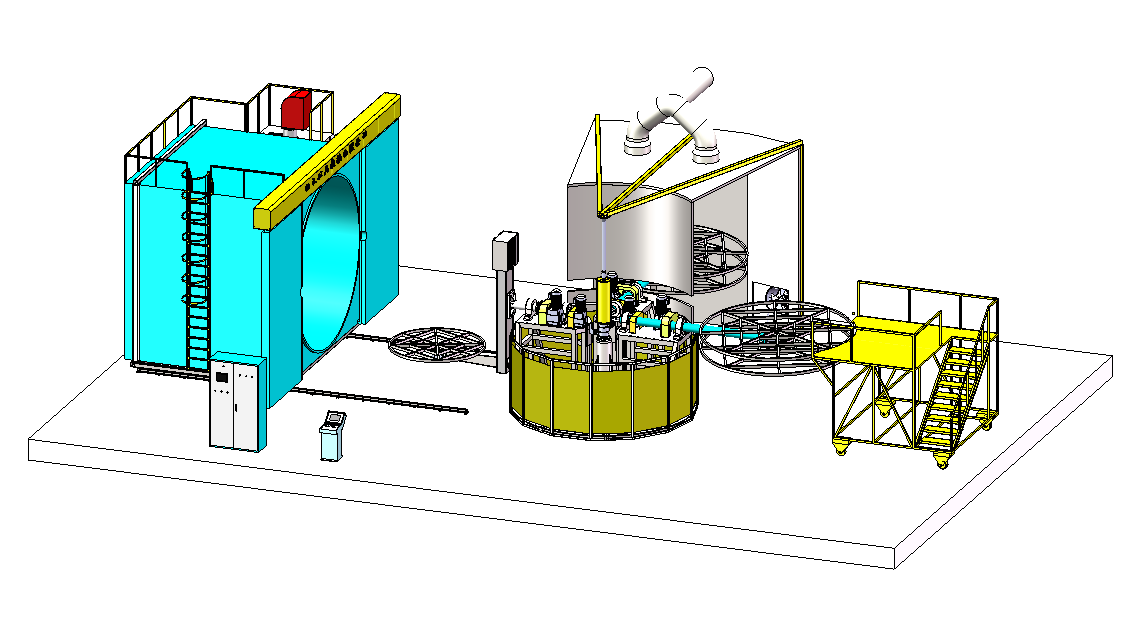

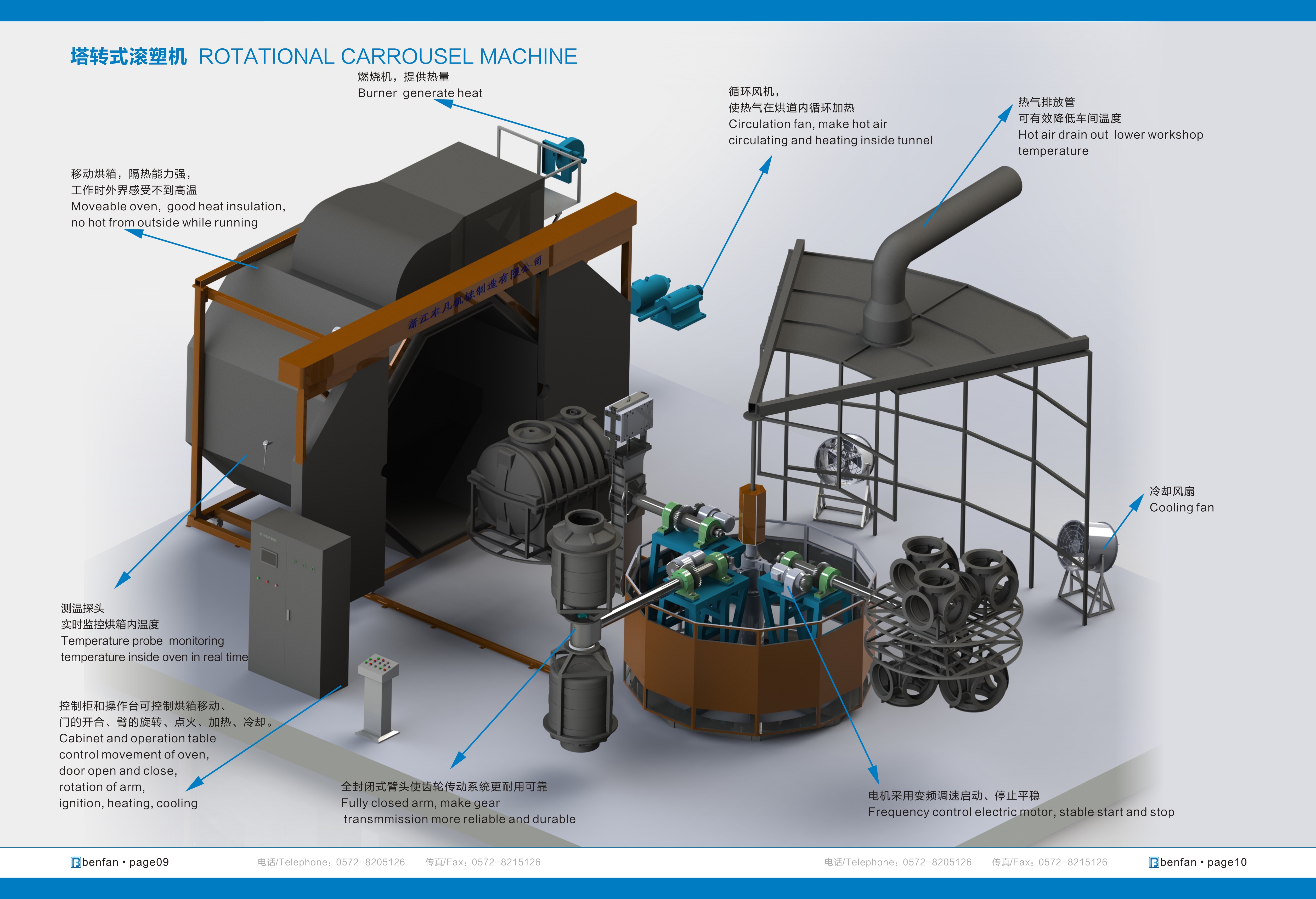

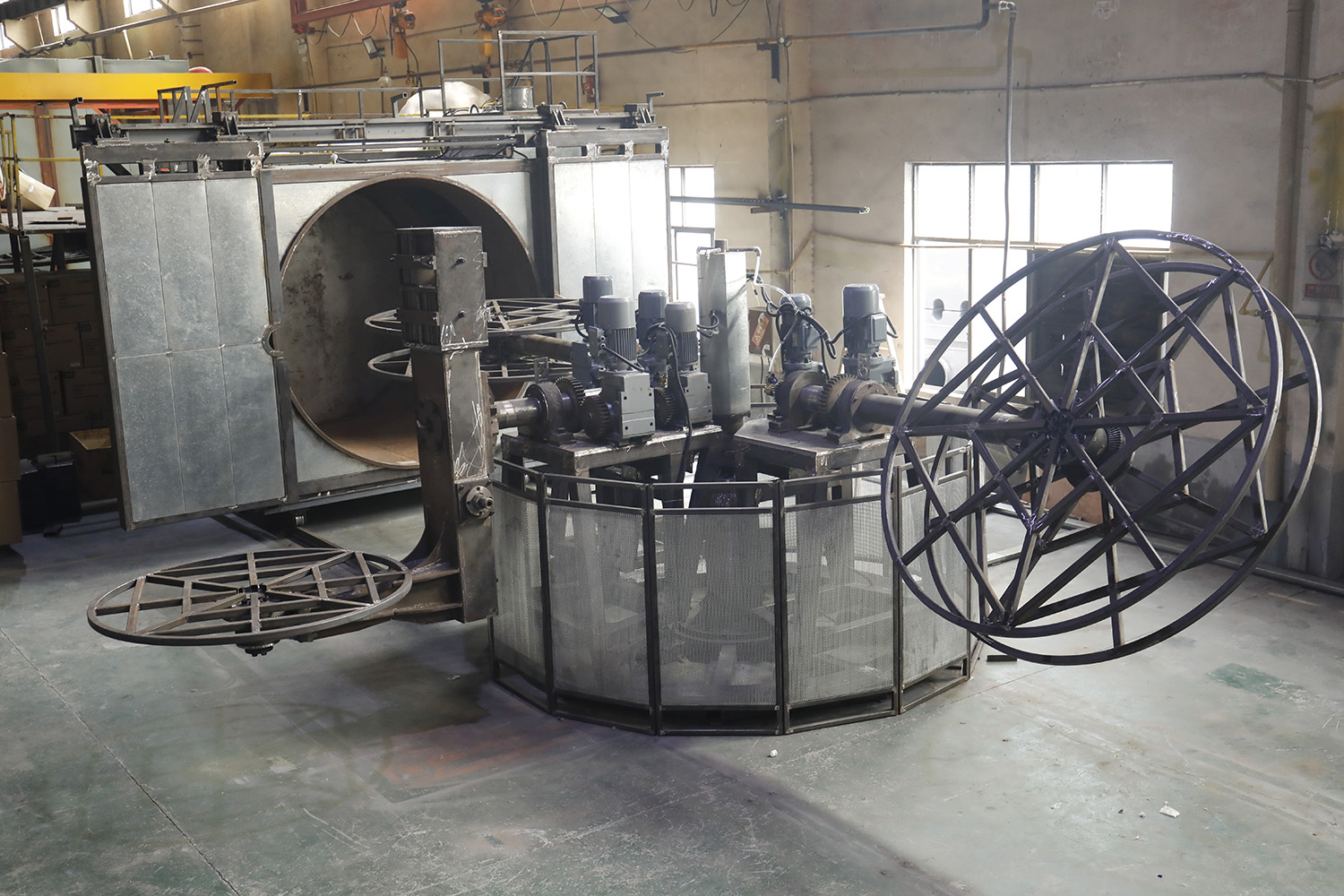

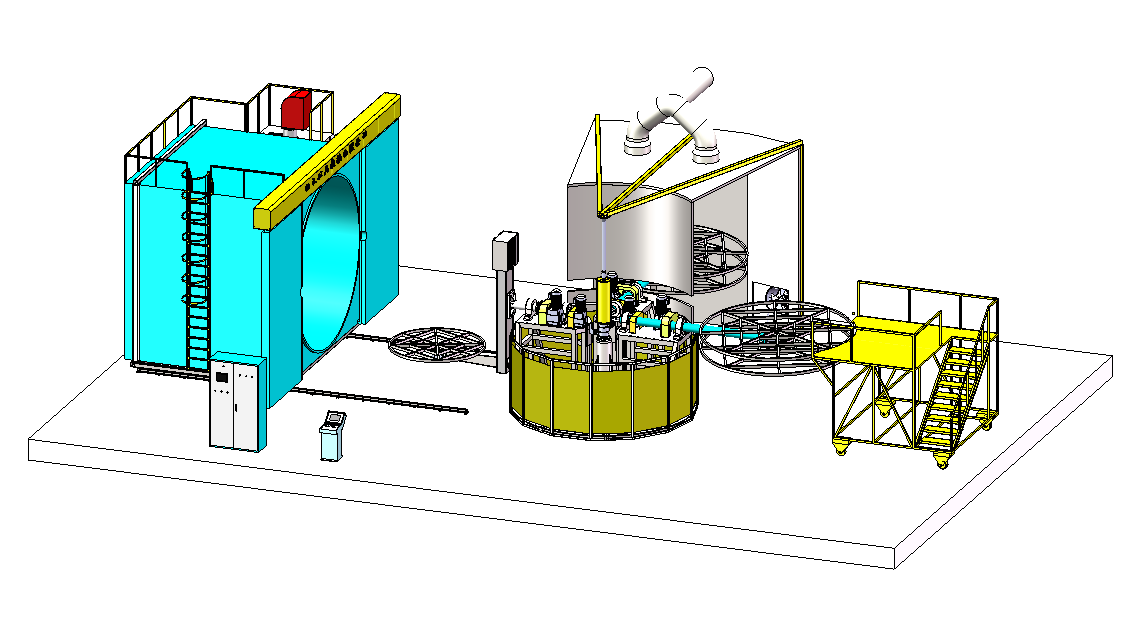

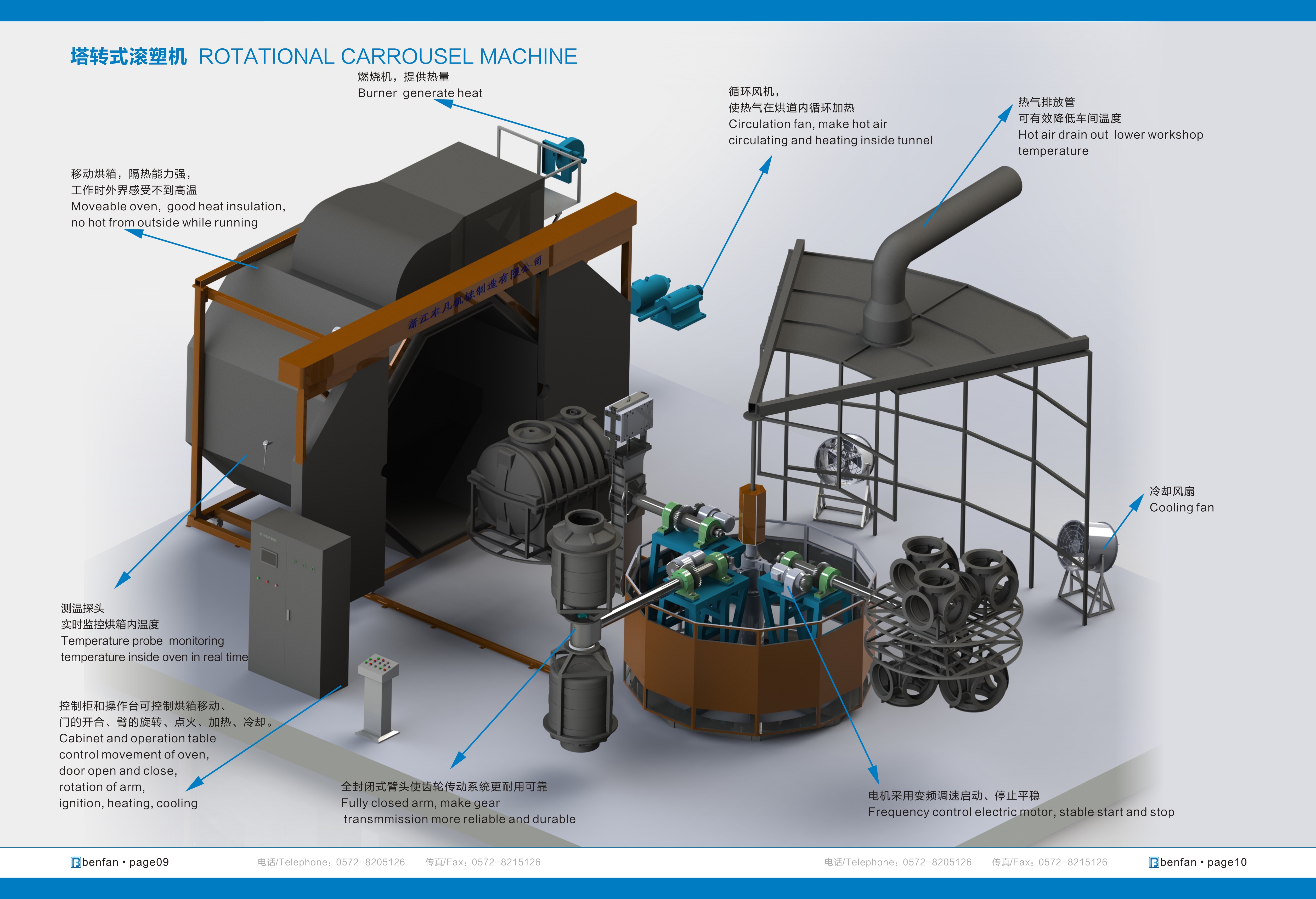

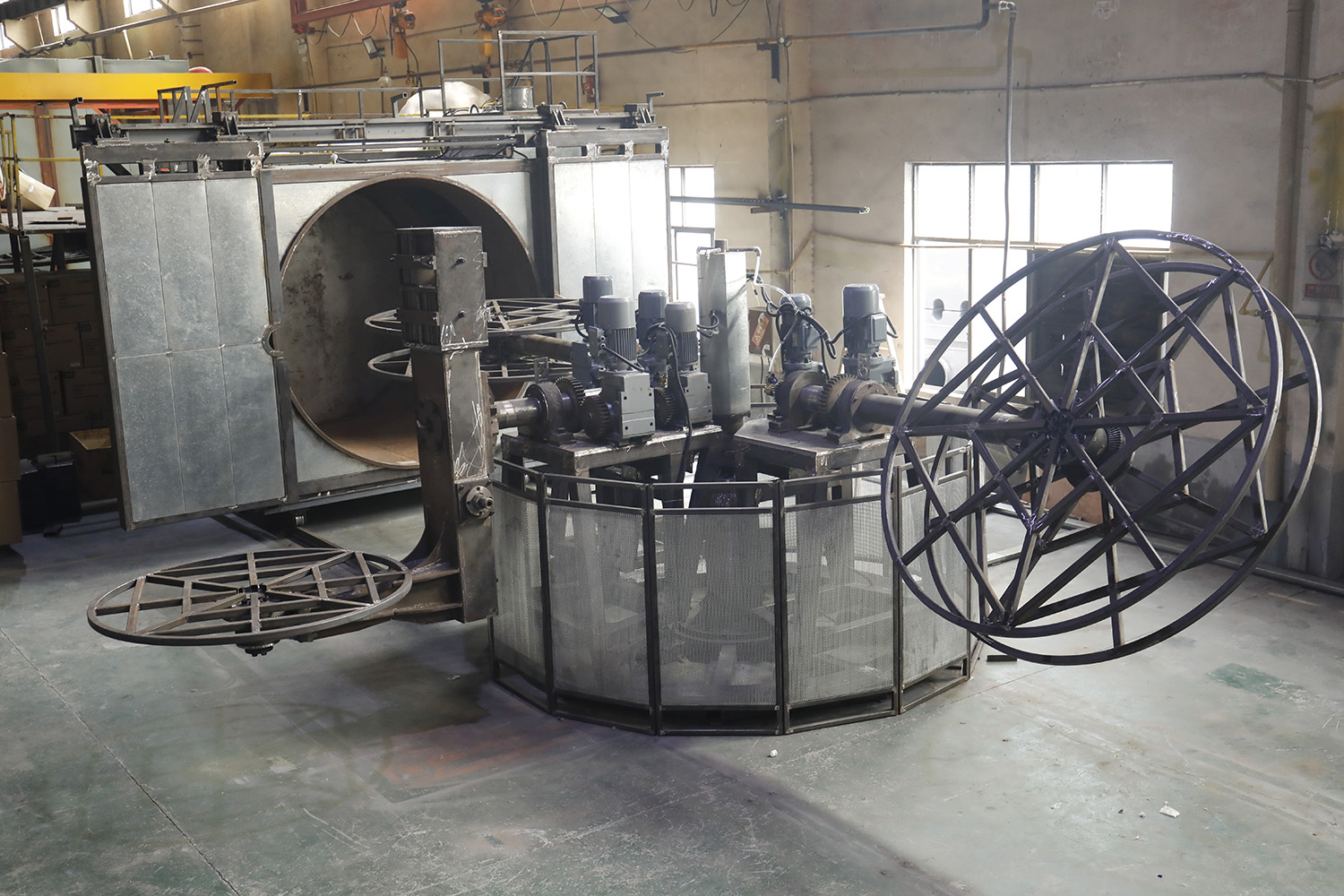

The carrousel rotomolding machine is a widely used equipment for molding. Each of its arms has an independent working and technological circle, including rotating speed, heating temperature, and cooling time. This makes it suitable for producing products with varying materials and thicknesses, making it flexible and highly efficient.

Additionally, this particular carrousel rotomolding machine is designed to be mobile and has a circular shape. It features only one door, which makes it energy-efficient and a popular choice. With the ability to have three or four hands, the output capacity of this machine can be increased by up to 30% compared to a shuttle rotomolding machine.

Technical data sheet:

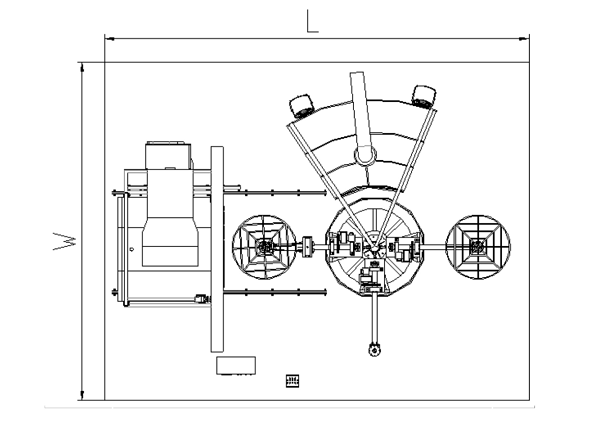

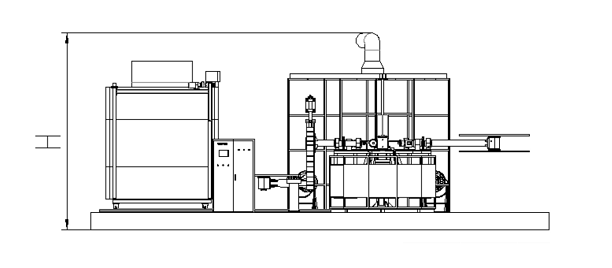

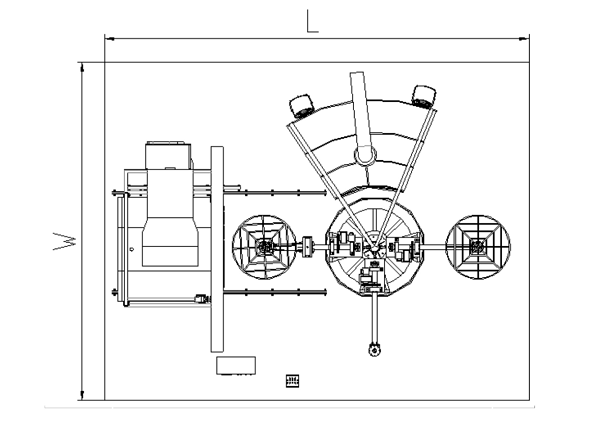

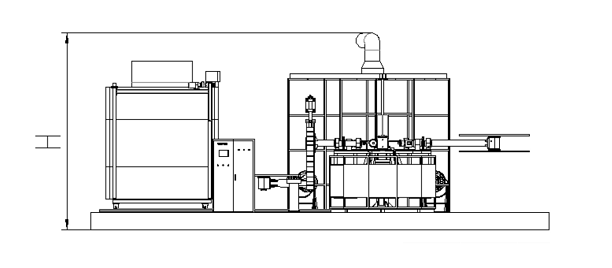

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS50 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Power: | 3 Phase, 380V,50HZ |

Machine Premium Features:

Space-saving: Our Carousel-type rolling plastic machine is designed to be very compact, and can be installed in any corner of your factory.

Energy-saving: Our machine adopts advanced energy-saving technology, reducing energy consumption to the lowest.

Safe and reliable: Our machine adopts multiple safety protection mechanisms to ensure the safety of operators.

Finally, we provide comprehensive after-sales services, including installation, debugging, maintenance, and training, ensuring your satisfaction and production efficiency.

Welcome to enquiry us! Rotate your business,Snowball your wealth!

The carrousel rotomolding machine is a widely used equipment for molding. Each of its arms has an independent working and technological circle, including rotating speed, heating temperature, and cooling time. This makes it suitable for producing products with varying materials and thicknesses, making it flexible and highly efficient.

Additionally, this particular carrousel rotomolding machine is designed to be mobile and has a circular shape. It features only one door, which makes it energy-efficient and a popular choice. With the ability to have three or four hands, the output capacity of this machine can be increased by up to 30% compared to a shuttle rotomolding machine.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS50 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Power: | 3 Phase, 380V,50HZ |

Machine Premium Features:

Space-saving: Our Carousel-type rolling plastic machine is designed to be very compact, and can be installed in any corner of your factory.

Energy-saving: Our machine adopts advanced energy-saving technology, reducing energy consumption to the lowest.

Safe and reliable: Our machine adopts multiple safety protection mechanisms to ensure the safety of operators.

Finally, we provide comprehensive after-sales services, including installation, debugging, maintenance, and training, ensuring your satisfaction and production efficiency.

Welcome to enquiry us! Rotate your business,Snowball your wealth!