- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SN-4500TL

SNOWBALL

8477.4010.00

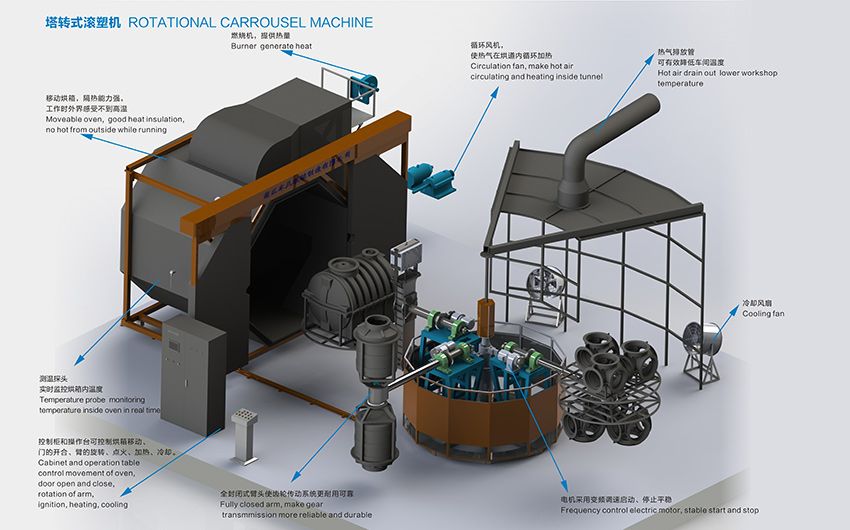

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular. With 3 or 4 hands, the output capacity can be higher 30% than shuttle rotomolding machine.

Half round safety fences,after the platform forward and stop, it will turn over automatic, make sure workers

on the arm dish be safe.

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 30 | 12 |

BF-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 16 |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS 100 |

Cooling mode: | Fan cooling and moist cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 90 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

The number of workers required for operating a rotomolding machine can vary depending on several factors, including the size and complexity of the machine, the production volume, and the level of automation in the production process. Generally, a rotomolding machine can be operated by a small team of workers, typically consisting of:

1. Machine Operator: The machine operator is responsible for setting up the machine, loading the molds with plastic material, monitoring the production process, and ensuring the machine operates smoothly. They need to have a good understanding of the rotomolding process, machine controls, and troubleshooting techniques.

2. Mold Technician: A mold technician is responsible for preparing and maintaining the molds used in the rotomolding process. They ensure that the molds are clean, properly heated, and in good condition before each production cycle. They may also assist with mold changes and repairs.

3. Material Handler: The material handler is responsible for managing the supply of plastic resins, additives, and colorants to the rotomolding machine. They ensure that the materials are properly stored, transported, and loaded into the machine as needed. They may also assist with material mixing and handling scrap or excess material.

4. Quality Control Inspector: A quality control inspector monitors the quality of the molded products, checking for any defects, inconsistencies, or issues. They may perform visual inspections, measurements, and other quality checks to ensure that the products meet the required specifications and standards.

In some cases, especially for larger or more automated rotomolding operations, additional workers may be required for tasks such as mold changes, maintenance, auxiliary machine operation, or packaging and shipping of the finished products.

It is important to note that the specific number of workers required can vary based on the specific production requirements, the level of automation, and the efficiency of the production process. It is recommended to assess the production needs and consult with the machine manufacturer or industry experts to determine the optimal number of workers for a particular rotomolding machine setup.

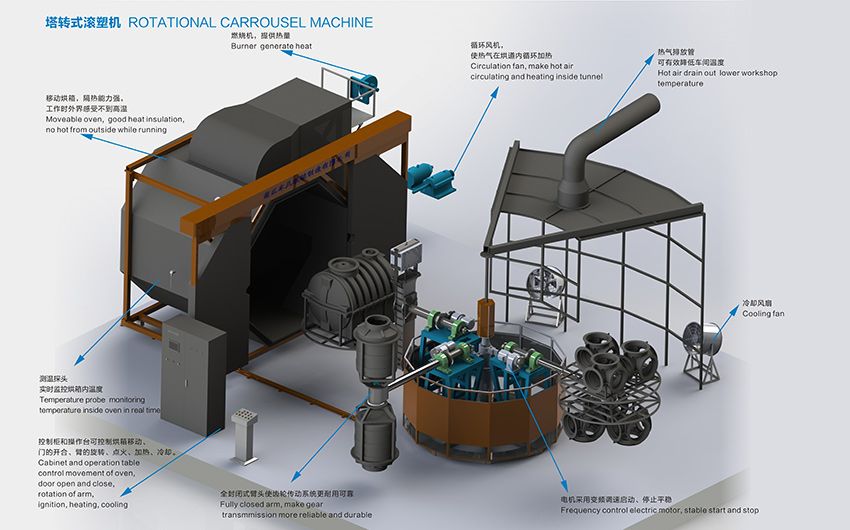

Carrousel rotomoulding machine is common molding equipment and each arm’s working and technological circle(rotating speed,heating temperature and time,cooling) is independent from other arms.It is fit for making products with different materials,thickness,which is flexible and high efficiency.

This carrousel rotomolding machine oven can be moveable. Its shape is round. There is only one door, so it is energy-saving and popular. With 3 or 4 hands, the output capacity can be higher 30% than shuttle rotomolding machine.

Half round safety fences,after the platform forward and stop, it will turn over automatic, make sure workers

on the arm dish be safe.

Model No. | Oven Size(mm) | Machine Dimensions(mm) | Total Power (kw) | Total weight(Ton) | ||

L | W | H | ||||

BF-2000ZC | Ø2000 | 10000 | 8000 | 3500 | 30 | 12 |

BF-2500ZC | Ø2500 | 13500 | 9000 | 4000 | 35 | 16 |

Machinery type: | Carrousel rotomolding machine |

Heating supply: | Natural gas,liquefied gas,diesel oil |

Temperature control: | DTE Control±2℃ |

Burner system: | Riello RS 100 |

Cooling mode: | Fan cooling and moist cooling |

Control mode: | Touch screen+PLC(Siemens brand) |

Electric brand: | Schneider,Omron |

Delivery time: | About 90 days after receive the deposit |

Overseas Installation period | It depends on machine size,usually takes 10-20days |

Heating rate: | 3 miniutes from room temperature to 280 degree in oven |

The number of workers required for operating a rotomolding machine can vary depending on several factors, including the size and complexity of the machine, the production volume, and the level of automation in the production process. Generally, a rotomolding machine can be operated by a small team of workers, typically consisting of:

1. Machine Operator: The machine operator is responsible for setting up the machine, loading the molds with plastic material, monitoring the production process, and ensuring the machine operates smoothly. They need to have a good understanding of the rotomolding process, machine controls, and troubleshooting techniques.

2. Mold Technician: A mold technician is responsible for preparing and maintaining the molds used in the rotomolding process. They ensure that the molds are clean, properly heated, and in good condition before each production cycle. They may also assist with mold changes and repairs.

3. Material Handler: The material handler is responsible for managing the supply of plastic resins, additives, and colorants to the rotomolding machine. They ensure that the materials are properly stored, transported, and loaded into the machine as needed. They may also assist with material mixing and handling scrap or excess material.

4. Quality Control Inspector: A quality control inspector monitors the quality of the molded products, checking for any defects, inconsistencies, or issues. They may perform visual inspections, measurements, and other quality checks to ensure that the products meet the required specifications and standards.

In some cases, especially for larger or more automated rotomolding operations, additional workers may be required for tasks such as mold changes, maintenance, auxiliary machine operation, or packaging and shipping of the finished products.

It is important to note that the specific number of workers required can vary based on the specific production requirements, the level of automation, and the efficiency of the production process. It is recommended to assess the production needs and consult with the machine manufacturer or industry experts to determine the optimal number of workers for a particular rotomolding machine setup.