- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-3000TL

SNOWBALL

8477.4010.00

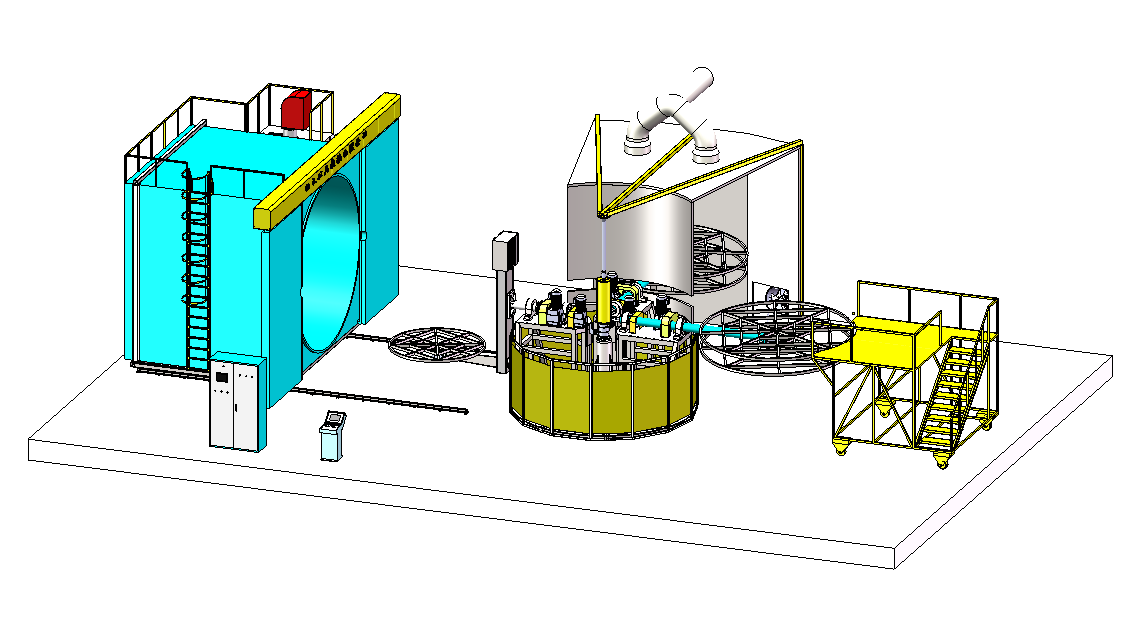

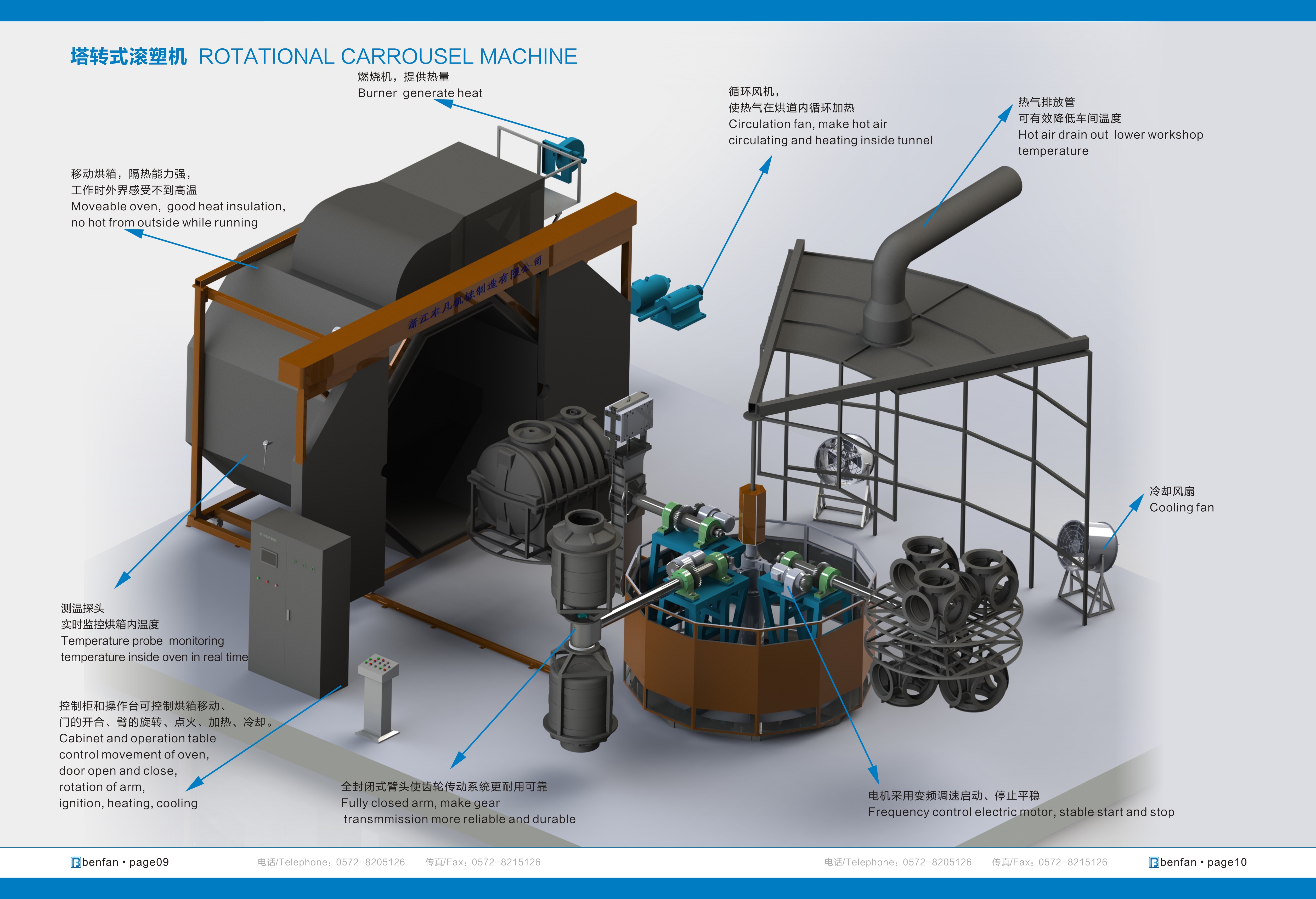

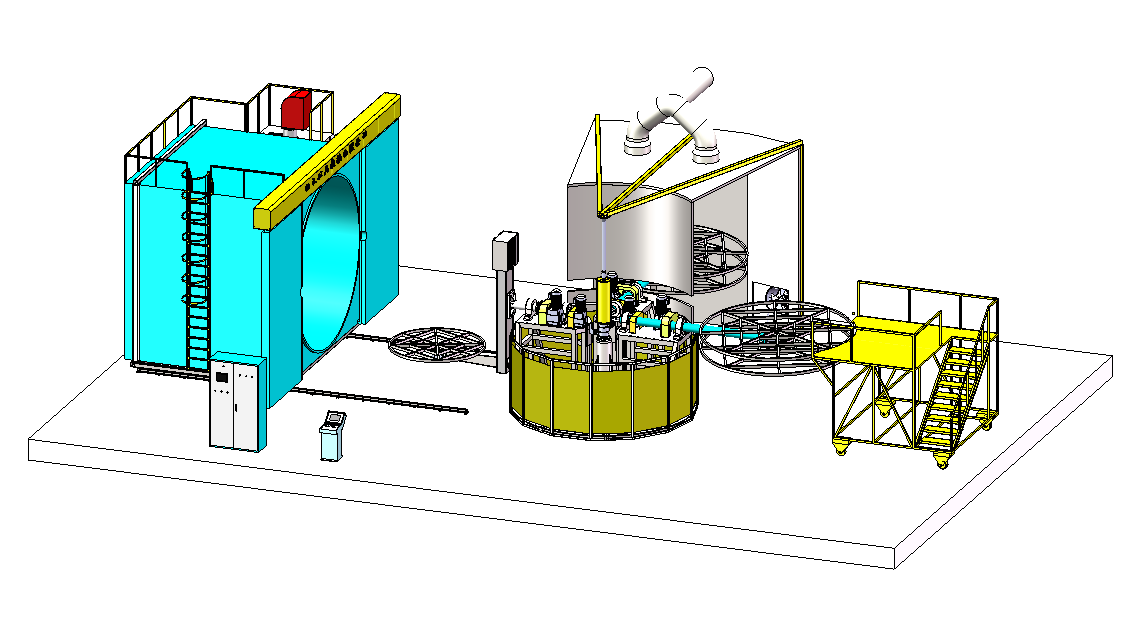

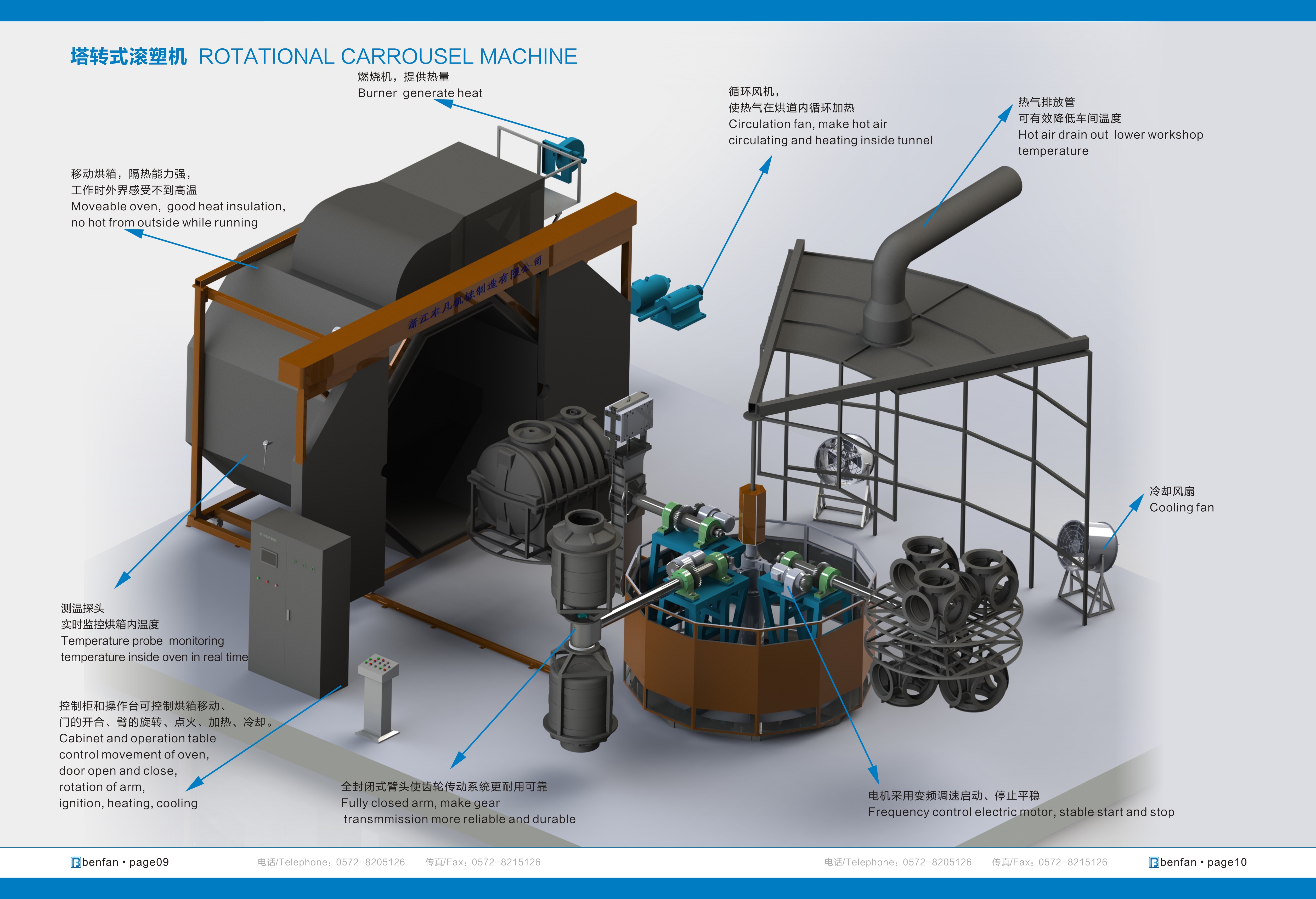

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular.

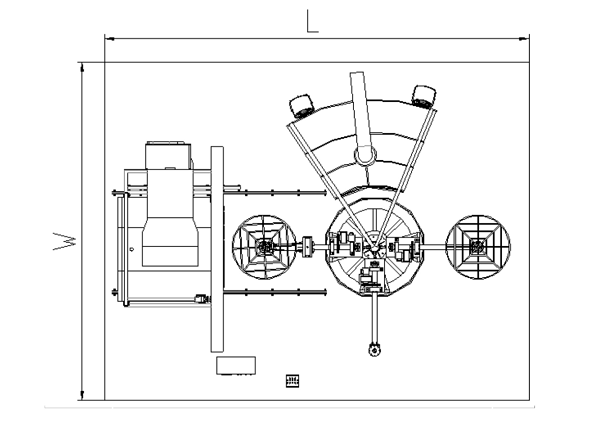

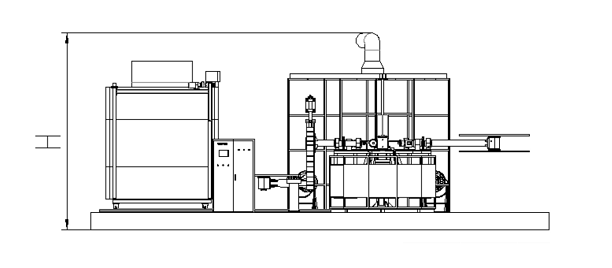

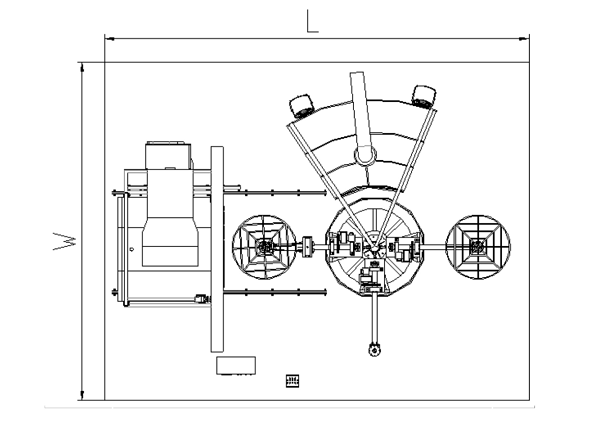

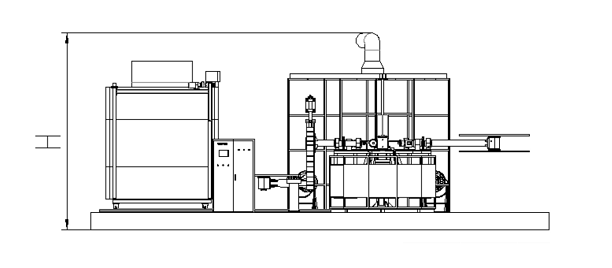

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS50 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Arm shape: | Striaght arm/L arm/C arm/U arm |

1, PLC--- Siemens S7-200

2, Touch screen(Siemens, 10.4”)

3, Frequency Changer (Invertor) ---- Siemens

4, Electric Unit --- Schneider

5, Burner --- Riello (RS50)

6, Limit switch--- OMRON,

7, The emergency switch use Schneider brand

8, The motors are used with Siemens brand, gear box : Redsun (Chinese first class brand)

9, Diameter of the Shaft is 232mm, thickness of the wall 55mm

10, Thickness of oven wall120mm

11, Air piping inside the arm for air blow device

12, Rotation plate is included.

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular.

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-3000ZC | Ø3000 | 15500 | 10500 | 4500 | 35 | 4500L |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS50 |

Cooling mode: | Fan cooling or water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 60 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Arm shape: | Striaght arm/L arm/C arm/U arm |

1, PLC--- Siemens S7-200

2, Touch screen(Siemens, 10.4”)

3, Frequency Changer (Invertor) ---- Siemens

4, Electric Unit --- Schneider

5, Burner --- Riello (RS50)

6, Limit switch--- OMRON,

7, The emergency switch use Schneider brand

8, The motors are used with Siemens brand, gear box : Redsun (Chinese first class brand)

9, Diameter of the Shaft is 232mm, thickness of the wall 55mm

10, Thickness of oven wall120mm

11, Air piping inside the arm for air blow device

12, Rotation plate is included.