- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-4000TL

SNOWBALL

8477.4010.00

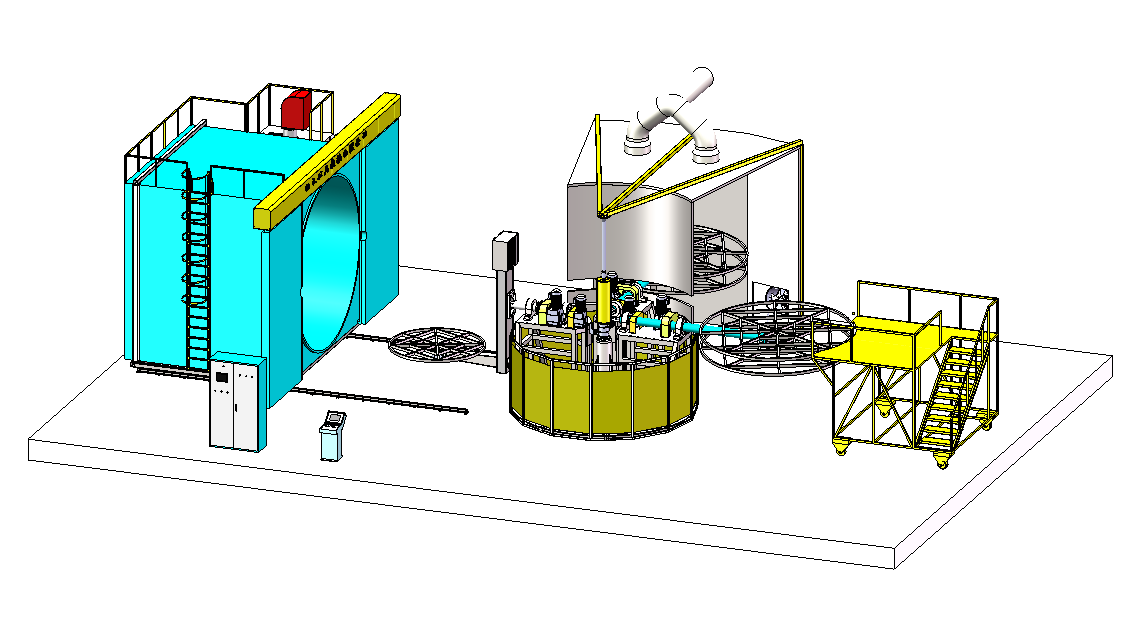

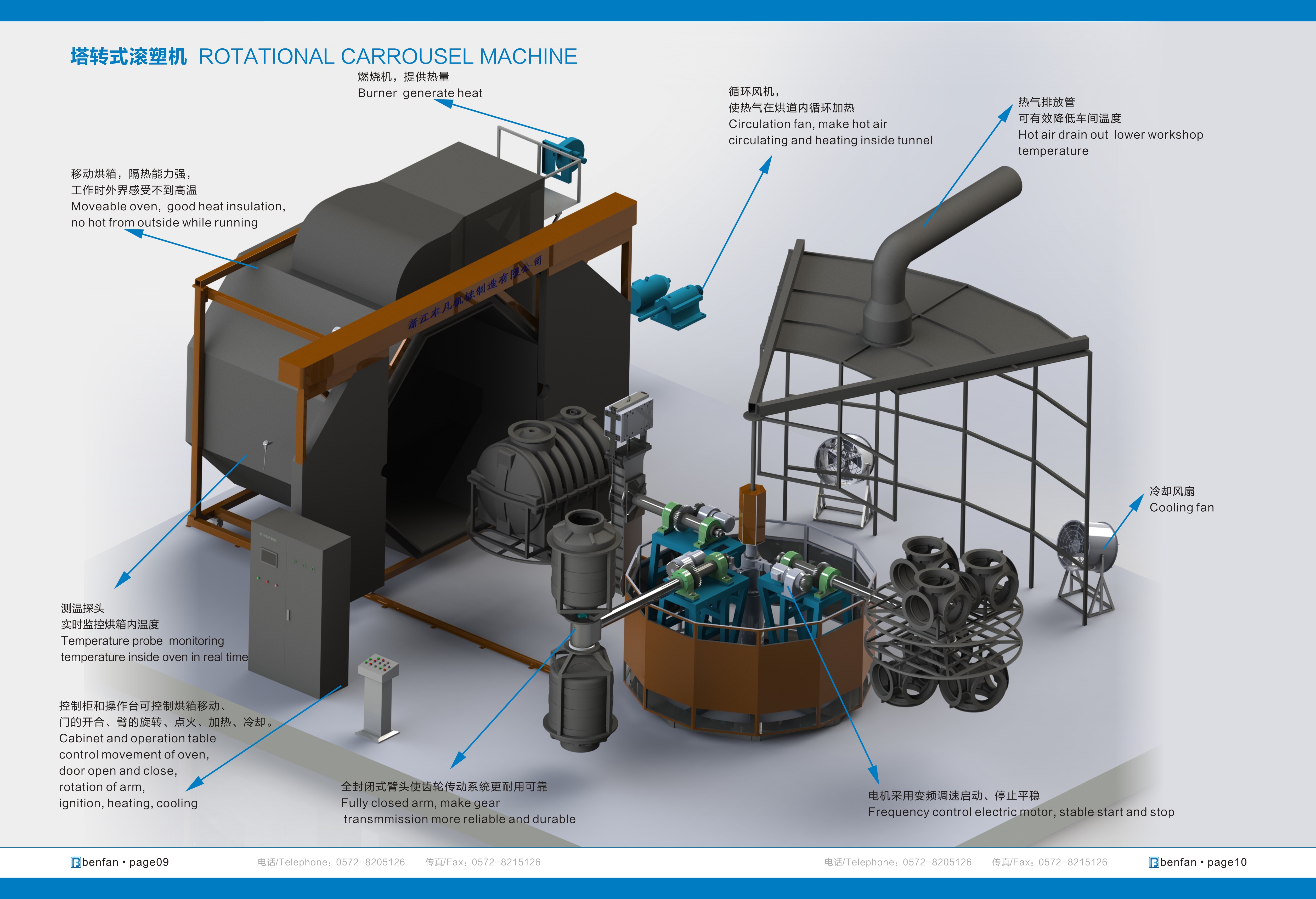

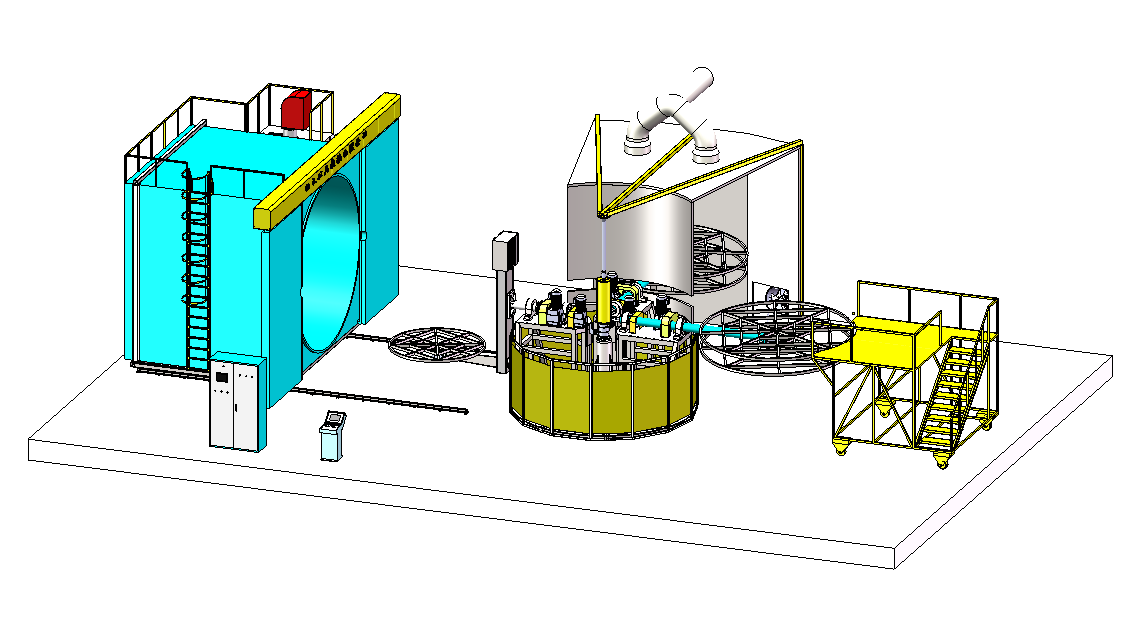

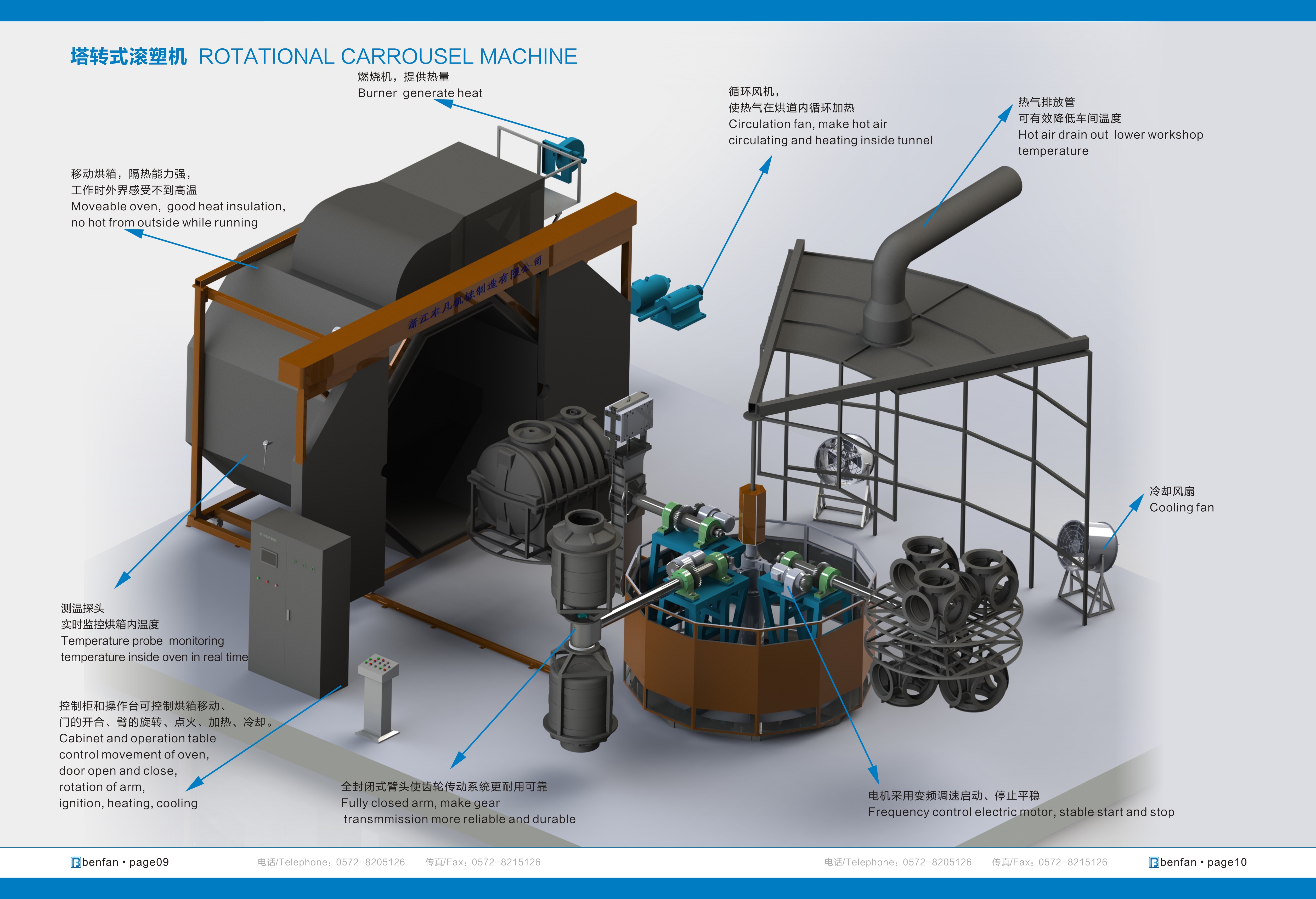

The carrousel rotomolding machine is a widely used molding equipment. Each arm operates independently with its own rotating speed, heating temperature, and cooling time, making it suitable for producing products with varying materials and thicknesses. This flexibility leads to high efficiency in production. Additionally, this machine is round in shape and can be moved easily. It has a single door, making it energy-efficient and a popular choice. If equipped with 3 or 4 arms, the output capacity can increase by up to 30% compared to a shuttle rotomolding machine.

Technical data sheet:

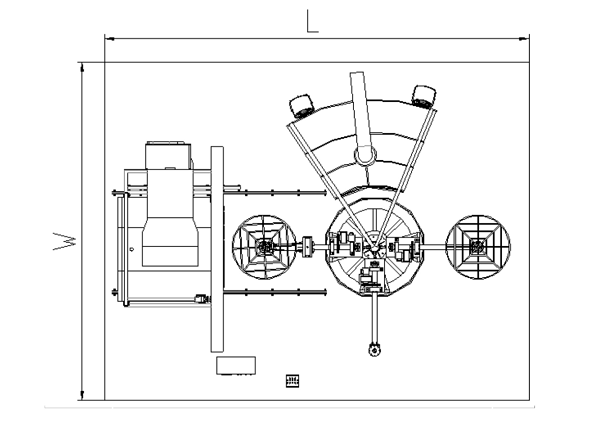

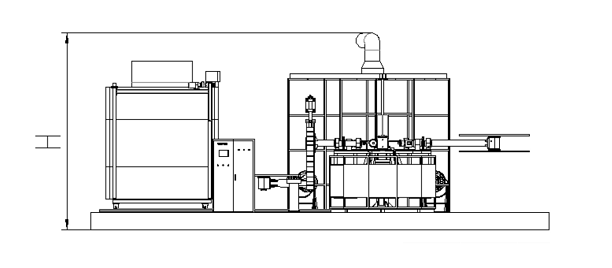

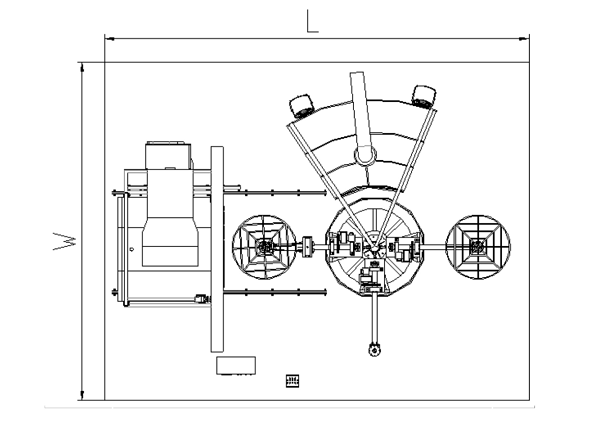

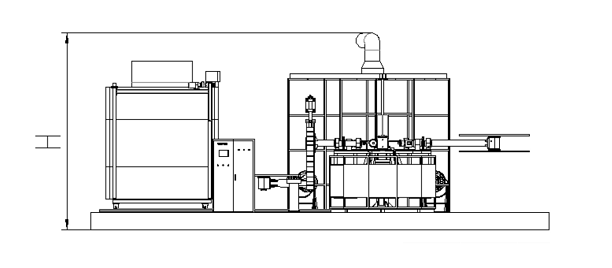

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Machine Premium Features:

Our cutting-edge technology is incorporated into our machine, catering to a wide range of requirements in the manufacturing of plastic products. Constructed with robust steel and top-notch electrical parts, our rolling plastic machine guarantees longevity and steadfastness.

What sets our machine apart is its ability to swiftly achieve automated production, resulting in significant savings in labor expenses and enhanced productivity. With user-friendly operation, our machine effortlessly carries out intricate plastic product manufacturing processes, ensuring uniformity and excellence in both large and small-scale production.

Welcome to enquiry us! Rotate your business,Snowball your wealth!

The carrousel rotomolding machine is a widely used molding equipment. Each arm operates independently with its own rotating speed, heating temperature, and cooling time, making it suitable for producing products with varying materials and thicknesses. This flexibility leads to high efficiency in production. Additionally, this machine is round in shape and can be moved easily. It has a single door, making it energy-efficient and a popular choice. If equipped with 3 or 4 arms, the output capacity can increase by up to 30% compared to a shuttle rotomolding machine.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Machine Premium Features:

Our cutting-edge technology is incorporated into our machine, catering to a wide range of requirements in the manufacturing of plastic products. Constructed with robust steel and top-notch electrical parts, our rolling plastic machine guarantees longevity and steadfastness.

What sets our machine apart is its ability to swiftly achieve automated production, resulting in significant savings in labor expenses and enhanced productivity. With user-friendly operation, our machine effortlessly carries out intricate plastic product manufacturing processes, ensuring uniformity and excellence in both large and small-scale production.

Welcome to enquiry us! Rotate your business,Snowball your wealth!