- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-4000TL

SNOWBALL

8477.4010.00

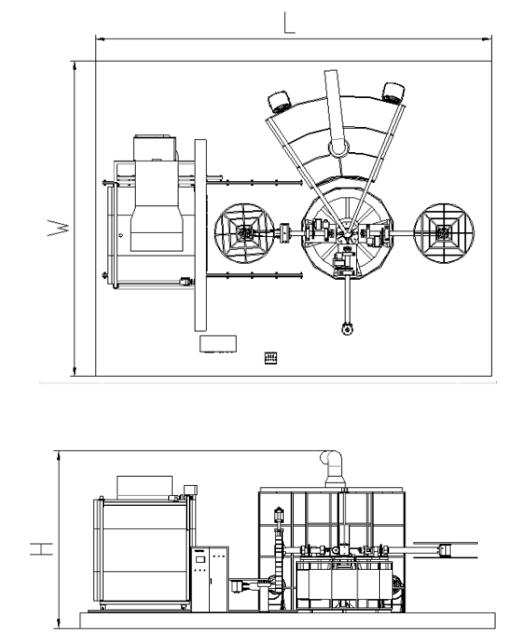

Carrousel Rotomoulding Machine Overview:

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular. With 3 or 4 hands, the output capacity can be higher 30% than shuttle rotomolding machine.

Product Parameters

| Category | Details |

|---|---|

| Product Name | Mobile Oven Carousel Rotomoulding Machine |

| Brand | SNOWBALL ROTO |

| Origin | China |

| Machine Type | Carrousel Rotomolding Machine |

| Heating Source | Natural gas, liquefied gas, diesel oil |

| Temperature Regulation | DTE Control with a 2°C tolerance |

| Burner System | Riello |

| Cooling System | Fan cooling |

| Control Method | Touch screen + PLC (Siemens brand) |

| Electrical Components | Schneider, Omron |

| Lead Time | Approximately 60 days after receipt of deposit |

| Installation Time (Overseas) | Varies based on machine size, typically takes 10-20 days |

| Heating Speed | Reaches 280°C from room temperature in 3 minutes |

Energy-efficient Heating Chamber: Designed for high efficiency and low energy consumption.

Automatic Combustion Control: Reduces fuel consumption and optimizes operation.

Gear-driven Transmission: Ensures stable and reliable machine performance.

Rapid and Uniform Cooling: The Mobile Oven Carousel Rotomoulding Machine ensures efficient cooling at the cooling station, minimizing deformation and improving product quality.

Self-diagnostic Alarm System: Increases productivity by identifying issues quickly.

Touch Screen Operation: Easy to learn and user-friendly interface.

Mobile Operation Platform: Flexible and convenient for various production setups.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 30 | 12 |

BF-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 16 |

BF-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 20 |

BF-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45 | 24 |

BF-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 45 | 26 |

BF-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 56 | 28 |

Higher Output: Carousel machines use multiple arms to rotate several molds at once, increasing production capacity compared to shuttle machines with only one mold carriage.

Faster Cycle Time: With simultaneous heating, cooling, and mold rotation, carousel machines achieve quicker cycle times and higher productivity.

Improved Efficiency: Continuous mold rotation minimizes idle time, maximizing machine utilization and production capacity.

Flexible Mold Sizes: Carousel machines can handle various mold sizes, offering greater flexibility in production, unlike shuttle machines which are more limited.

Lower Labor Needs: Carousel machines require less manual handling due to continuous mold rotation, reducing labor and improving operational efficiency.

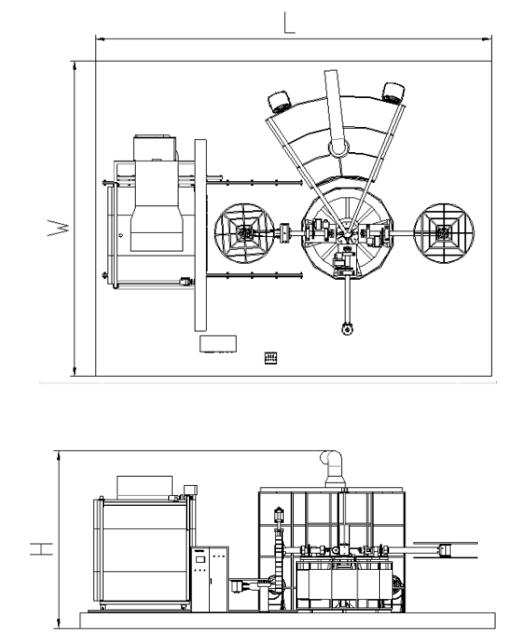

Carrousel Rotomoulding Machine Overview:

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular. With 3 or 4 hands, the output capacity can be higher 30% than shuttle rotomolding machine.

Product Parameters

| Category | Details |

|---|---|

| Product Name | Mobile Oven Carousel Rotomoulding Machine |

| Brand | SNOWBALL ROTO |

| Origin | China |

| Machine Type | Carrousel Rotomolding Machine |

| Heating Source | Natural gas, liquefied gas, diesel oil |

| Temperature Regulation | DTE Control with a 2°C tolerance |

| Burner System | Riello |

| Cooling System | Fan cooling |

| Control Method | Touch screen + PLC (Siemens brand) |

| Electrical Components | Schneider, Omron |

| Lead Time | Approximately 60 days after receipt of deposit |

| Installation Time (Overseas) | Varies based on machine size, typically takes 10-20 days |

| Heating Speed | Reaches 280°C from room temperature in 3 minutes |

Energy-efficient Heating Chamber: Designed for high efficiency and low energy consumption.

Automatic Combustion Control: Reduces fuel consumption and optimizes operation.

Gear-driven Transmission: Ensures stable and reliable machine performance.

Rapid and Uniform Cooling: The Mobile Oven Carousel Rotomoulding Machine ensures efficient cooling at the cooling station, minimizing deformation and improving product quality.

Self-diagnostic Alarm System: Increases productivity by identifying issues quickly.

Touch Screen Operation: Easy to learn and user-friendly interface.

Mobile Operation Platform: Flexible and convenient for various production setups.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 30 | 12 |

BF-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 16 |

BF-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 20 |

BF-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45 | 24 |

BF-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 45 | 26 |

BF-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 56 | 28 |

Higher Output: Carousel machines use multiple arms to rotate several molds at once, increasing production capacity compared to shuttle machines with only one mold carriage.

Faster Cycle Time: With simultaneous heating, cooling, and mold rotation, carousel machines achieve quicker cycle times and higher productivity.

Improved Efficiency: Continuous mold rotation minimizes idle time, maximizing machine utilization and production capacity.

Flexible Mold Sizes: Carousel machines can handle various mold sizes, offering greater flexibility in production, unlike shuttle machines which are more limited.

Lower Labor Needs: Carousel machines require less manual handling due to continuous mold rotation, reducing labor and improving operational efficiency.