- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-2500-Carousel-3A

SNOWBALL

8477.4010.00

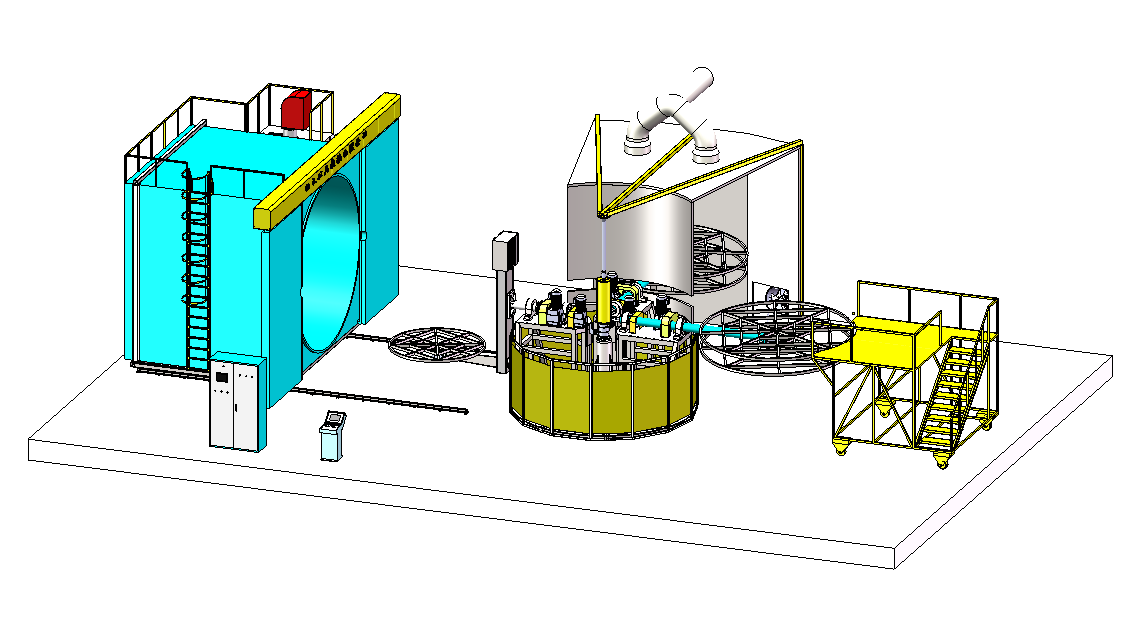

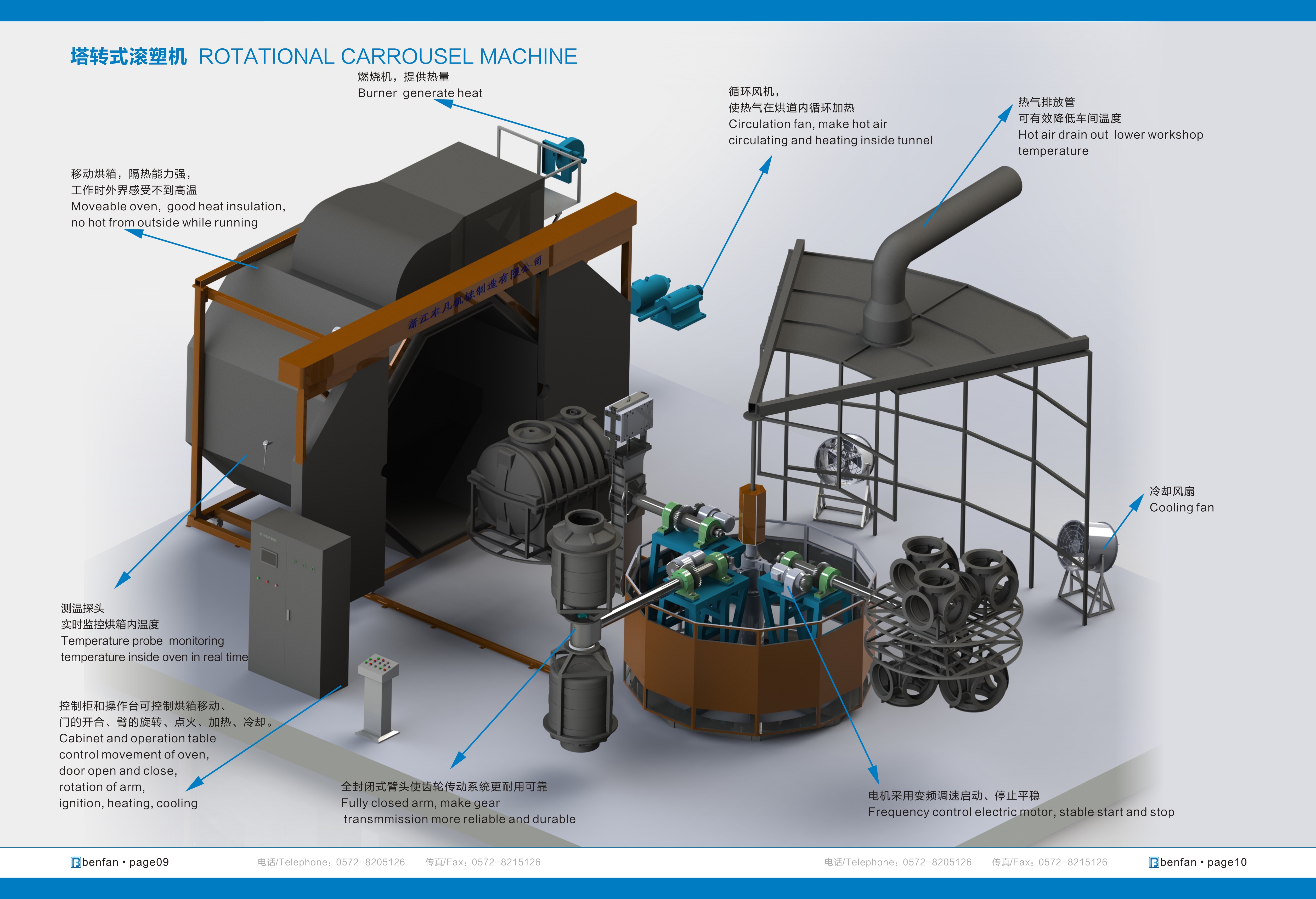

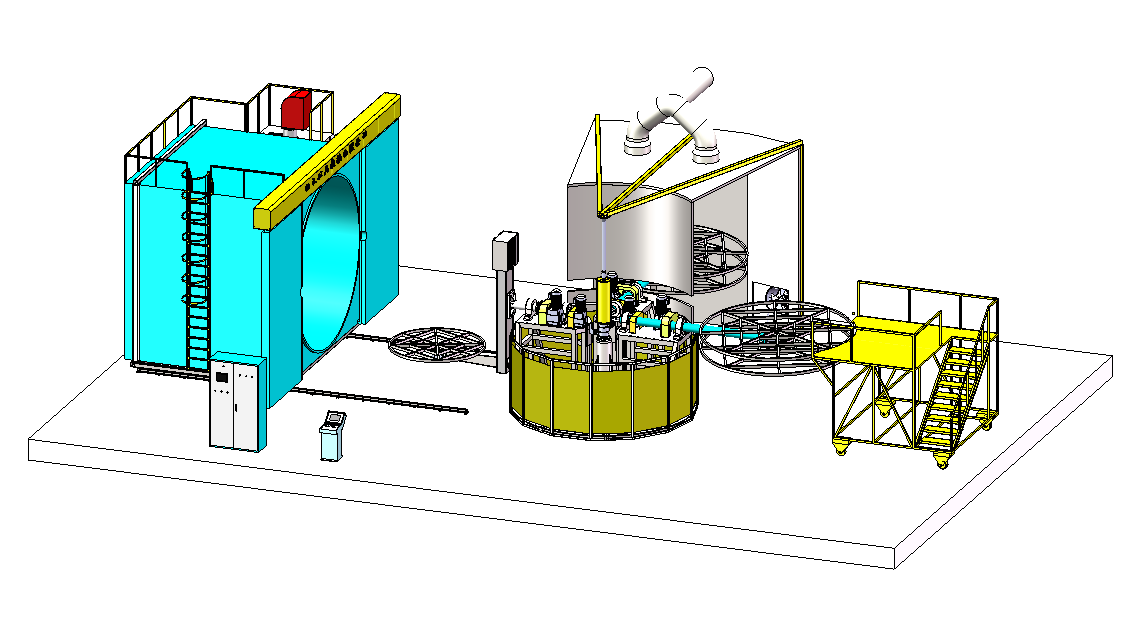

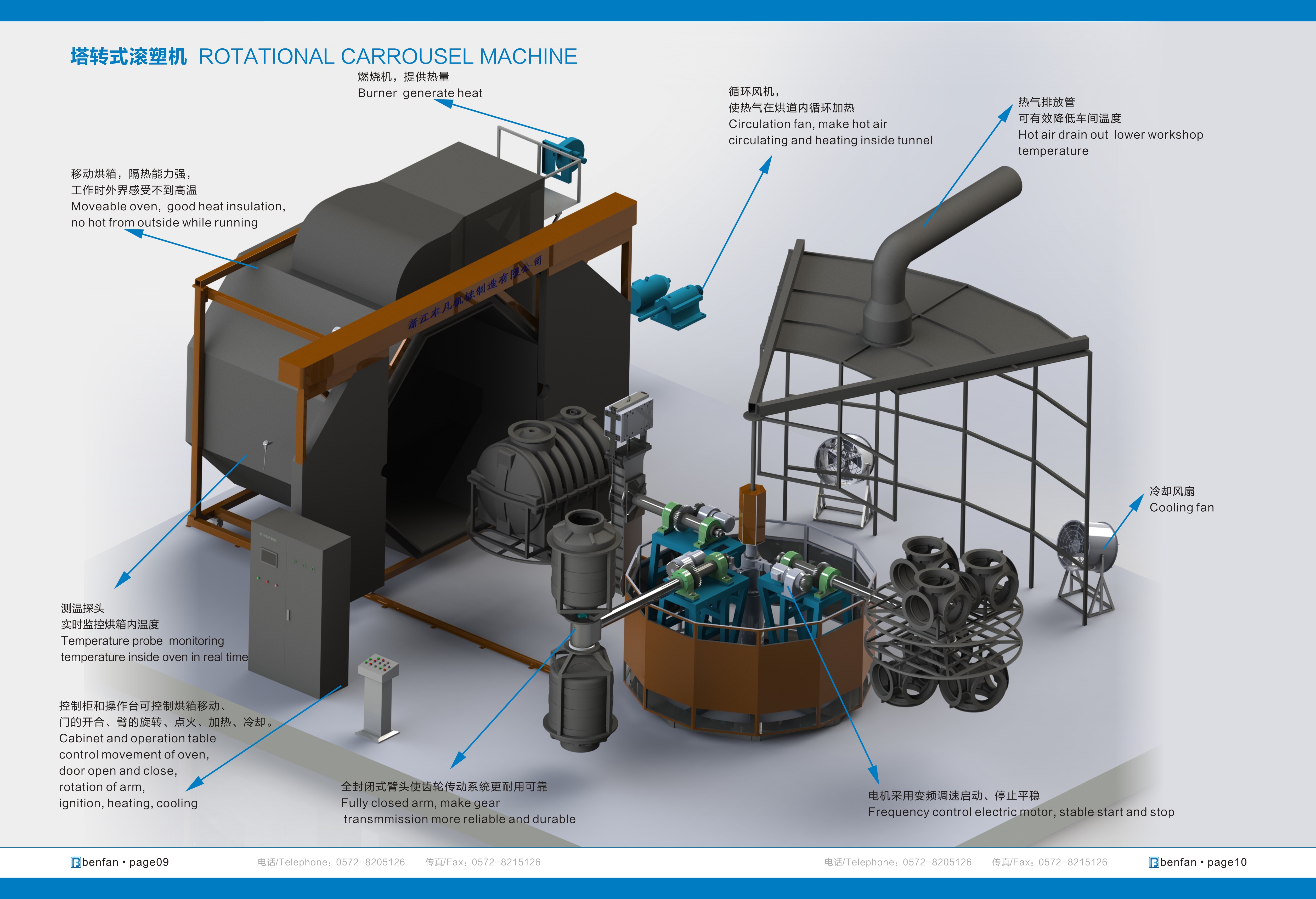

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular.

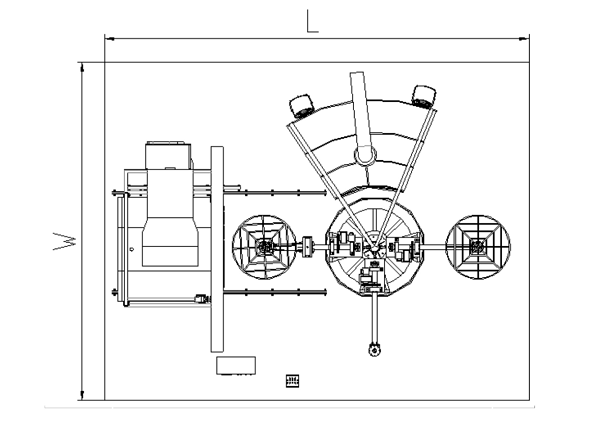

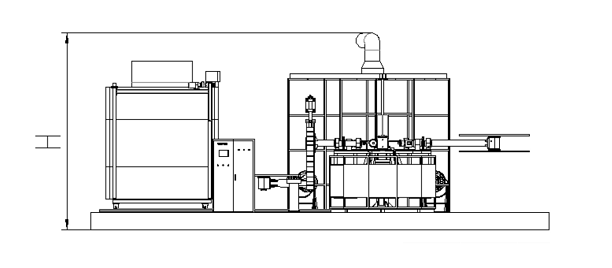

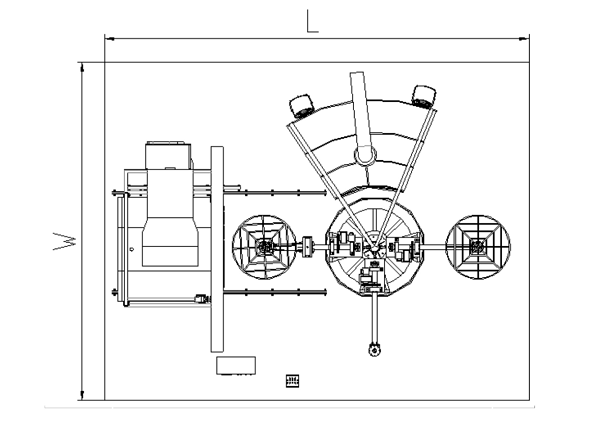

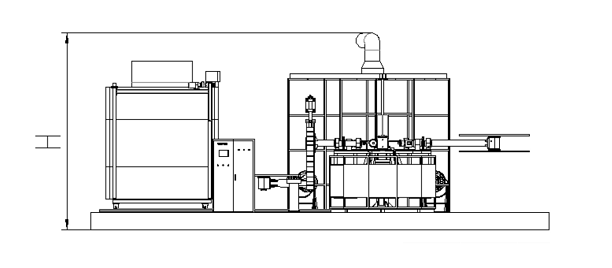

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Enhanced Efficiency: Maximize production output with our high-performance Carrousel rotomolding machine, enabling faster manufacturing of large, complex plastic products.

Energy Efficiency: Utilizing natural gas heating, our machine ensures efficient and cost-effective operation while maintaining consistent and uniform heating throughout the rotomolding process.

User-Friendly Operation: Easily set parameters, monitor processes, and make adjustments with our advanced PLC control system and user-friendly touchscreen interface, simplifying operation for operators.

Robust Construction: Built with heavy-duty steel, our Carrousel rotomolding machine guarantees durability, stability, and long-term reliability, minimizing maintenance requirements and maximizing uptime.

Safety Assurance: Designed with safety in mind, our machine complies with industry safety standards, providing a secure working environment for operators during the rotomolding process.

Technical Support and After-Sales Service: Benefit from our comprehensive technical support, including training, troubleshooting, and spare parts supply, ensuring smooth operation and minimizing downtime.

Customization Options: Tailor the machine to your specific needs with our range of customization options, such as additional heating zones or specialized molds, allowing you to create unique and customized plastic products.

Competitive Advantage: Our Carrousel rotomolding machine offers superior production efficiency, energy savings, and reliable performance, giving you a competitive edge in the market.

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

SN-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 2500L |

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

SN-3500ZC | Ø3500 | 17500 | 11500 | 5100 | 45.95 | 7000L |

SN-4000ZC | Ø4000 | 19500 | 13500 | 5600 | 56.60 | 10000L |

SN-4500ZC | Ø4500 | 21500 | 15500 | 6100 | 62.60 | 14000L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS20/RS34/RS50/RS70/RS100/RS130 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

Enhanced Efficiency: Maximize production output with our high-performance Carrousel rotomolding machine, enabling faster manufacturing of large, complex plastic products.

Energy Efficiency: Utilizing natural gas heating, our machine ensures efficient and cost-effective operation while maintaining consistent and uniform heating throughout the rotomolding process.

User-Friendly Operation: Easily set parameters, monitor processes, and make adjustments with our advanced PLC control system and user-friendly touchscreen interface, simplifying operation for operators.

Robust Construction: Built with heavy-duty steel, our Carrousel rotomolding machine guarantees durability, stability, and long-term reliability, minimizing maintenance requirements and maximizing uptime.

Safety Assurance: Designed with safety in mind, our machine complies with industry safety standards, providing a secure working environment for operators during the rotomolding process.

Technical Support and After-Sales Service: Benefit from our comprehensive technical support, including training, troubleshooting, and spare parts supply, ensuring smooth operation and minimizing downtime.

Customization Options: Tailor the machine to your specific needs with our range of customization options, such as additional heating zones or specialized molds, allowing you to create unique and customized plastic products.

Competitive Advantage: Our Carrousel rotomolding machine offers superior production efficiency, energy savings, and reliable performance, giving you a competitive edge in the market.