- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

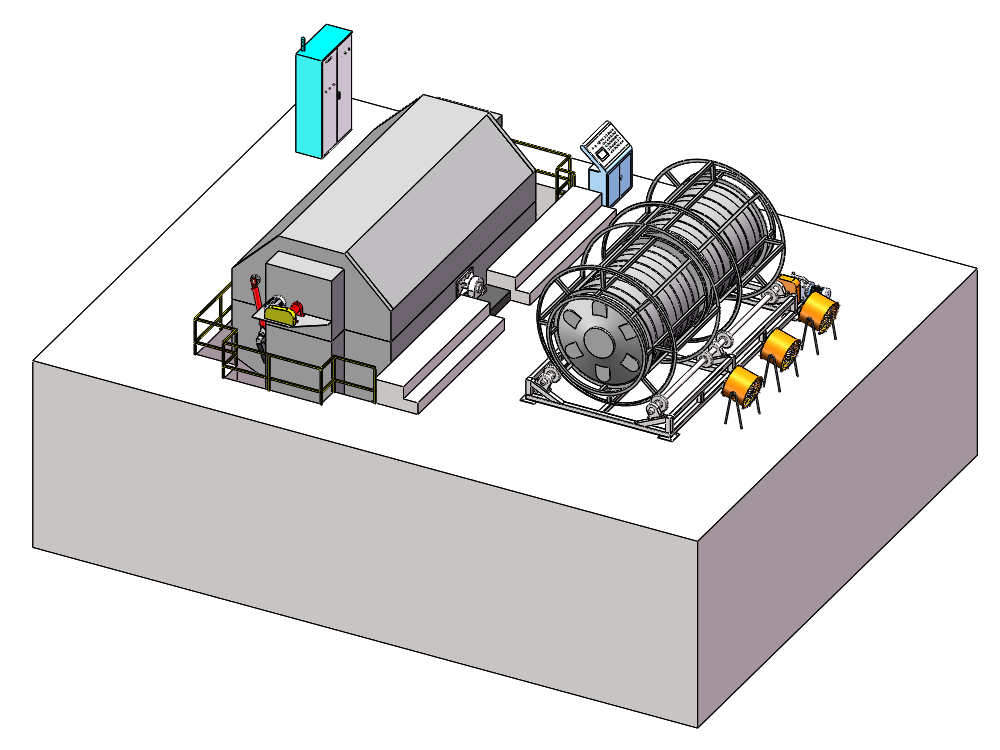

3500-Rock and roll

SNOWBALL

8477.4010.00

This kind of rock and roll machine is suitable to produce large long and thin mold, like kayak, boat etc.It is energy efficient,easy and the operation is simple by touching screen and full automatic control.

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Products that can be produced by rotational molding machine:

1. Water tanks: Rock and roll machines are commonly used for manufacturing water storage tanks of various sizes. The rotational movement of the machine helps ensure even distribution of the plastic material, resulting in a uniform wall thickness and structural integrity.

2. Septic tanks: Rock and roll rotomolding machines are ideal for producing septic tanks due to their ability to create large, seamless, and durable structures. The rotational motion allows for uniform thickness and strength throughout the tank, ensuring long-lasting performance.

3. Kayaks and canoes: The rock and roll process is well-suited for manufacturing kayaks and canoes. The machine's rotation enables the plastic material to evenly coat the mold, creating a strong and lightweight product with a smooth finish.

4. Playground equipment: Rock and roll rotomolding machines can produce various playground equipment, such as slides, climbers, and play structures. The process allows for the creation of intricate shapes and designs while maintaining durability and safety.

5. Large containers and bins: Rock and roll machines are commonly used for manufacturing large containers and bins used in industries such as agriculture, waste management, and industrial storage. The rotational movement ensures consistent wall thickness and strength throughout the product.

6. Automotive components: Some automotive components, such as fuel tanks, air ducts, and fenders, can be manufactured using rock and roll rotomolding machines. The process allows for the production of complex shapes and ensures high strength and durability.

7. Industrial tanks and containers: Rock and roll rotomolding machines are suitable for producing various industrial tanks and containers used for chemical storage, fuel storage, and material handling. The rotational motion ensures uniform thickness and structural integrity.

8. Outdoor furniture: Rock and roll machines can be used to manufacture outdoor furniture, including chairs, tables, and benches. The process allows for the creation of intricate designs and durable products that can withstand outdoor conditions.

These are just a few examples of the products that can be made using rock and roll rotomolding machines. The versatility of the process allows for the production of a wide range of large, hollow, and complex-shaped products.

Welcome to enquiry us! Rotate your business,Snowball your wealth!

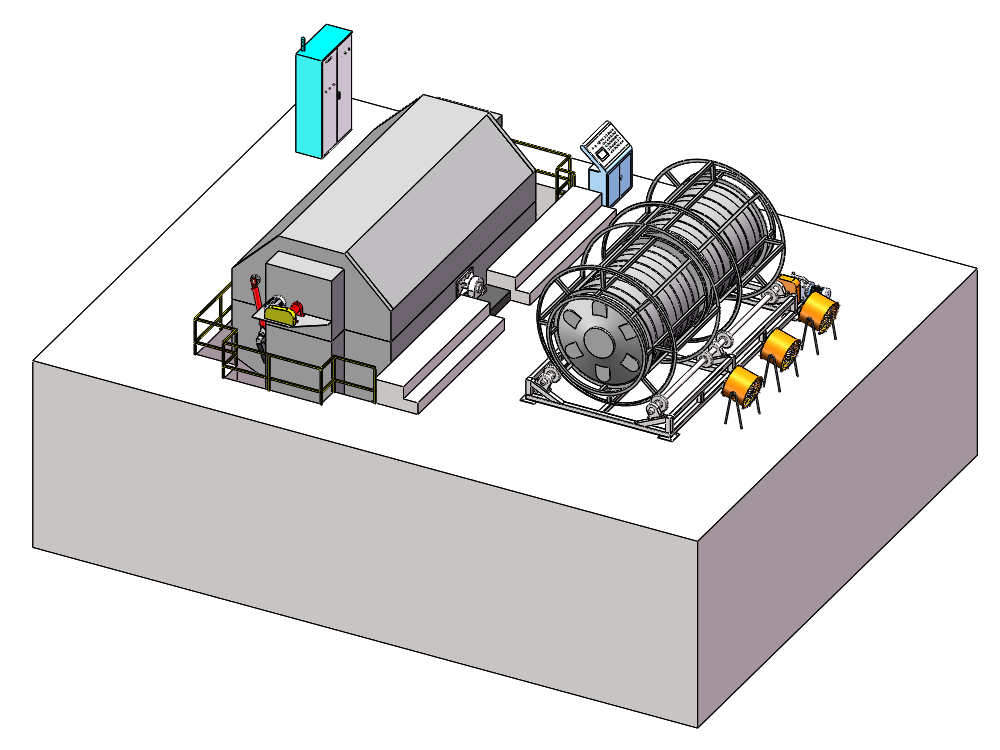

This kind of rock and roll machine is suitable to produce large long and thin mold, like kayak, boat etc.It is energy efficient,easy and the operation is simple by touching screen and full automatic control.

Machinery type: | Rock and Roll Oven rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Products that can be produced by rotational molding machine:

1. Water tanks: Rock and roll machines are commonly used for manufacturing water storage tanks of various sizes. The rotational movement of the machine helps ensure even distribution of the plastic material, resulting in a uniform wall thickness and structural integrity.

2. Septic tanks: Rock and roll rotomolding machines are ideal for producing septic tanks due to their ability to create large, seamless, and durable structures. The rotational motion allows for uniform thickness and strength throughout the tank, ensuring long-lasting performance.

3. Kayaks and canoes: The rock and roll process is well-suited for manufacturing kayaks and canoes. The machine's rotation enables the plastic material to evenly coat the mold, creating a strong and lightweight product with a smooth finish.

4. Playground equipment: Rock and roll rotomolding machines can produce various playground equipment, such as slides, climbers, and play structures. The process allows for the creation of intricate shapes and designs while maintaining durability and safety.

5. Large containers and bins: Rock and roll machines are commonly used for manufacturing large containers and bins used in industries such as agriculture, waste management, and industrial storage. The rotational movement ensures consistent wall thickness and strength throughout the product.

6. Automotive components: Some automotive components, such as fuel tanks, air ducts, and fenders, can be manufactured using rock and roll rotomolding machines. The process allows for the production of complex shapes and ensures high strength and durability.

7. Industrial tanks and containers: Rock and roll rotomolding machines are suitable for producing various industrial tanks and containers used for chemical storage, fuel storage, and material handling. The rotational motion ensures uniform thickness and structural integrity.

8. Outdoor furniture: Rock and roll machines can be used to manufacture outdoor furniture, including chairs, tables, and benches. The process allows for the creation of intricate designs and durable products that can withstand outdoor conditions.

These are just a few examples of the products that can be made using rock and roll rotomolding machines. The versatility of the process allows for the production of a wide range of large, hollow, and complex-shaped products.

Welcome to enquiry us! Rotate your business,Snowball your wealth!