- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-2000TL

SNOWBALL

8477.4010.00

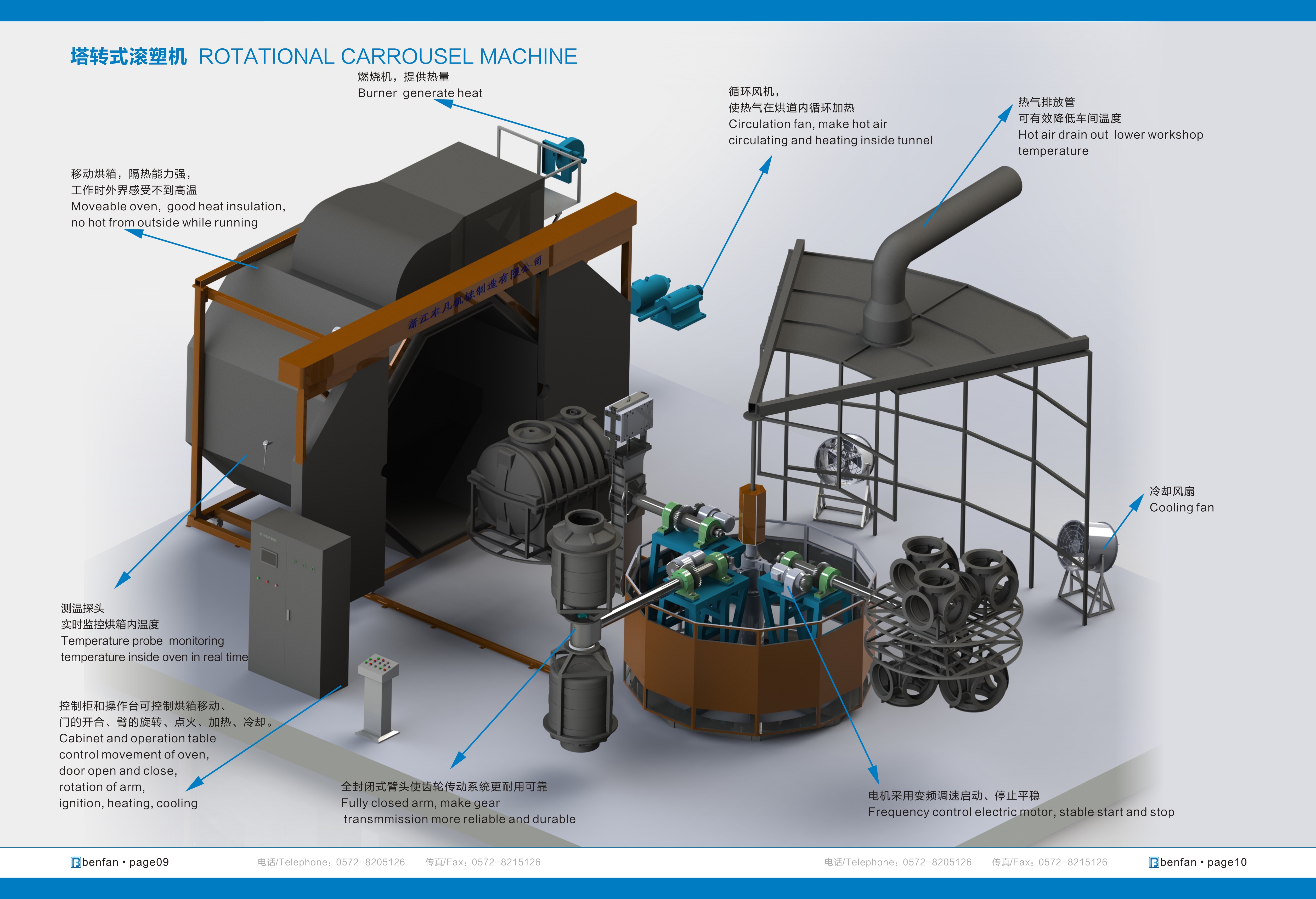

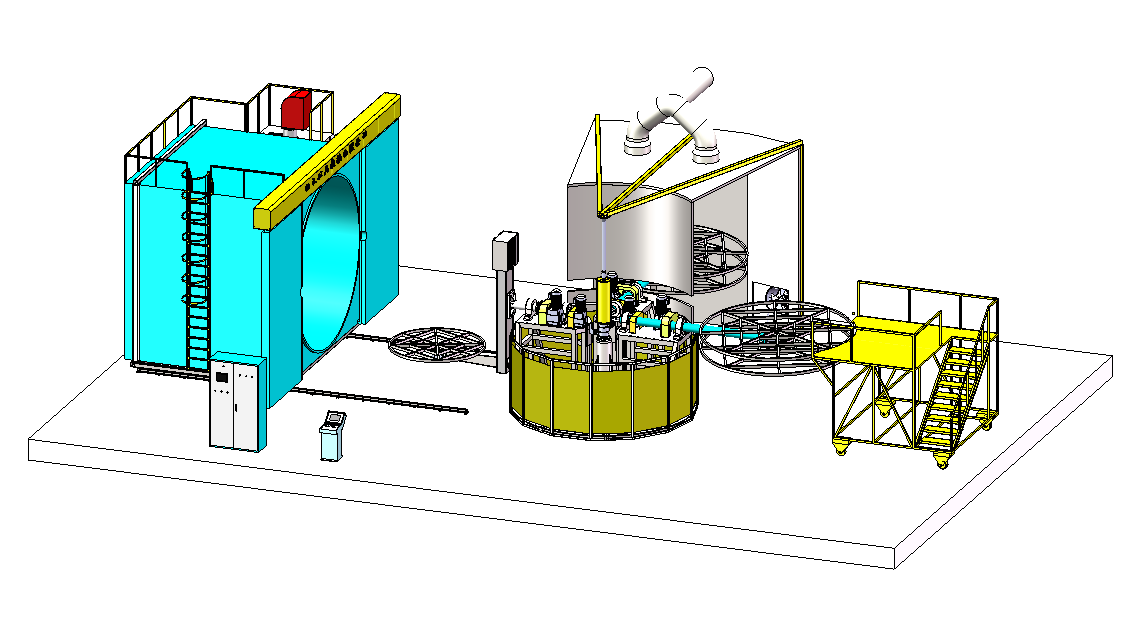

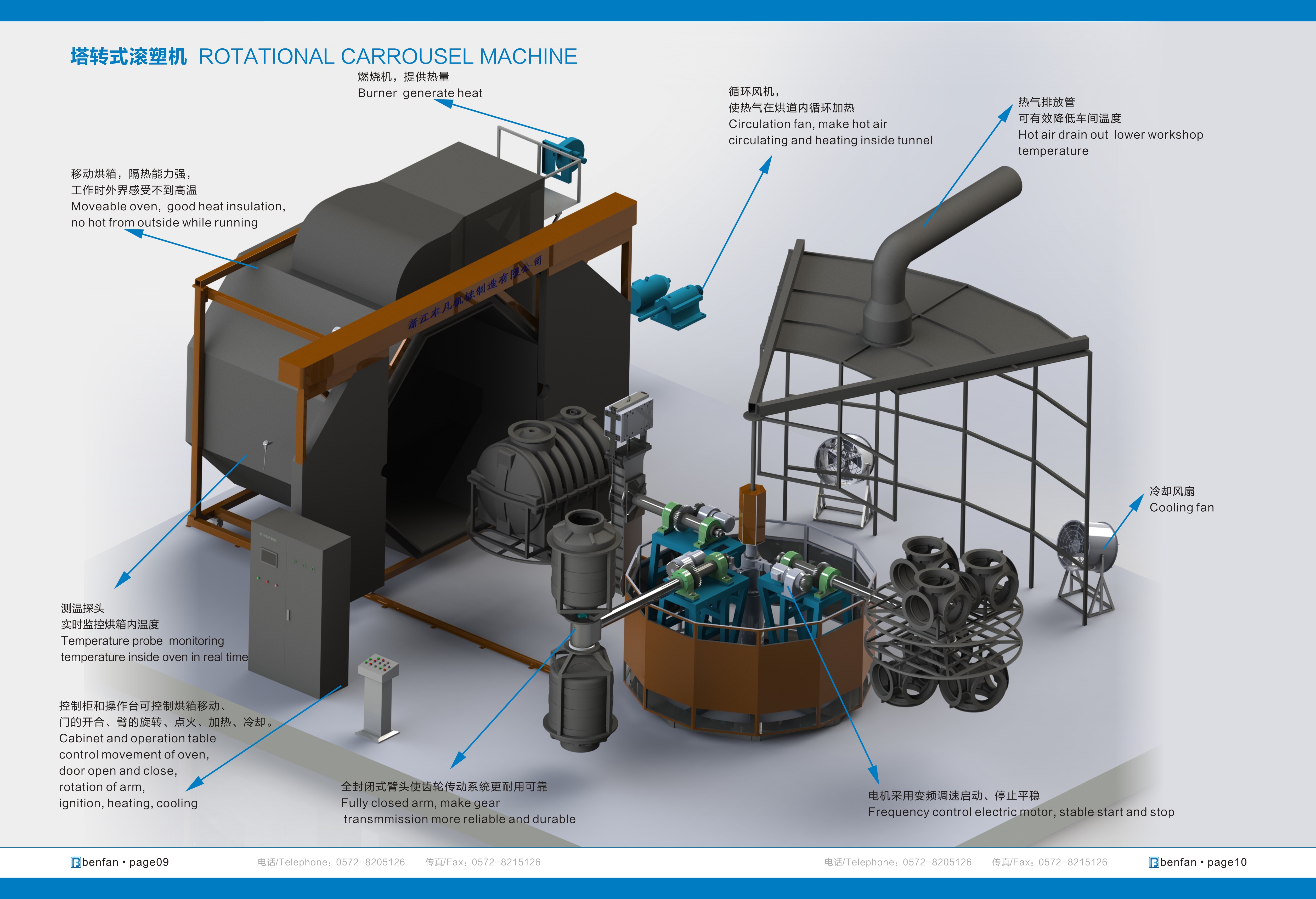

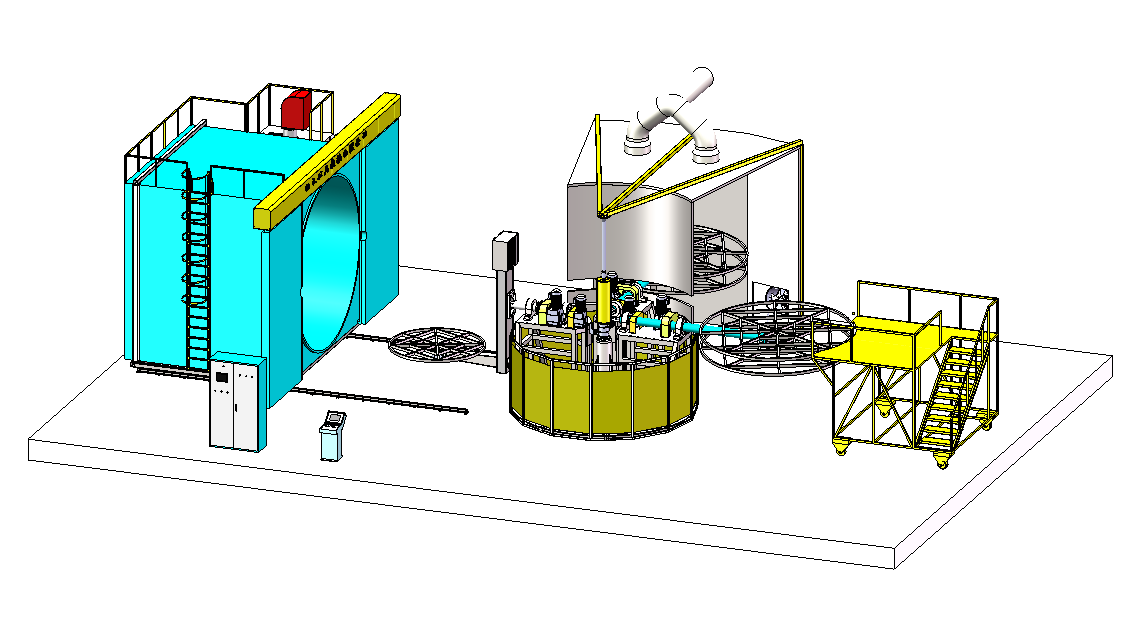

Rotational molding machines are commonly used to produce a wide range of plastic products, such as tanks, containers, playground equipment, automotive components, and more. The process offers several advantages, including the ability to create large, complex, and hollow parts with uniform wall thickness. It is a cost-effective method for producing low-volume or custom-designed products.

Rotational molding machines come in various sizes and configurations to accommodate different production needs. They are widely used in industries such as automotive, aerospace, agriculture, and consumer goods for manufacturing plastic parts with high quality and consistency.

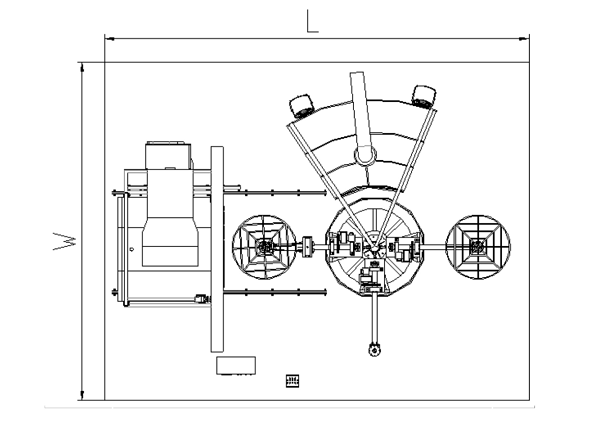

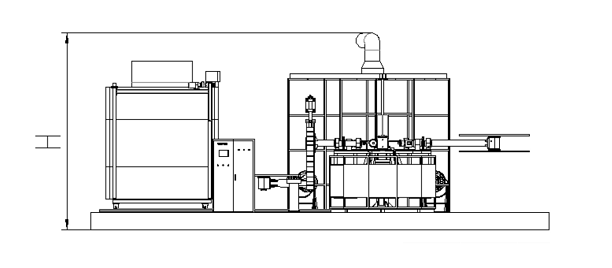

Technical data sheet:

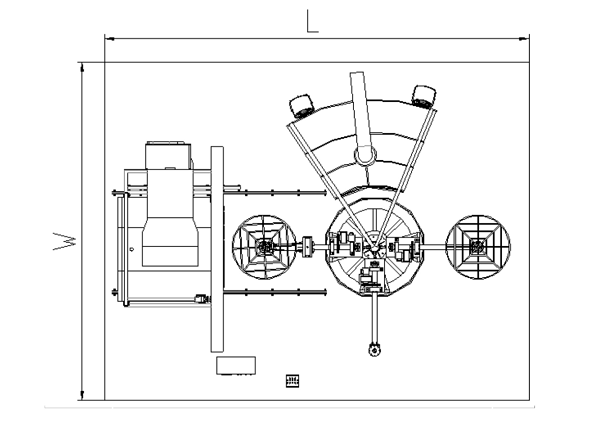

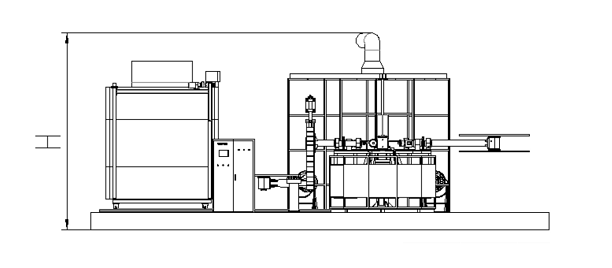

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |

Rotational molding machines are commonly used to produce a wide range of plastic products, such as tanks, containers, playground equipment, automotive components, and more. The process offers several advantages, including the ability to create large, complex, and hollow parts with uniform wall thickness. It is a cost-effective method for producing low-volume or custom-designed products.

Rotational molding machines come in various sizes and configurations to accommodate different production needs. They are widely used in industries such as automotive, aerospace, agriculture, and consumer goods for manufacturing plastic parts with high quality and consistency.

Technical data sheet:

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Biggest tank made | ||

L | W | H | ||||

SN-2000TL | Ø2000 | 10000 | 8000 | 3500 | 24.75 | 1000L |