- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

2000-Rock and roll

SNOWBALL

8477.4010.00

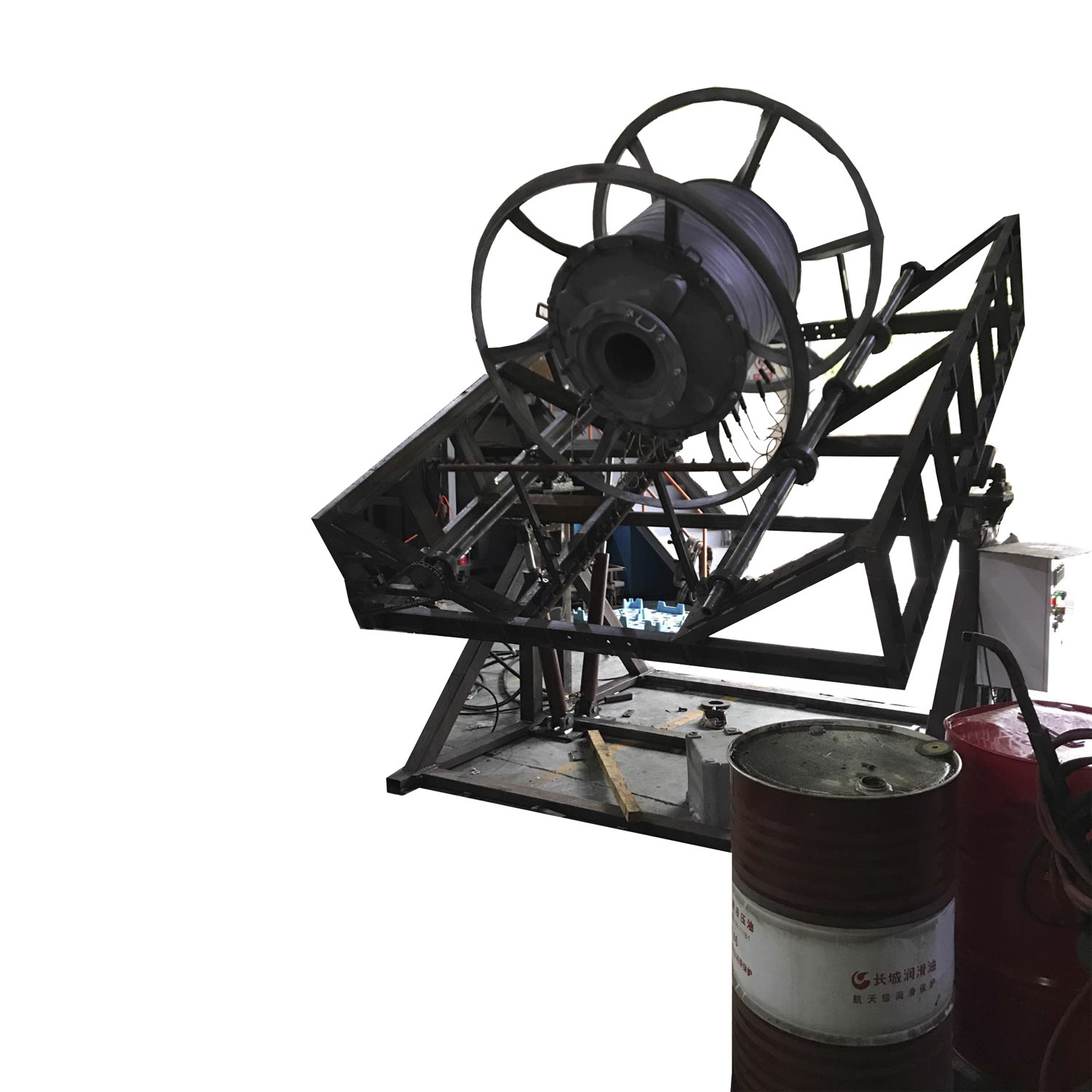

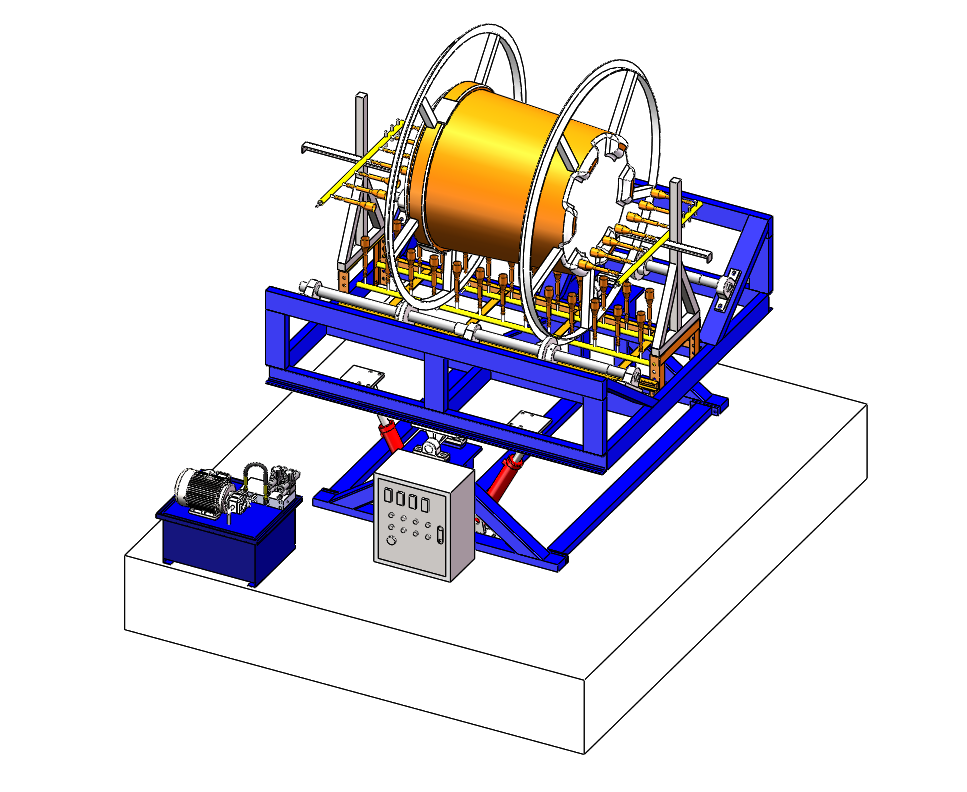

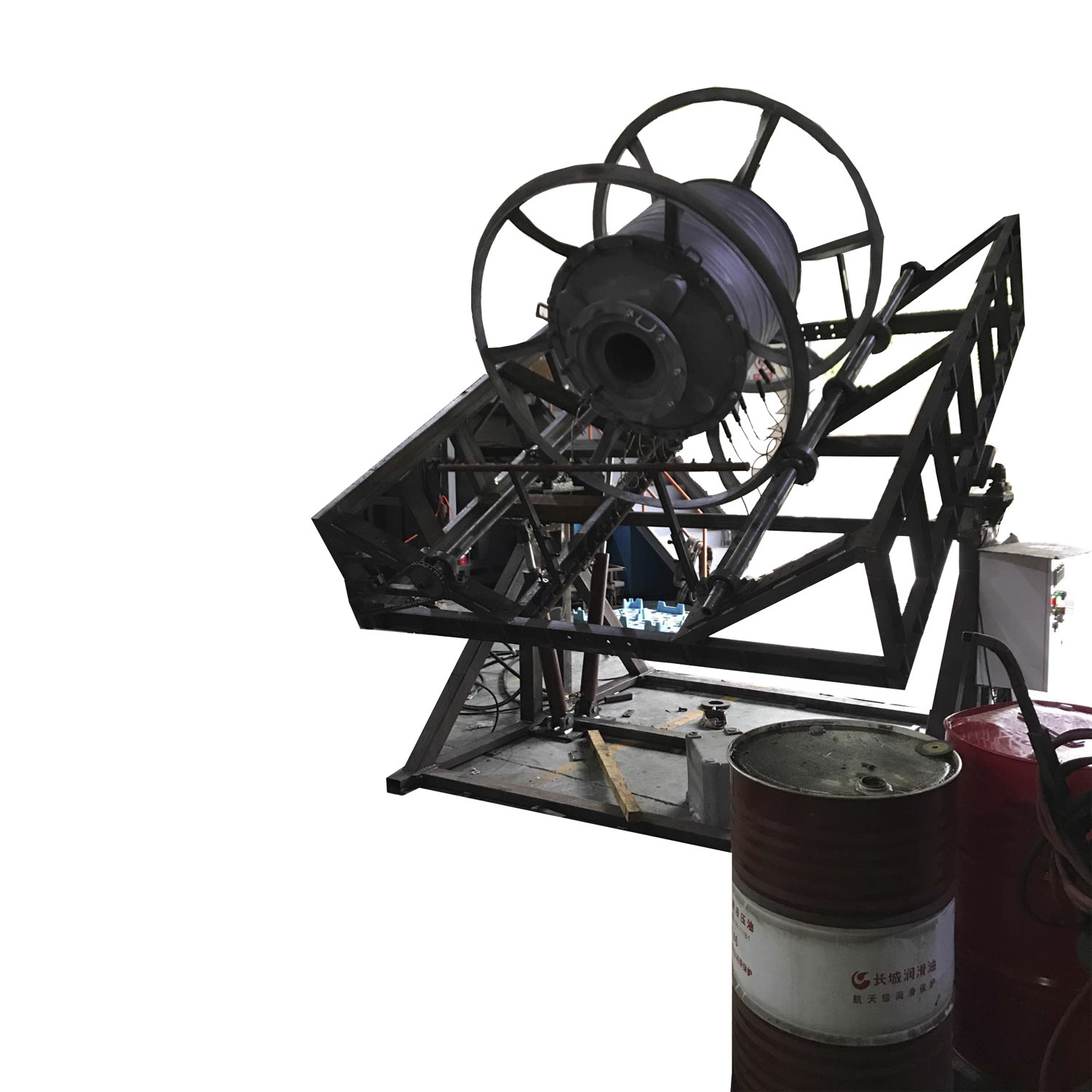

Introducing the rock and roll rotomolding machine with open flame, a top-of-the-line product designed for producing high-quality water tanks. This machine boasts advanced features that make it a must-have for any professional in the rotomolding industry.

With its state-of-the-art technology, this machine can produce water tanks that are durable, long-lasting, and resistant to wear and tear. The open flame feature ensures that the tanks are manufactured with precision and accuracy, ensuring that the final product is of the highest quality.

The rock and roll rotomolding machine is made using the latest materials and manufacturing techniques, ensuring that it is built to last. Its robust construction and sturdy design make it ideal for use in even the most demanding industrial environments.

This machine is easy to use, with user-friendly controls and an intuitive interface that makes it simple to operate. Its compact size and lightweight design make it easy to transport and store, making it the perfect choice for businesses of all sizes.

Overall, the rock and roll rotomolding machine with open flame is a top-quality product that is perfect for producing water tanks. Its advanced features, durable construction, and user-friendly design make it a must-have for anyone in the rotomolding industry. Order yours today and experience the difference for yourself!

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Machine Premium Features:

1. It only needs 3mins. from room temperature increase to 250 to 280 degree in oven

2. Arm made of special alloy material of good load

3. Full gear transmission, high efficiency

4. Full automatic operation with Siemens PLC.

5. Heavy duty oven and energy saving

6. Loading and unloading easy for mould

7. Special deep cavity heating technical, suitable for complicated product

8. Internet remote control (if the machine has problem in your factory, we can solve the problem through internet)

9. PLC and Motors are Siemens brand, Burner is RIELLO, Bearing is NSK from Japan, all electrical compenents are using Schneider brand.

10. Big computer screen, bob-weight system, special made motor, thermostability sealing arm head etc

11.Compare with European and US machine, our is lower price but reliable quality.

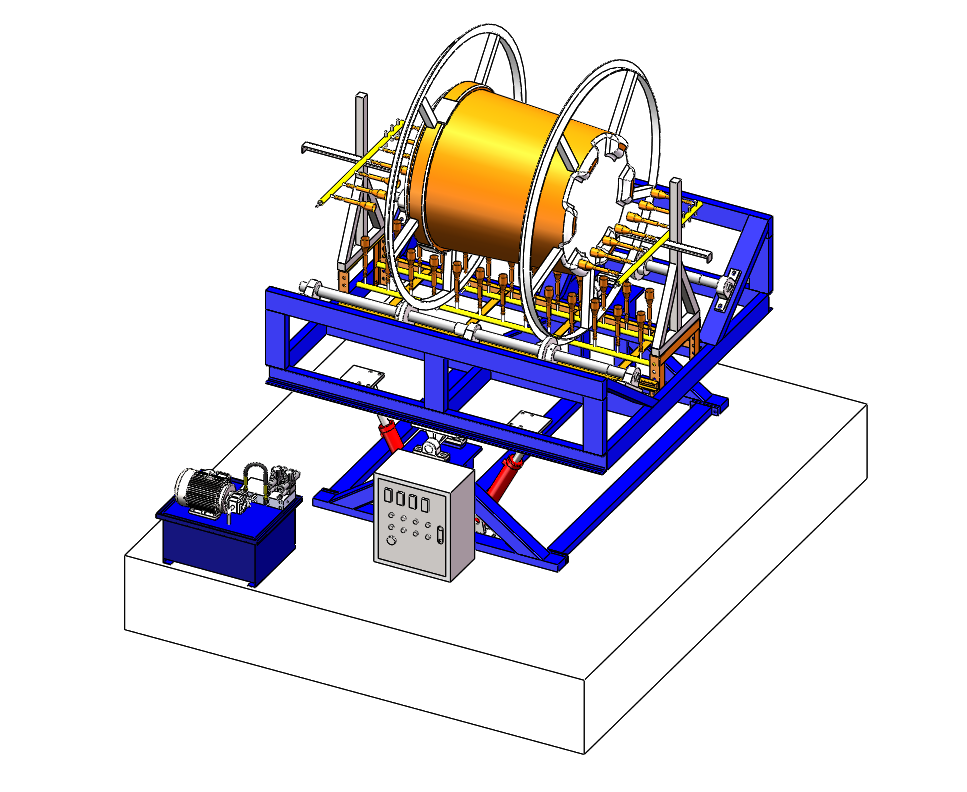

Introducing the rock and roll rotomolding machine with open flame, a top-of-the-line product designed for producing high-quality water tanks. This machine boasts advanced features that make it a must-have for any professional in the rotomolding industry.

With its state-of-the-art technology, this machine can produce water tanks that are durable, long-lasting, and resistant to wear and tear. The open flame feature ensures that the tanks are manufactured with precision and accuracy, ensuring that the final product is of the highest quality.

The rock and roll rotomolding machine is made using the latest materials and manufacturing techniques, ensuring that it is built to last. Its robust construction and sturdy design make it ideal for use in even the most demanding industrial environments.

This machine is easy to use, with user-friendly controls and an intuitive interface that makes it simple to operate. Its compact size and lightweight design make it easy to transport and store, making it the perfect choice for businesses of all sizes.

Overall, the rock and roll rotomolding machine with open flame is a top-quality product that is perfect for producing water tanks. Its advanced features, durable construction, and user-friendly design make it a must-have for anyone in the rotomolding industry. Order yours today and experience the difference for yourself!

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Machine Premium Features:

1. It only needs 3mins. from room temperature increase to 250 to 280 degree in oven

2. Arm made of special alloy material of good load

3. Full gear transmission, high efficiency

4. Full automatic operation with Siemens PLC.

5. Heavy duty oven and energy saving

6. Loading and unloading easy for mould

7. Special deep cavity heating technical, suitable for complicated product

8. Internet remote control (if the machine has problem in your factory, we can solve the problem through internet)

9. PLC and Motors are Siemens brand, Burner is RIELLO, Bearing is NSK from Japan, all electrical compenents are using Schneider brand.

10. Big computer screen, bob-weight system, special made motor, thermostability sealing arm head etc

11.Compare with European and US machine, our is lower price but reliable quality.