- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

3000-OMS-3A

SNOWBALL

8477.4010.00

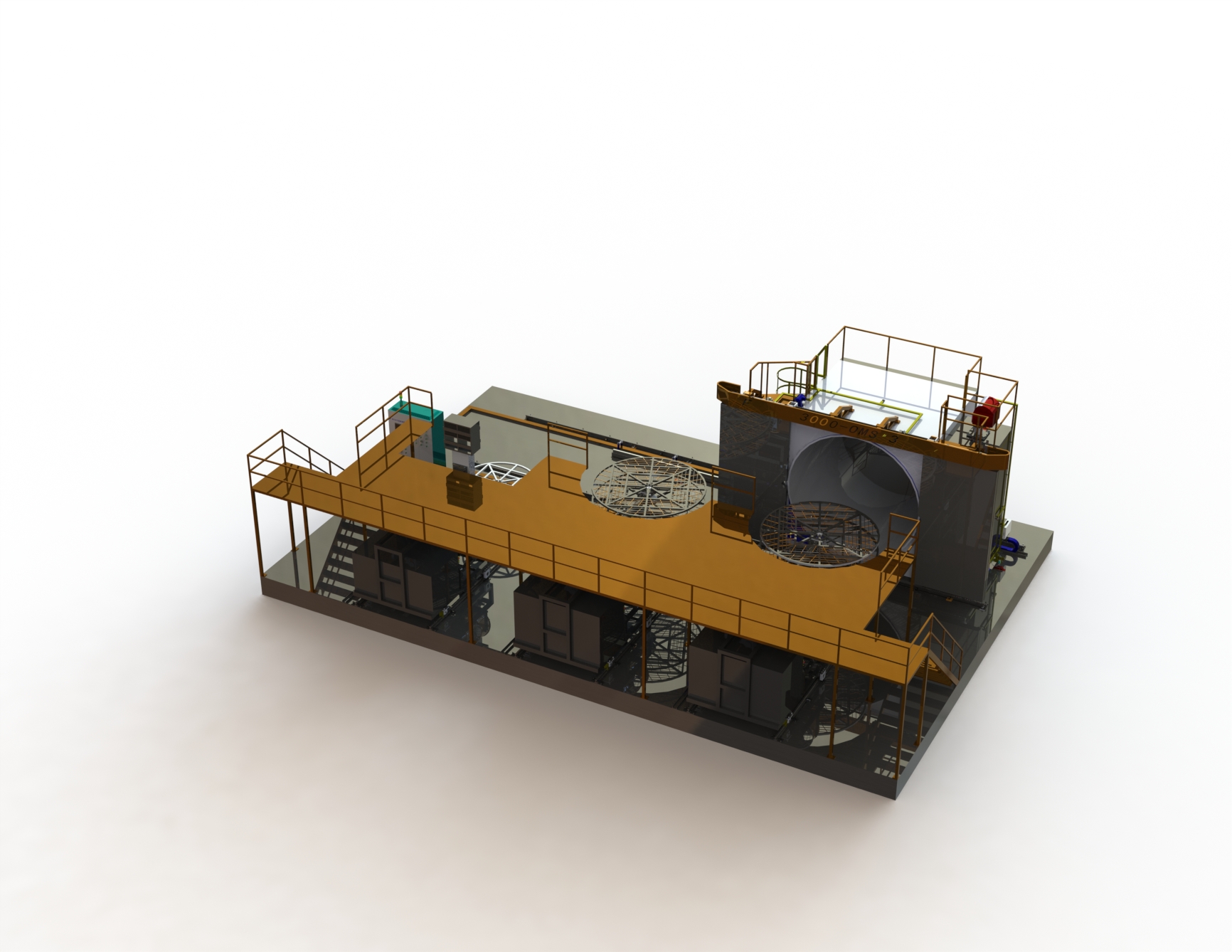

An oven moveable shuttle machine, also known as a shuttle oven rotational molding machine, is a type of rotomolding machine that utilizes a shuttle system to transfer molds in and out of the oven during the rotational molding process.

In a shuttle oven machine, the oven chamber is moveable, while the molds are moved in and out of the oven for heating, cooling, and demolding. The shuttle system typically consists of a mechanical or hydraulic mechanism that transports the molds between the oven and the loading/unloading stations.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-1000OM | Ø1000 | 6500 | 4500 | 1900 | 20.8 | 8 |

BF-1600OM | Ø1600 | 9000 | 6000 | 2900 | 29.8 | 12 |

BF-2000OM | Ø2000 | 10500 | 7200 | 3100 | 29.8 | 15 |

BF-2500OM | Ø2500 | 13000 | 8500 | 4600 | 41.8 | 19 |

BF-3000OM | Ø3000 | 15000 | 10000 | 4800 | 41.8 | 23 |

| BF-3500OM | Ø3500 | 17000 | 11000 | 5000 | 59.3 | 27 |

| BF-4000OM | Ø4000 | 19000 | 12000 | 5400 | 63.8 | 31 |

| BF-4500OM | Ø4500 | 20500 | 13000 | 5900 | 70.3 | 36 |

| BF-5000OM | Ø5000 | 22500 | 14500 | 6400 | 71.8 | 45 |

Machinery type: | Oven moveable shuttle rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Delivery time: | 90 days. |

Burner system: | Riello RS100 |

Cooling mode: | Fan cooling OR water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Arm quantity: | 3 Arms, can be straight arm or L arm. |

Warranty: | Whole parts one year. Big arm, PLC, Inverter, motors 18months |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

An oven moveable shuttle machine, also known as a shuttle oven rotational molding machine, is a type of rotomolding machine that utilizes a shuttle system to transfer molds in and out of the oven during the rotational molding process.

In a shuttle oven machine, the oven chamber is moveable, while the molds are moved in and out of the oven for heating, cooling, and demolding. The shuttle system typically consists of a mechanical or hydraulic mechanism that transports the molds between the oven and the loading/unloading stations.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-1000OM | Ø1000 | 6500 | 4500 | 1900 | 20.8 | 8 |

BF-1600OM | Ø1600 | 9000 | 6000 | 2900 | 29.8 | 12 |

BF-2000OM | Ø2000 | 10500 | 7200 | 3100 | 29.8 | 15 |

BF-2500OM | Ø2500 | 13000 | 8500 | 4600 | 41.8 | 19 |

BF-3000OM | Ø3000 | 15000 | 10000 | 4800 | 41.8 | 23 |

| BF-3500OM | Ø3500 | 17000 | 11000 | 5000 | 59.3 | 27 |

| BF-4000OM | Ø4000 | 19000 | 12000 | 5400 | 63.8 | 31 |

| BF-4500OM | Ø4500 | 20500 | 13000 | 5900 | 70.3 | 36 |

| BF-5000OM | Ø5000 | 22500 | 14500 | 6400 | 71.8 | 45 |

Machinery type: | Oven moveable shuttle rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Delivery time: | 90 days. |

Burner system: | Riello RS100 |

Cooling mode: | Fan cooling OR water cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Arm quantity: | 3 Arms, can be straight arm or L arm. |

Warranty: | Whole parts one year. Big arm, PLC, Inverter, motors 18months |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |